Thermally conductive adhesive with high glass transition temperature and preparation method thereof

A technology of high vitrification and heat-conducting adhesive, which is applied in the field of heat-conducting adhesive, can solve the problems of gradient temperature difference of optical fiber ring, affecting the accuracy of optical fiber gyroscope, affecting the stability of the zero bias of optical fiber gyroscope, etc., to reduce the temperature difference, reduce the curing shrinkage rate, moisten Good wet leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

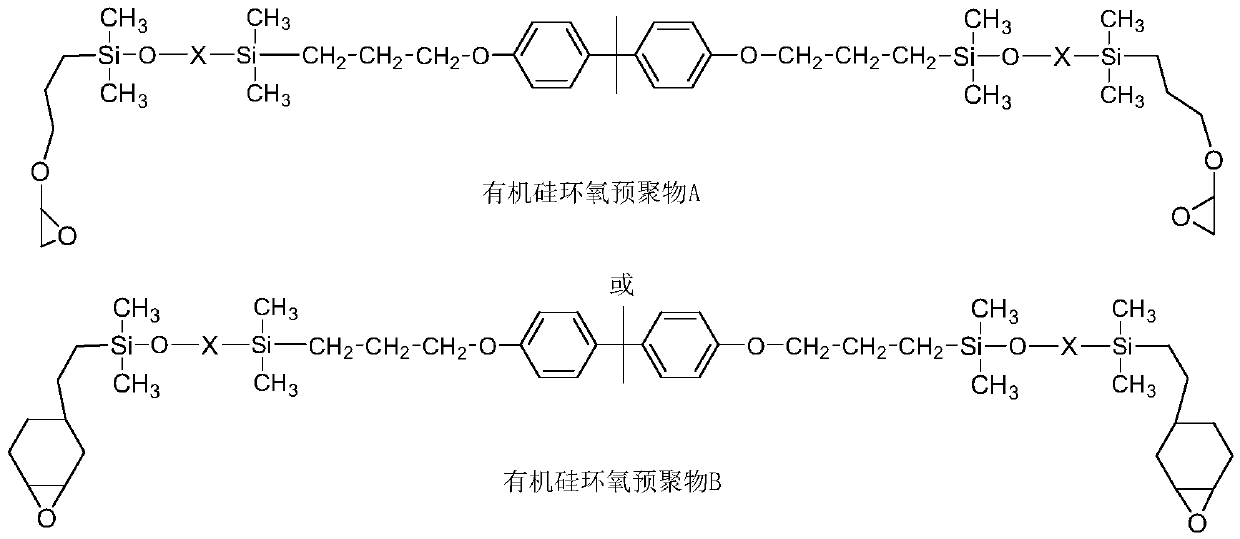

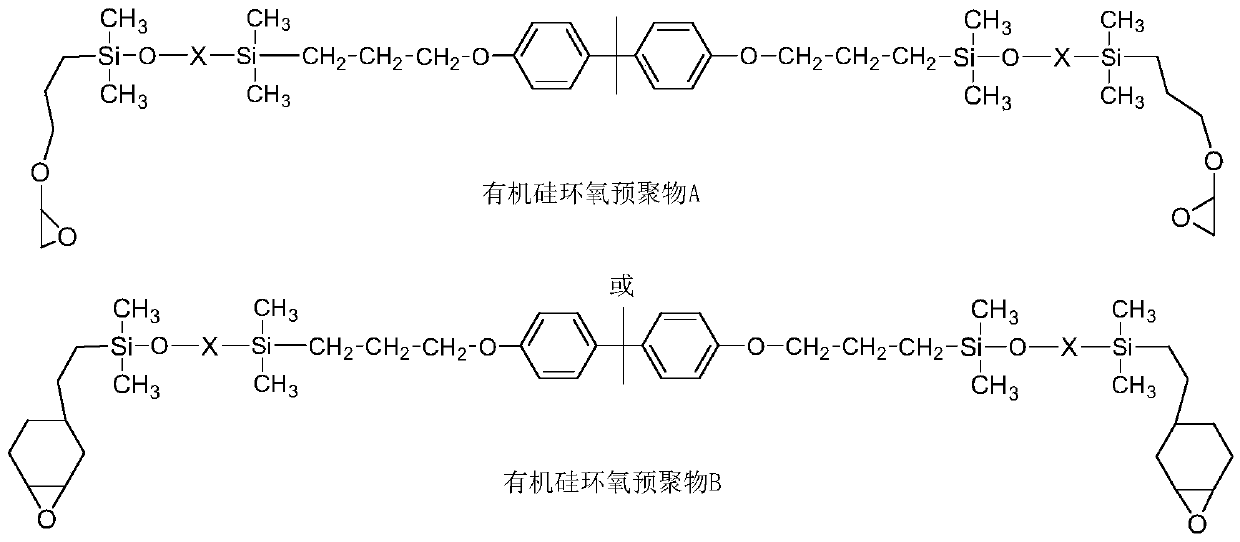

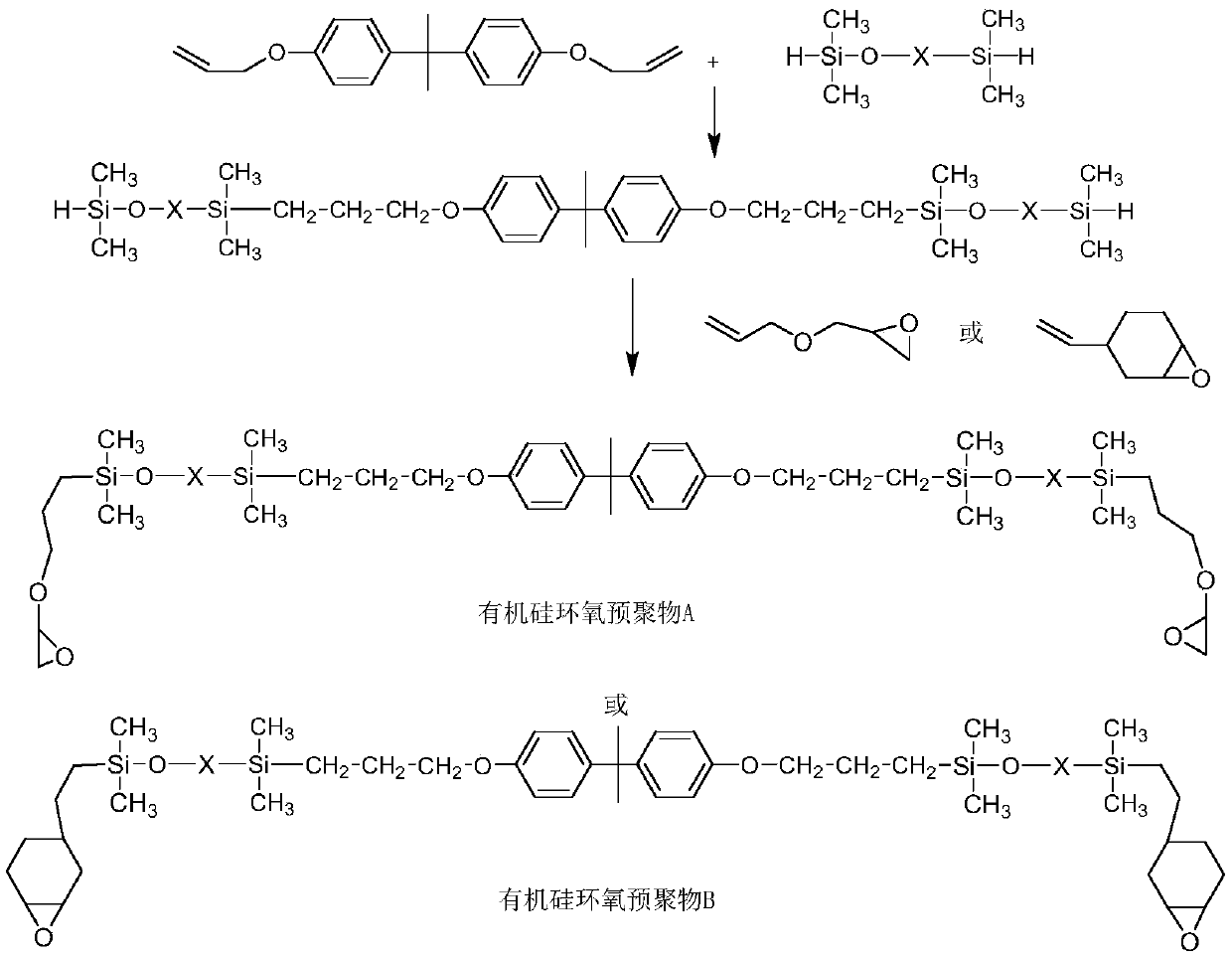

[0035] (1) Preparation of organosilicon epoxy prepolymer A

[0036] 344g terminal hydrogen-containing phenyl silicone oil Add 308.42g of allyl bisphenol A into the flask, add 100ppm platinum catalyst KP36 relative to the total mass, react at a temperature of 120°C for 3 hours, then add 114.14g of allyl glycidyl ether and continue the reaction for 4 hours to obtain the product with a viscosity of 25℃265mpa.s.

[0037] (2) Preparation of organosilicon epoxy prepolymer B

