Method for fermenting vegetable soybeans and other foreign products by bacillus natto to produce nattokinase

A technology for producing nattokinase and vegetable soybeans, which is applied in the field of microbial fermentation, can solve problems such as uncertain production conditions, and achieve the effects of simple fermentation conditions, good thrombolytic effect in vitro, and high enzyme production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for producing nattokinase by bacillus natto fermenting vegetable soybeans and other foreign products, comprising:

[0038] (1) Raw material processing: After selection, washing and weighing of vegetable soybeans and other foreign products, put them into a sterilizing pot for sterilizing by high-pressure steam at 121°C for 20 minutes and steam them until cooked;

[0039] (2) Inoculation: Bacillus subtilis natto bacterium liquid is mixed with natto bacterium powder with warm water, inoculated by 2% of the weight of foreign products such as vegetable soybeans, and the bacterium liquid is poured into when the temperature of beans is maintained at 50°C;

[0040] (3) Fermentation: Put the foreign products such as vegetable soybeans poured into the bacterial liquid into a constant temperature incubator at 37°C to ferment for 36 hours,

[0041] (4) post-ripening: after the fermentation is completed, place it in a refrigerator at 4°C for post-ripening for 18 hours to ob...

Embodiment 2

[0046] Determination of plasmin activity.

[0047] 1. Agarose-fibrin plate method

[0048] 1. Preparation of fibrin plate: refer to the method of Astrup et al. and improve it. Dissolve 0.3% fibrinogen in 10 mL pH 7.4 phosphate buffer solution and keep warm at 50°C for 5-10 min. Dissolve 20 U of thrombin in 1 mL of pH 7.4 phosphate buffer solution to prepare thrombin buffer solution. Prepare 1.5% agarose solution, keep it warm at 50°C for 10 minutes, mix 1mL 20U / mL thrombin buffer solution, 10mL fibrinogen solution and 10mL agarose solution quickly, pour the plate immediately, and punch holes after solidification. Dilute the sample on a fibrin plate, and measure the diameter of the fibrinolytic circle with a vernier caliper after incubating in a 37°C incubator for 18 hours.

[0049] 2. Drawing of the standard curve: Dilute the urokinase standard product accordingly to a concentration gradient of 100, 200, 400, 800, 1600 IU / mL, spot the sample on the prepared fibrin plate, an...

Embodiment 3

[0054] Single-factor experiment on the production of nattokinase from vegetable soybean fermented by Bacillus natto.

