Starch-modified sodium alkyl benzene sulfonate derivative and application thereof

A sodium alkylbenzene sulfonate and starch modification technology, which is applied to medical preparations containing active ingredients, cosmetic preparations, skin care preparations, etc., can solve the problem of unsatisfactory data, meager profit growth, and high costs and other problems, to achieve the effect of economical and simple preparation process, broad application prospects, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

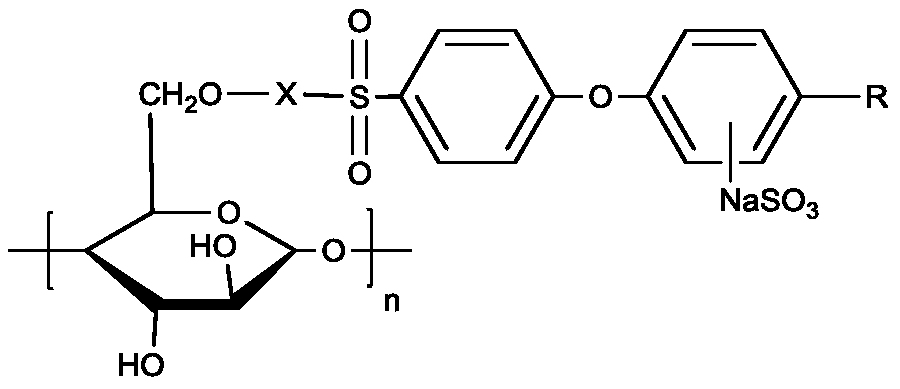

[0028] A starch-modified sodium alkylbenzenesulfonate derivative having the following structure:

[0029]

[0030] Among them, the reaction mechanism is as follows:

[0031]

[0032] This reaction is essentially the reaction of sodium sulfonate with hydroxyl groups on starch. The raw material alkyl diphenyl ether disulfonate sodium derivative has two sodium sulfonate groups. Due to the steric effect, the hydroxyl group on the starch will preferentially react with the para-position sodium alkylbenzene sulfonate to generate the above product . Therefore it is very important to strictly control the amount of reactant starch and alkyl diphenyl ether sodium sulfonate derivatives. Usually, the excess of starch should not exceed 20%, so as to avoid the excessive hydroxyl and alkyl diphenyl brought in the starch. The sodium sulfonate in the ortho or para position in the ether disulfonate derivative reacts again, and the generated by-product does not have the function of surfac...

Embodiment 2

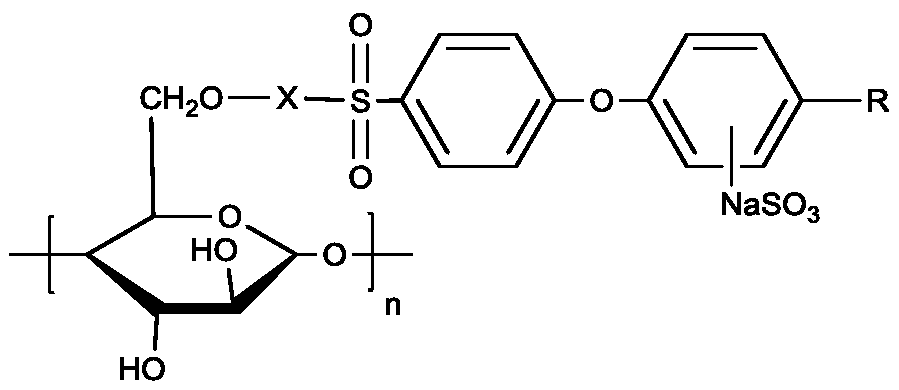

[0036] A starch-modified sodium alkylbenzenesulfonate derivative having the following structure:

[0037]

[0038] Among them, the reaction mechanism is as follows:

[0039]

[0040] The steps of its preparation method are:

[0041] Mix the derivatives of sodium alkyl diphenyl ether disulfonate and starch at a ratio of 1:1.2, use 20 wt% potassium hydroxide solution as a catalyst, and add 1 wt% of the starch. Then react at 120°C for 5h, and then dry at high temperature to obtain the product. Yield = 88%, purity 93%.

Embodiment 3

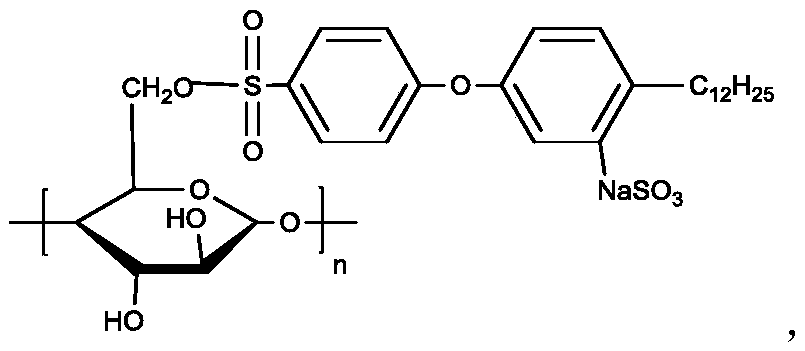

[0043] A starch-modified sodium alkylbenzenesulfonate derivative having the following structure:

[0044]

[0045] Among them, the reaction mechanism is as follows:

[0046]

[0047] The steps of its preparation method are:

[0048] Mix the derivatives of sodium alkyl diphenyl ether disulfonate and starch at a ratio of 1:1.1, use 10wt% sodium carbonate solution as a catalyst, and add 0.5wt% of the starch. Then react at 100°C for 4h, and then dry at high temperature to obtain the product. Yield = 84%, purity 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com