[0038] 208g terminal hydrogen-containing silicone oil Add 308.42g of allyl bisphenol A into the flask, add 150ppm platinum catalyst KP36 relative to the total mass, react at a temperature of 130°C for 2 hours, and then add 124.18g of 4-vinyl-1-cyclohexene-1,2- The epoxy continued to react for 3 hours to obtain a product with a viscosity of 176mpa.s at 25°C.

[0039] (3) Preparation of thermally conductive adhesive

[0040] The mass ratio of the raw materials of each component of the thermal conductive adh...

Embodiment 2

[0043] Step (1) (2) is consistent with embodiment 1.

[0044] (3) Preparation of thermally conductive adhesive

[0045] The mass ratio of the raw materials of each component of the thermal conductive adhesive is: silicone epoxy prepolymer A 4%, silicone epoxy prepolymer B6%, alicyclic epoxy resin UVR-6128 2%, 3-ethyl-3 -Oxetanemethanol 2%, macromolecular polyol PTMG6502%, curing agent Anyhard 1010P 3.52%, antioxidant 1726 0.1%, light stability UV-9 0.1%, thermally conductive filler acicular alumina 10%, thermally conductive filler Spherical alumina 70%, TiloJet 3000 0.08%, coupling agent AL-M (aluminate) 0.2%, the sum of each component meets 100%.

