Catalyst for catalytically removing nitrogen oxides at low temperature and preparation method thereof

A technology for low-temperature catalysis and nitrogen oxides, applied in the field of low-temperature catalytic removal of nitrogen oxides in diesel engine exhaust and its preparation, low-temperature catalytic removal of nitrogen oxides and its preparation, can solve the problems affecting catalyst activity and stability, Problems such as poor catalytic activity and selectivity, low catalytic activity of molecular sieves, etc., to achieve stable and excellent low-temperature SCR performance, low price, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

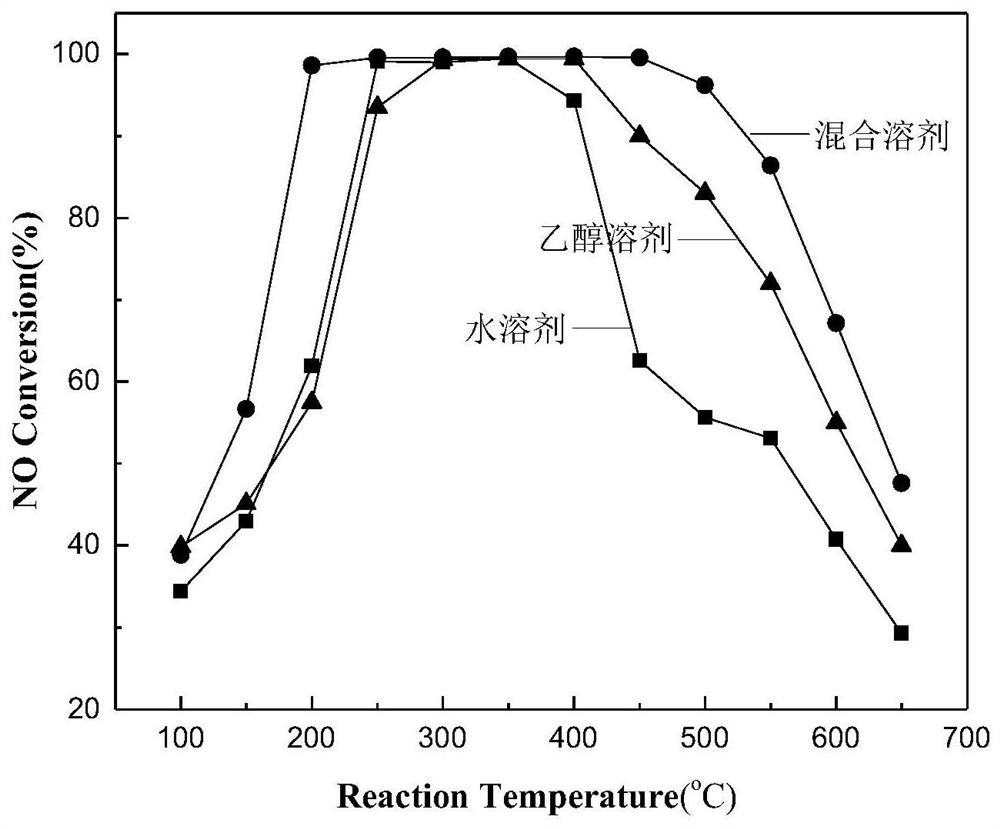

[0049] This embodiment relates to the influence of different solvents on the SCR activity of iron / beta zeolite catalysts when oxalic acid is added as organic matter, and its preparation method includes the following steps:

[0050] 1. Ferric acetate is used as the iron source, oxalic acid is used as the organic compound, and the molar ratio of the iron element in the organic compound to the iron source is 1:1. The comparison uses water or ethanol or a mixture of both as solvent.

[0051] 2. The different sample solutions were evaporated to dryness with stirring at 90°C, and dried in an oven at 110°C for 12 hours.

[0052] 3. Put the powdered solid sample into a corundum crucible with a volume of 200mL, then place the sample-filled crucible in a muffle furnace, raise the temperature to 550°C at a rate of 5°C / min, and keep it warm for 4h. After cooling, take it out and grind it in an agate mortar to obtain the target product. In the prepared catalyst, the mass percent content ...

