Molybdenum diselenide gas-sensitive sensing material as well as preparation and application thereof

A technology of molybdenum diselenide and gas-sensing materials, applied in the field of molybdenum diselenide nano-materials and its preparation, application, molybdenum diselenide gas-sensing sensing materials and its preparation, which can solve the problem of reserve limitation, widely used, accelerated sensors Electronic exchange with the test gas, etc., to achieve the effect of industrialization, high selectivity and stability, and enhanced chemical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a preparation method of molybdenum diselenide nanometer material, comprising the following steps:

[0075] A) After mixing molybdenum acetylacetonate and oleylamine, solution A is obtained;

[0076] After mixing dibenzyl diselenide and oleylamine, solution B is obtained;

[0077] B) After mixing the solution A and solution B obtained in the above steps again, and reacting under a protective atmosphere, the molybdenum diselenide nanomaterial is obtained.

[0078] In the present invention, the structure, selection and appearance of the product or raw material in the preparation method of the molybdenum diselenide nanomaterial, and its optimization principles, preferably the structure of the product or raw material corresponding to the aforementioned molybdenum diselenide nanomaterial , selection and shape, and their optimization principles may correspond to each other, and will not be repeated here.

[0079]In the present invention, s...

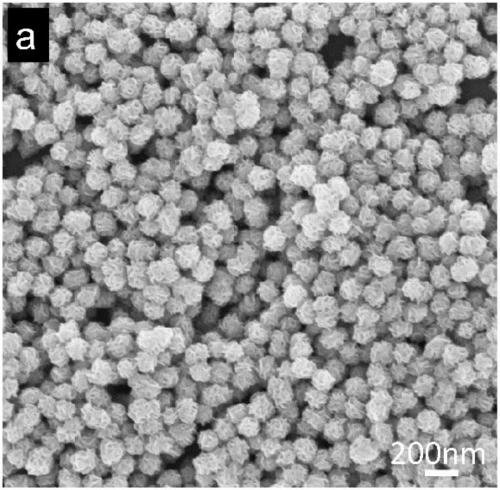

Embodiment 1

[0108] Weigh 0.6520g (2mmol) molybdenum acetylacetonate [MoO 2 (acac) 2 ] was dissolved in oleylamine with a volume of 10mL, and after ultrasonic treatment for 15 minutes to dissolve completely, it was marked as material liquid A; another 0.6800g (2mmol) dibenzyl diselenide [(PhCH 2 ) 2 Se 2 ], was dissolved in oleylamine with a volume of 10 mL, and was marked as material solution B after ultrasonic treatment for 15 minutes to completely dissolve.

[0109] Mix the above materials A and B, and carefully transfer them to the bottom of a 50mL three-neck flask, add a high-temperature magnet to stir, then pass in argon for 20 minutes to exhaust the air, and heat the reactant to 130°C for 30 minutes to remove moisture and Other low-boiling impurities. Through temperature programming, the temperature was raised to 240° C. at a rate of 10° C. per minute and reacted for 20 minutes. After the reaction was completed, it was naturally cooled to room temperature, and the product obtai...

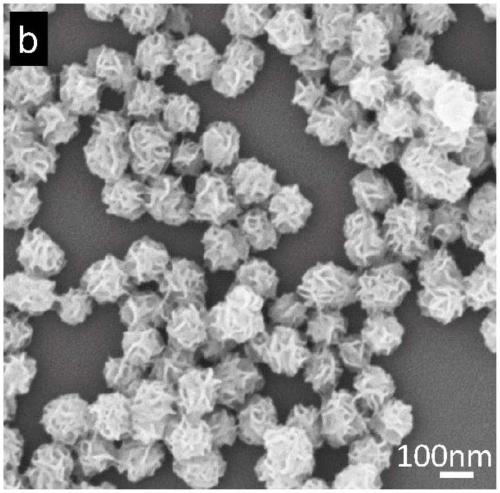

Embodiment 2

[0134] Weigh 1.3040g (4mmol) molybdenum acetylacetonate [MoO 2 (acac) 2 ] was dissolved in oleylamine with a volume of 15mL, and after ultrasonic treatment for 18 minutes to dissolve completely, it was marked as material liquid A; another 1.3600g (4mmol) dibenzyl diselenide [(PhCH 2 ) 2 Se 2 ], dissolved in oleylamine with a volume of 15mL, and after ultrasonic treatment for 18 minutes to completely dissolve, it was marked as material solution B.

[0135] Mix the above materials A and B, and carefully transfer them to the bottom of an 80mL three-necked flask, add a high-temperature magnet to stir, then pass in argon for 25 minutes to exhaust the air, and heat the reactant to 140°C for 40 minutes to remove moisture and Other low-boiling impurities. Through temperature programming, the temperature was raised to 245° C. at a rate of 12° C. per minute and reacted for 25 minutes. After the reaction was completed, it was naturally cooled to room temperature, and the product obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com