[0046] Weigh the above-mentioned raw materials in proportion, add all materials except curing agent and thermal conductive filler into the mixing tank, and then add thermal conductive filler while stirring. After all the thermal conductive fillers are added, use an ultrasonic processor for 25 minutes, and then wait for the materia...

Embodiment 3

[0048] Step (1) (2) is consistent with embodiment 1.

[0049] (3) Preparation of thermally conductive adhesive

[0050] The mass ratio of the raw materials of each component of the thermal conductive adhesive is: silicone epoxy prepolymer A 30%, silicone epoxy prepolymer B 5%, cycloaliphatic epoxy resin UVR-6128 12%, 3-oxetane Alkanol 12%, macromolecular polyol PCL305 11%, curing agent ICAM-8409 0.5%, defoamer DC-163 0.1%, antioxidant 1010 0.16%, light stability UV-5310.15%, thermally conductive filler graphene 8%, thermal conductive filler spherical boron nitride 20%, TiloJet 3003 0.59%, coupling agent isopropyl triisostearyl titanate 0.5%, the sum of each component meets 100%.

[0051] Weigh the above-mentioned raw materials in proportion, add all materials except curing agent and thermal conductive filler into the mixing tank, and then add thermal conductive filler while stirring. After all the thermal conductive fillers are added, use an ultrasonic processor for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com