Embodiment 2

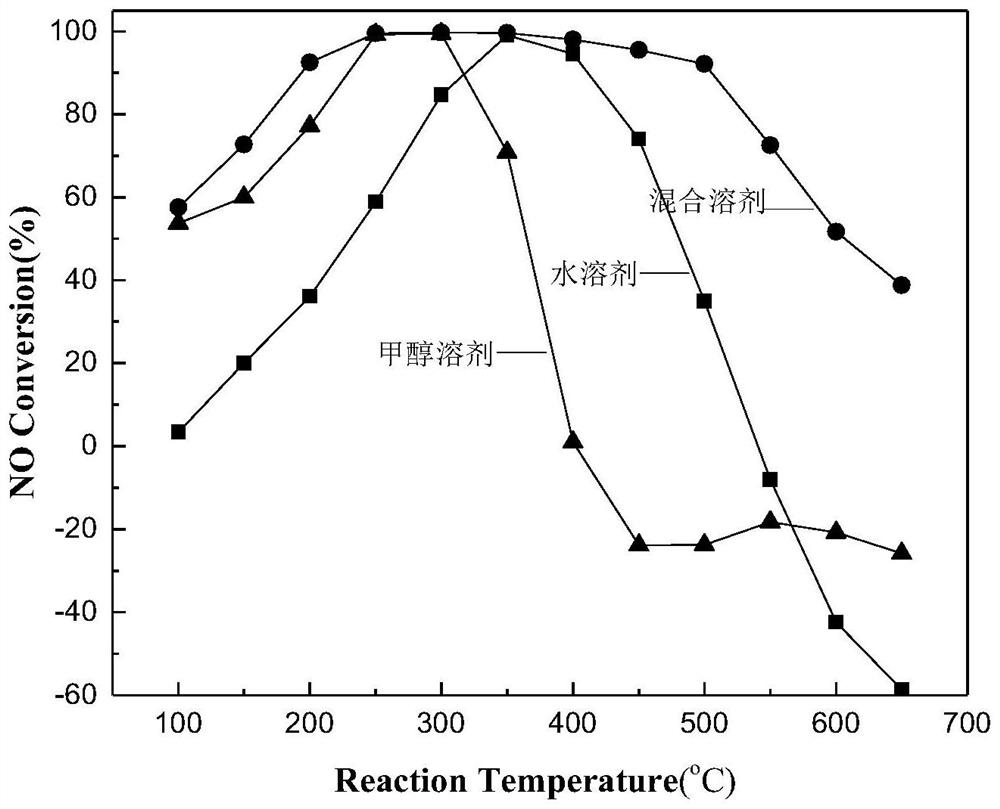

[0057] This embodiment relates to the influence of different solvents on the SCR activity of iron-based MFI molecular sieve catalysts when citric acid is added as organic matter, and its preparation method includes the following steps:

[0058] 1. Ferric acetate is used as the iron source, citric acid is used as the organic compound, and the molar ratio of the iron element in the organic compound to the iron source is 9: 1, and water or methanol or a mixture of the two is used as a solvent for comparison.

[0059] 2. The different sample solutions were evaporated to dryness with stirring at 90°C, and dried in an oven at 110°C for 12 hours.

[0060] 3. Put the powdered solid sample into a corundum crucible with a volume of 200mL, then place the sample-filled crucible in a muffle furnace, raise the temperature to 550°C at a rate of 5°C / min, and keep it warm for 4h. After cooling, take it out and grind it in an agate mortar to obtain the target product. In the prepared catalyst,...

Embodiment 3

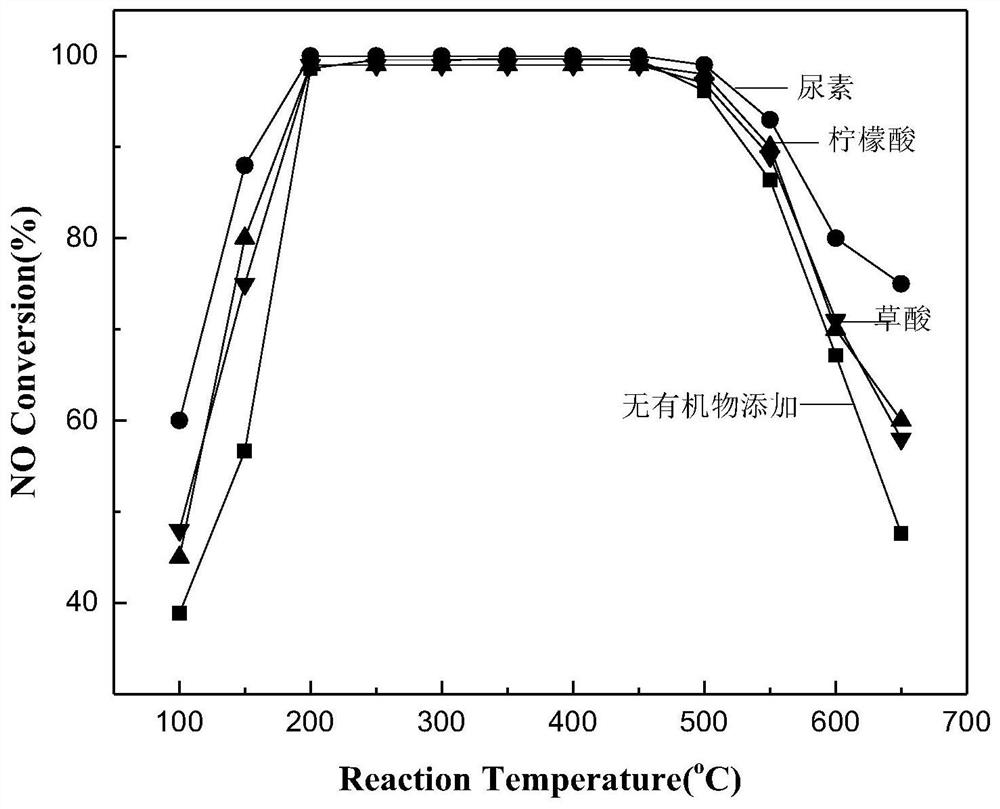

[0065] This embodiment relates to the influence of different organic matter additions on the SCR activity of the iron / beta zeolite catalyst, and its preparation method comprises the following steps:

[0066] 1. Using ferric nitrate as the iron source, compared to using a mixture of water and ethanol as the solvent.

[0067] 2. Add oxalic acid or citric acid or urea with 5 times molar ratio of iron to the above solution, stir and disperse, stir and evaporate different sample solutions at 90°C, and dry them in an oven at 110°C for 12h.

[0068] 3. Put the powdered solid sample into a corundum crucible with a volume of 200mL, then place the sample-filled crucible in a muffle furnace, raise the temperature to 550°C at a rate of 5°C / min, and keep it warm for 4h. After cooling, take it out and grind it in an agate mortar to obtain the target product. In the prepared catalyst, the mass percent content of iron was 5%.

[0069] 4. Extruding, crushing and sieving the obtained differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com