Titanium carbide based metal ceramic thermal spray powder and preparation method

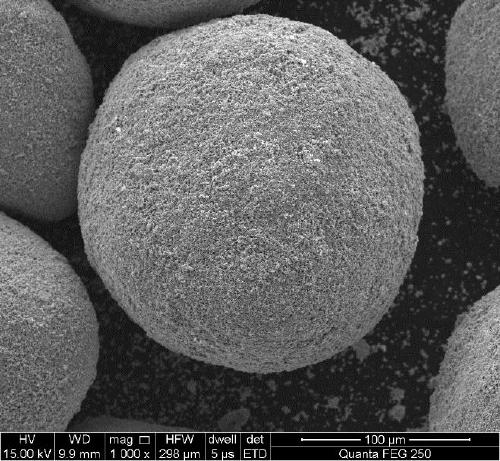

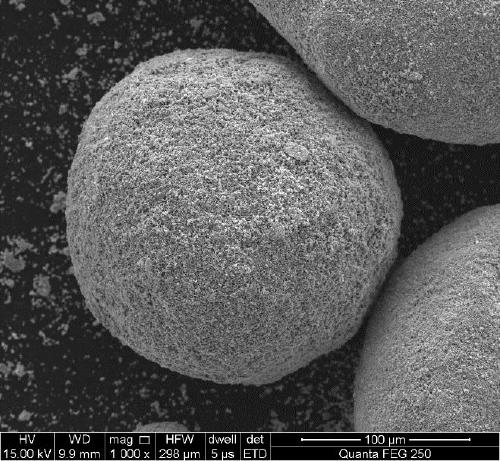

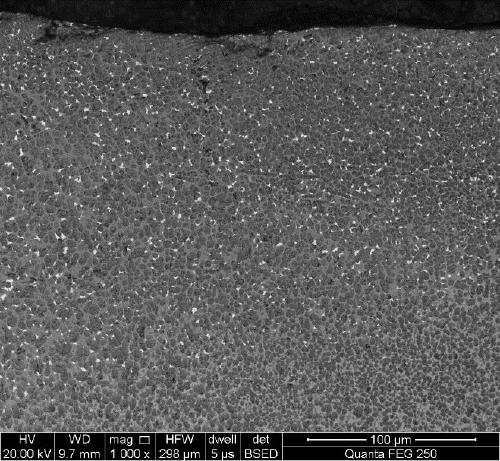

A technology for thermal spraying powder and ceramic powder, applied in metal processing equipment, metal material coating process, coating and other directions, can solve the problems of uneven metal coating, poor composition uniformity, low powder density, etc., and achieve sphericity. High, high powder density, good composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Include the following steps:

[0067] (1) Wet grinding (ball-to-material ratio: 5:1):

[0068] ① Put TiC, TiN, WC, Mo 2 C, Co and Ni are added in the ball mill tank according to the proportion, then add adhesive and wet milling medium, and ball mill at a speed of 60r / min for 48h to obtain a uniformly mixed slurry;

[0069] Among them, the adhesive is paraffin, and the amount of the adhesive is TiC, TiN, WC, Mo 2 4% of the total weight of C, Co and Ni; the wet grinding medium adopts absolute ethanol, and its addition is to be able to immerse all the main material powders and grinding balls; the material of the grinding balls is cemented carbide;

[0070] ②Dry the slurry obtained in step ① in a vacuum oven with a vacuum degree of 70Pa and a drying temperature of 80°C for 4 hours to obtain a dry and uniform mixed powder;

[0071] (2) Differential sieve granulation:

[0072] ①Put the mixed powder obtained in step (1) into a constant temperature stirring machine dish, ke...

Embodiment 2

[0089] Include the following steps:

[0090] (1) Wet grinding (ball-to-material ratio: 4.5:1):

[0091] ① Put TiC, TiN, WC, Mo 2 C, Co and Ni are added in the ball mill tank according to the proportion, then add adhesive and wet milling medium, and ball mill at a speed of 60r / min for 48h to obtain a uniformly mixed slurry;

[0092] Among them, the adhesive is paraffin or polyethylene glycol, and the amount of the adhesive is TiC, TiN, WC, Mo 2 4% of the total weight of C, Co and Ni; the wet grinding medium adopts absolute ethanol, and its addition is to be able to immerse all the main material powders and grinding balls; the material of the grinding balls is cemented carbide;

[0093] ②Dry the slurry obtained in step ① in a vacuum oven with a vacuum degree of 70Pa and a drying temperature of 80°C for 4 hours to obtain a dry and uniform mixed powder;

[0094] (2) Differential sieve granulation:

[0095] ①Put the mixed powder obtained in step (1) into a constant temperature ...

Embodiment 3

[0110] Include the following steps:

[0111] (1) Wet grinding (ball-to-material ratio: 4.5:1):

[0112] ① Put TiC, TiN, WC, Mo 2 C, Co and Ni are added in the ball mill tank according to the proportion, then add adhesive and wet milling medium, and ball mill at a speed of 60r / min for 48h to obtain a uniformly mixed slurry;

[0113] Among them, the adhesive is paraffin or polyethylene glycol, and the amount of the adhesive is TiC, TiN, WC, Mo 2 4% of the total weight of C, Co and Ni; the wet grinding medium adopts absolute ethanol, and its addition is to be able to immerse all the main material powders and grinding balls; the material of the grinding balls is cemented carbide;

[0114] ②Dry the slurry obtained in step ① in a vacuum oven with a vacuum degree of 70Pa and a drying temperature of 80°C for 4 hours to obtain a dry and uniform mixed powder;

[0115] (2) Differential sieve granulation:

[0116] ①Put the mixed powder obtained in step (1) into a constant temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com