Beneficiation inhibitor and purification method of molybdenum rough concentrate

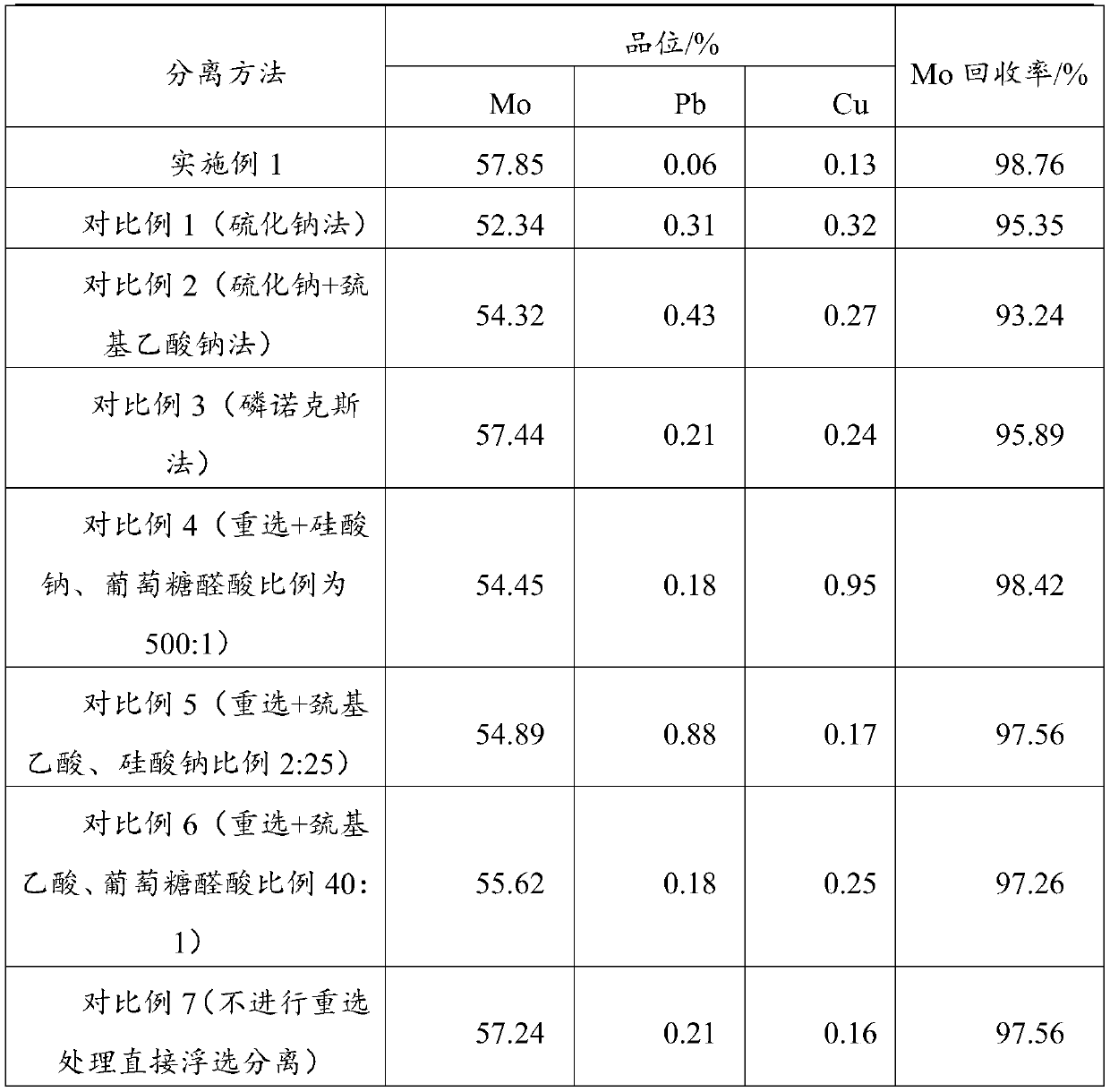

A purification method and inhibitor technology, applied in flotation, solid separation, etc., can solve the problems of application limitation, phosphoknox is highly toxic, etc., achieve strong inhibition, reduce impurity content, and reduce the pressure of subsequent lead reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw material is a molybdenum rough concentrate in Heilongjiang, which contains 10.25% molybdenum, 5.12% copper, and 2.13% lead. It also contains a certain amount of pyrite and gangues such as quartz, chalcedony and mica. Coarse concentrate weight is 100 grams.