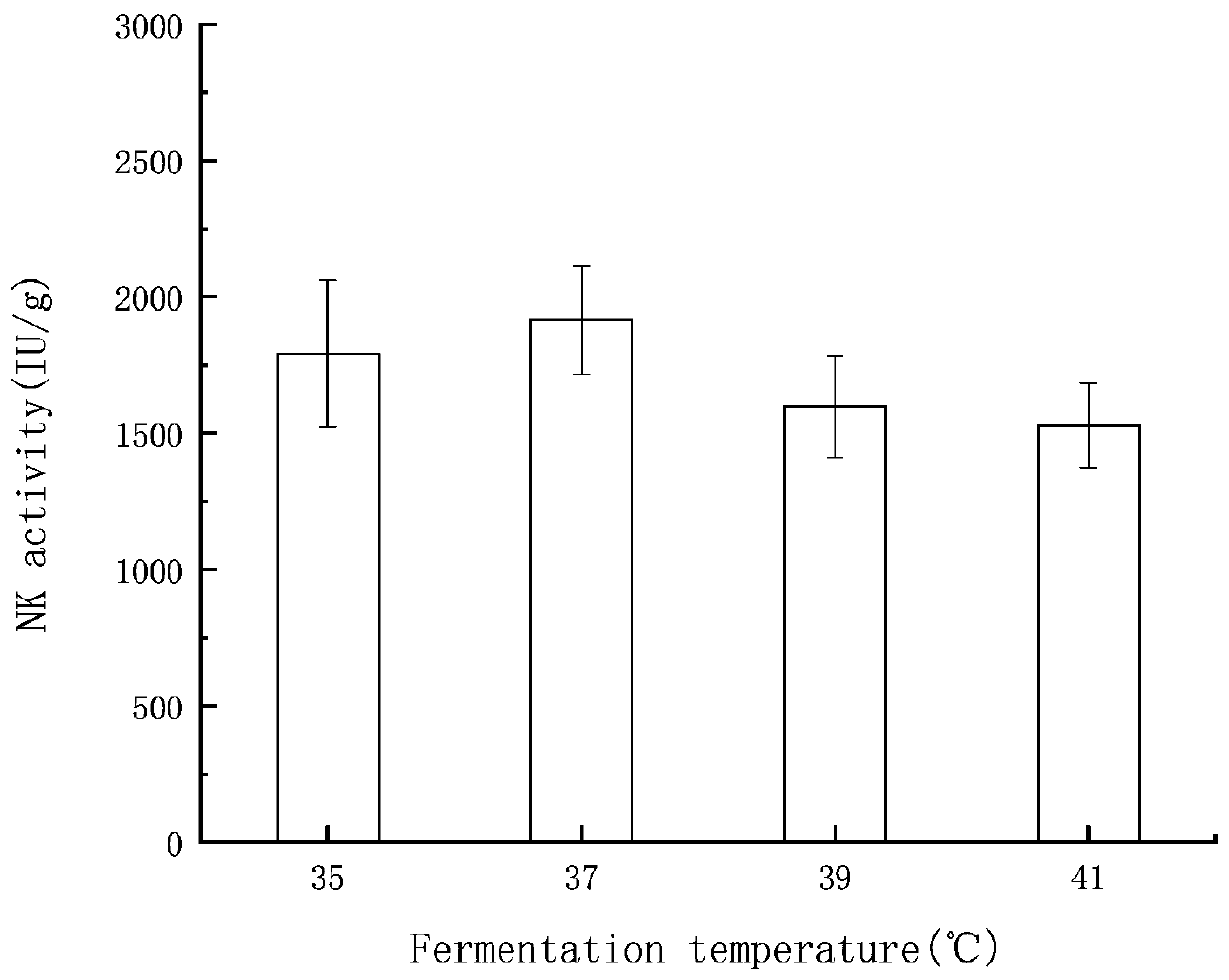

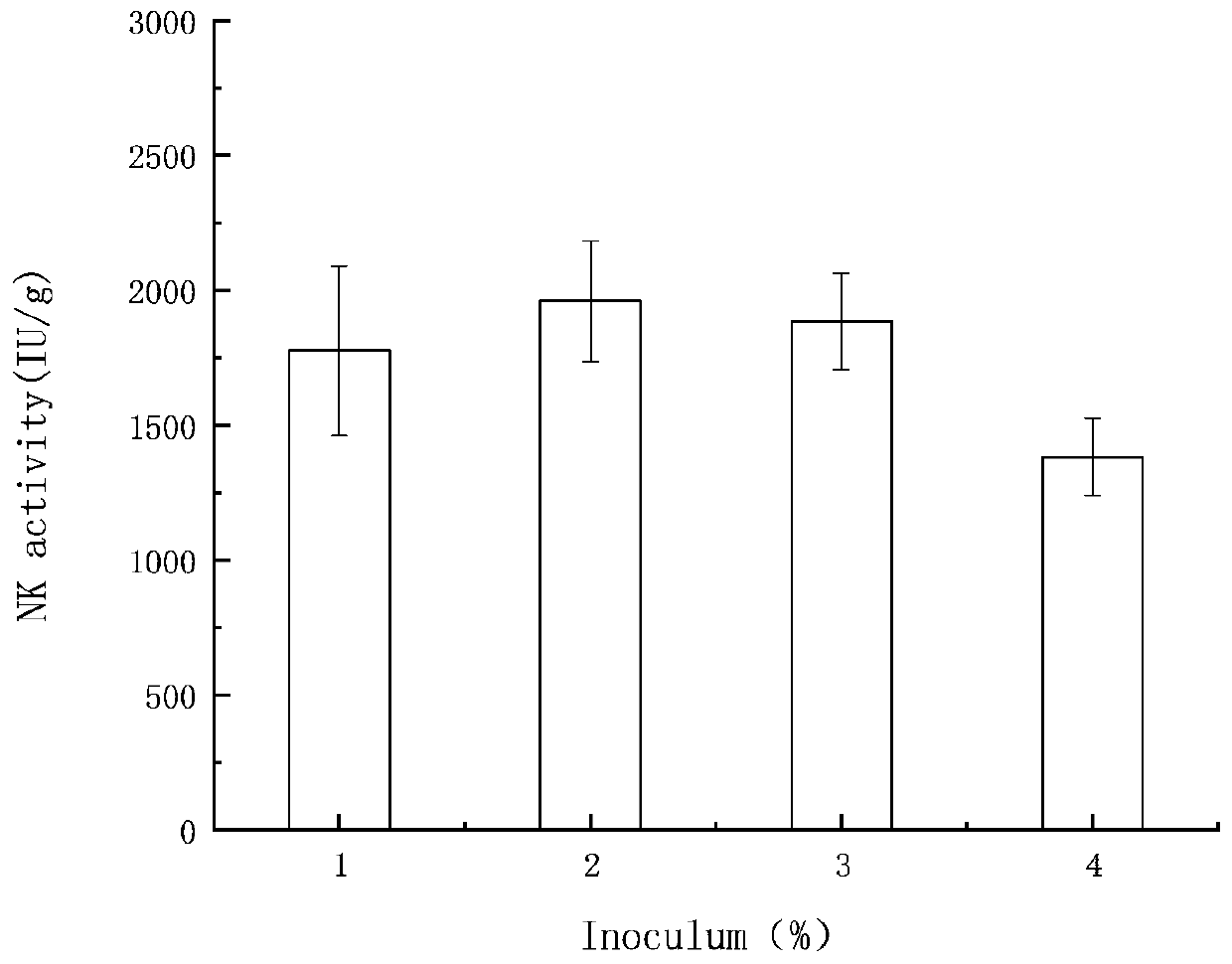

[0055] Bacillus natto was inoculated in steamed vegetable soybeans for fermentation, and the effects of four factors including fermentation time, inoculum size, fermentation temperature and post-ripening time on the activity of nattokinase were investigated. After being screened by each single factor experiment, it provides the preliminary experimental basis for the next orthogonal optimization experiment.

