Implant material and preparation method and application thereof

A technology for implants and oral implants, applied in prosthesis, medical science, coating, etc., can solve problems such as easy infection and implant surgery failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Another aspect of the present invention provides a preparation method of implant material, and the preparation method comprises the following steps:

[0045]1) adding titanium rods and / or titanium sheets to an electrolyte containing calcium salts and phosphates for plasma oxidation treatment to prepare TiO 2 coating;

[0046] 2) adding zinc salt and strontium salt to the electrolyte solution described in step 1) to prepare the implant material.

[0047] In the preparation method of the implant material provided by the present invention, step 1) is to add titanium rods and / or titanium sheets to an electrolyte containing calcium salts and phosphates for plasma oxidation treatment to prepare TiO 2 coating. The titanium rod and titanium sheet need to be pre-treated, and the pre-treatment includes grinding and polishing 10mm×10mm×1mm or 20mm×20mm×1mm of commercial pure titanium or 2mm×7mm cylindrical commercial pure titanium, Wash with ethanol and deionized water in order...

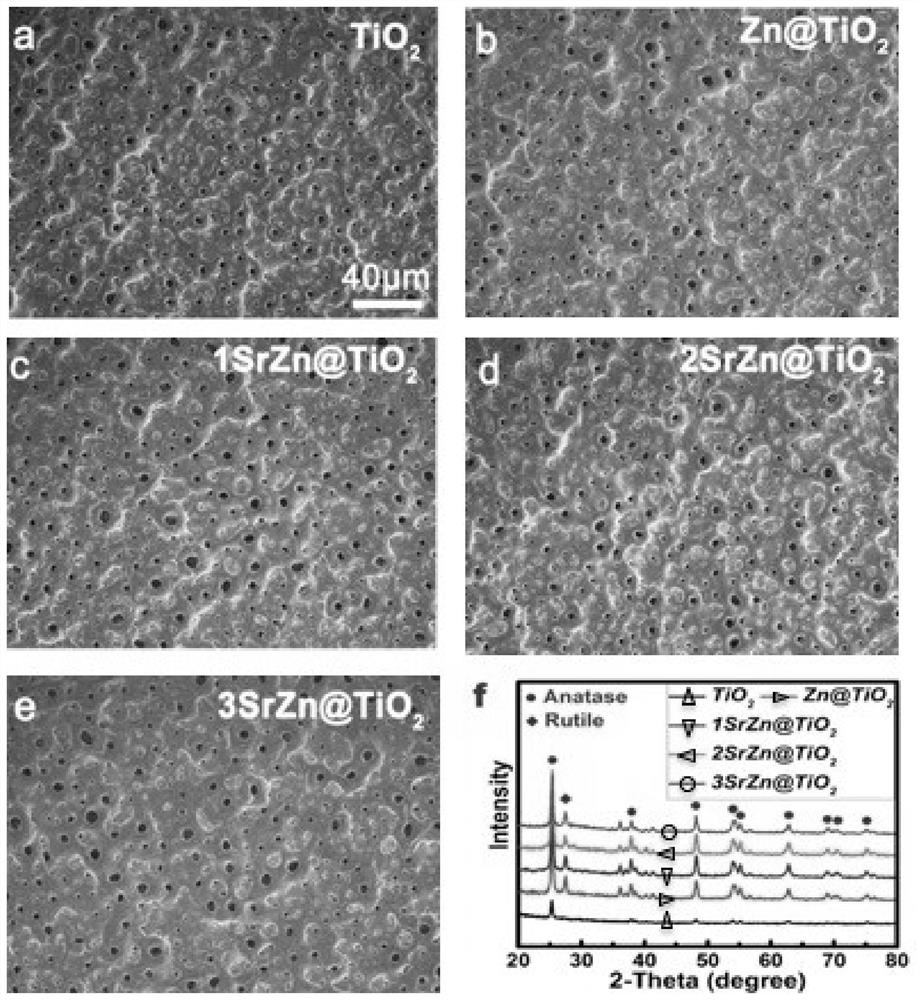

Embodiment 1

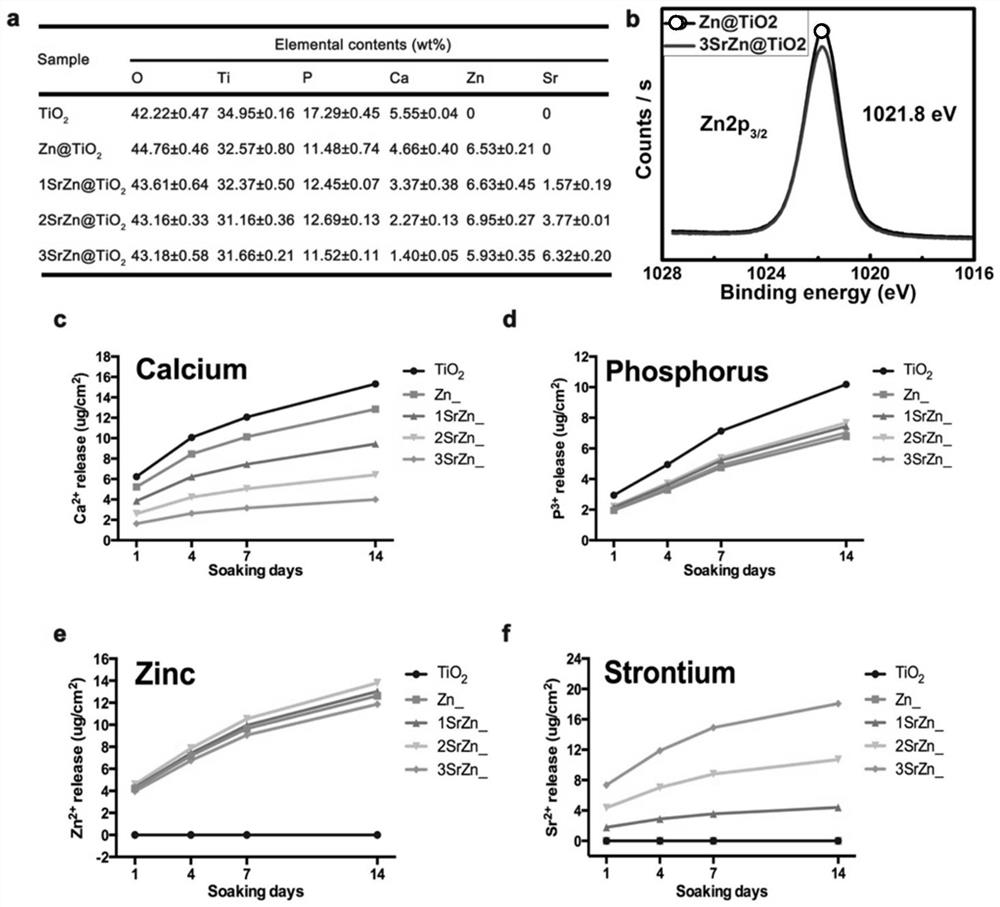

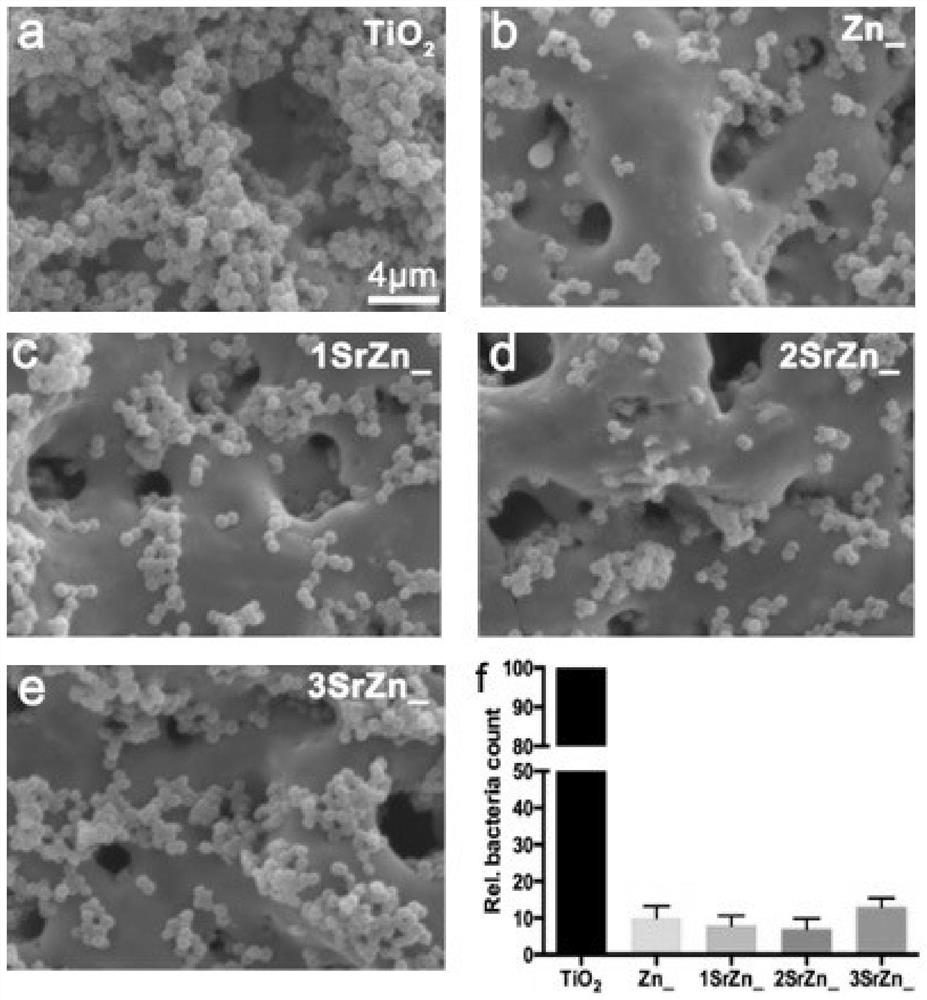

[0061] Add β-glycerophosphate disodium salt (C 3 H 7 Na 2 O 6 P·5H 2 O, 50 mM) and calcium acetate monohydrate (C 4 H 6 O 4 Ca·H 2 O), configure the electrolyte containing calcium / phosphate, treat the titanium rod by plasma oxidation in the electrolyte containing calcium / phosphate, the titanium sheet is the anode, and the constant current with a duty ratio of 10% and a frequency of 800Hz is used The plasma electrolytic oxidation power supply, the current density is 30A / dm 2 , oxidized for 10 min to prepare TiO 2 coating. Continue to add zinc acetate (60 mM) and strontium acetate to the above electrolyte, wherein the total concentration of calcium acetate and zinc acetate is constant at 100 mM, and the molar ratio of Sr:(Sr+Ca) is adjusted to 1:4. The prepared sample was named 1SrZn@TiO 2 . like figure 1 , XRD test proves that the prepared TiO 2 The coatings are mainly rutile and anatase phases. like figure 2 The EDS of a shows that the mass percentages of each...

Embodiment 2

[0063] Add β-glycerophosphate disodium salt (C 3 H 7 Na 2 O 6 P·5H 2 O, 50 mM) and calcium acetate monohydrate (C 4 H 6 O 4 Ca·H 2 O), configure the electrolyte containing calcium / phosphate, treat the titanium rod by plasma oxidation in the electrolyte containing calcium / phosphate, and use the titanium sheet as the anode, using a constant duty cycle of 10% and a frequency of 800Hz. Flow plasma electrolytic oxidation power supply with a current density of 30A / dm 2 , oxidized for 10 min to prepare TiO 2 coating. Continue to add zinc acetate (60 mM) and strontium acetate to the above electrolyte, wherein the total concentration of calcium acetate and zinc acetate is constant at 100 mM, and the molar ratio of Sr:(Sr+Ca) is adjusted to 2:4. The prepared sample was named 2SrZn@TiO 2 . like figure 1 As shown, XRD examinations confirmed that the as-prepared TiO 2 The coatings are mainly rutile and anatase phases. like figure 2 The EDS of a shows that the mass percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com