[0031] The inhibitor is prepared from thioglycolic acid, sodium silicate and glucuronic acid as raw materials, and the weight ratio of the three is 40:500:1. Dissolve the three in water according to this ratio to make an aqueous solution with a weight concentration of 5%.

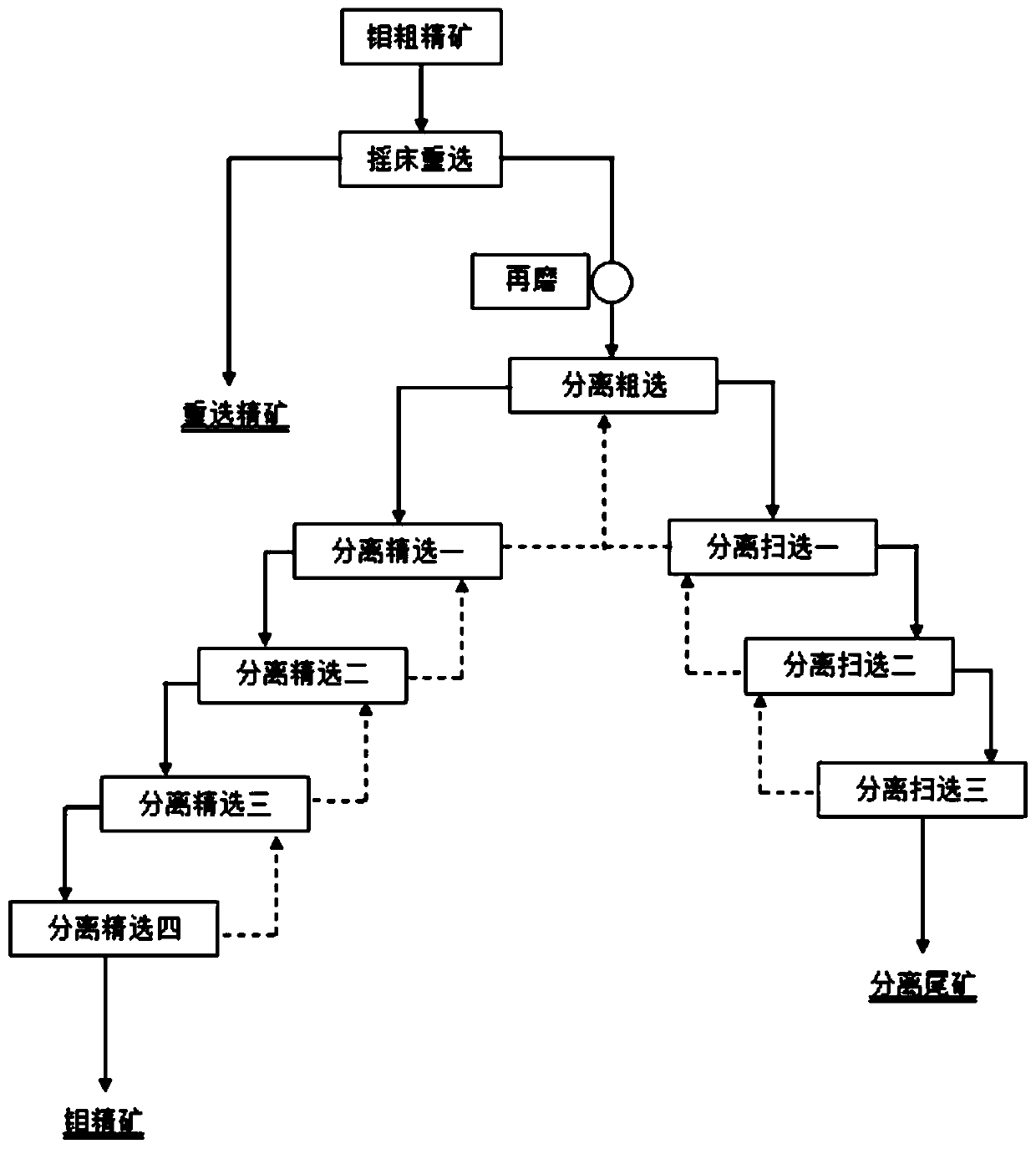

[0032] Such as figure 1 As shown, the present embodiment provides a method for purifying molybdenum rough concentrate, which specifically includes the following steps:

[0033] (1) Gravity separation: Use a fine-grained shaking table to carry out shaking table gravity separation of molybdenum coarse concentrate to obtain gravity separation concentrate and gravity separation tailings products mainly composed of lead impurities; The shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com