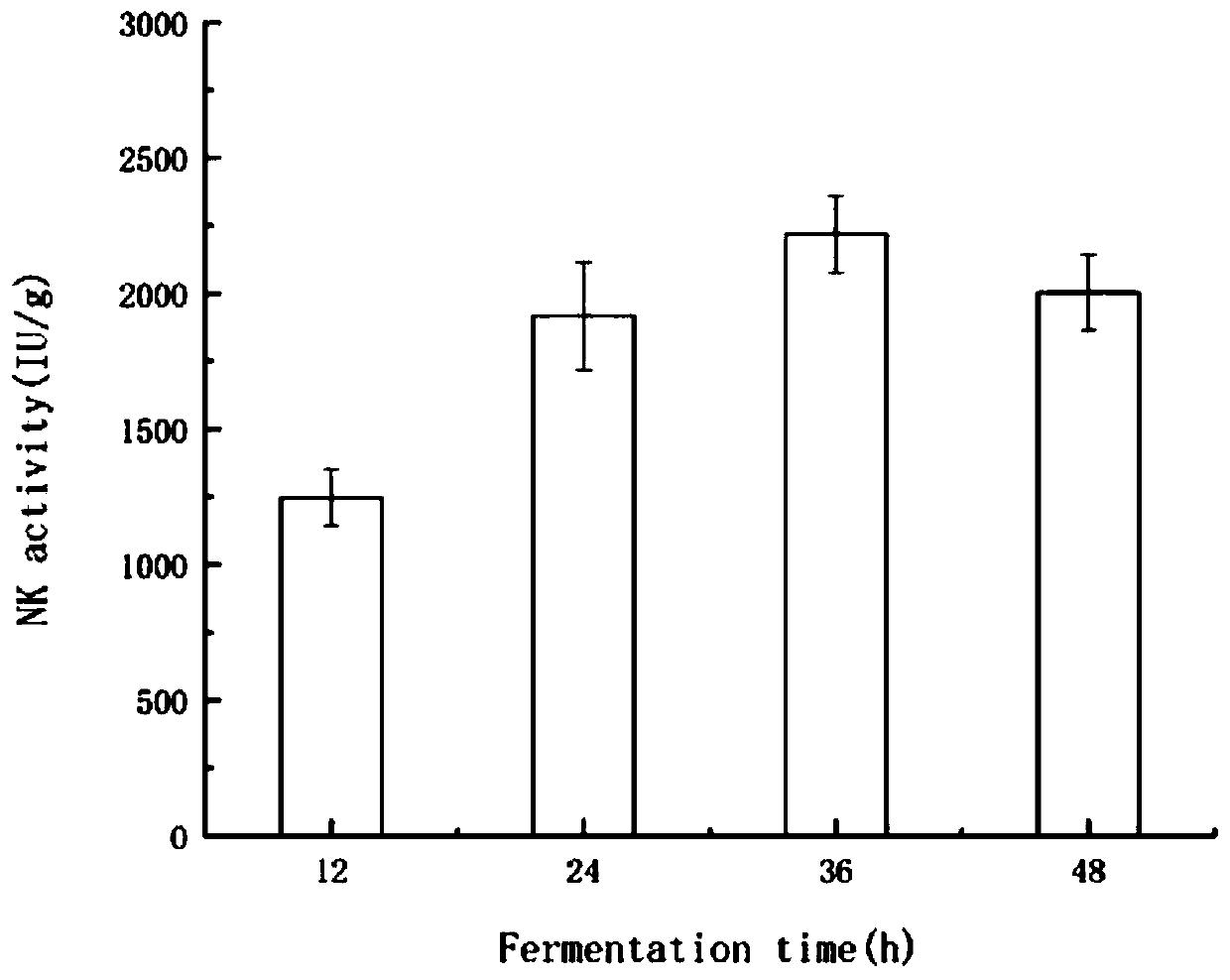

[0056] 1. Effect of fermentation time on nattokinase activity

[0057] Inoculate 2% Bacillus natto bacteria liquid into sterilized and steamed vegetable soybeans, put them into a constant temperature incubator with a preset temperature of 37°C, and cultivate them for 12h, 24h, 36h and 48h respectively, and put them into After ripening in a refrigerator at 4°C for 12 hours, three parallel experiments were carried out for each group, and then the finished p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com