A kind of stable zeaxanthin and preparation method thereof

A zeaxanthin stabilization technology, applied in the field of zeaxanthin, can solve problems such as low yield and insufficient stability of zeaxanthin, achieve high yield, overcome solvent residues, and extend the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

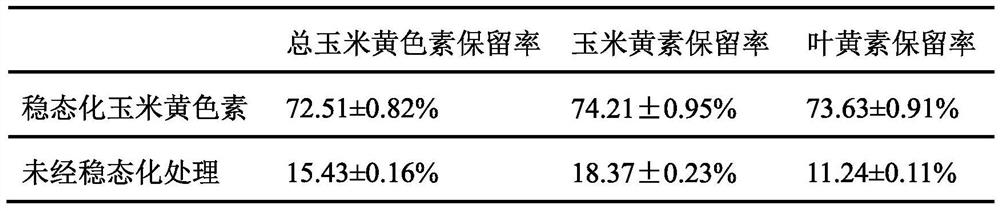

Embodiment 1

[0039] A preparation method for stable zeaxanthin, comprising the following steps:

[0040] (1) Using corn yellow powder, a by-product of corn starch production, as raw material, wash the corn yellow powder twice with flowing purified water to wash away the starch granules mixed in it; after cleaning, put it in an oven and dry it moderately at 42°C until the corn The water content in the yellow powder is kept at 16%, that is, the corn yellow powder with moderate water content after washing away the starch granules is obtained.

[0041] Put the corn yellow powder obtained through the above treatment in a steam explosion machine, and use saturated water vapor for explosion treatment, adjust the steam explosion pressure to 1.22Mpa, and maintain the pressure for 48s. After the treatment time is reached, the material is decompressed instantly to complete Explosion to obtain maize yellow powder with loose structure pretreated by steam explosion.

[0042] The above-mentioned corn ye...

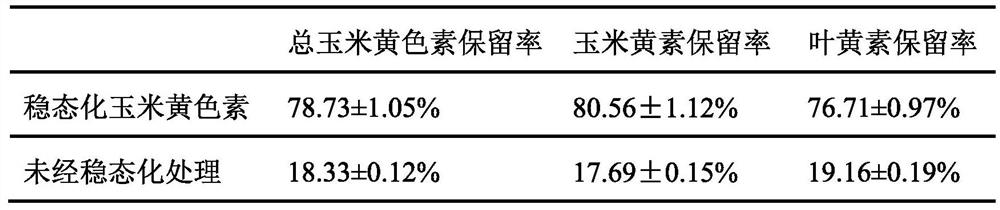

Embodiment 2

[0047] A preparation method for stable zeaxanthin, comprising the following steps:

[0048] (1) Use corn yellow powder, a by-product of corn starch production, as raw material, wash corn yellow powder with flowing purified water 3 times, and wash away the starch granules mixed in it; after cleaning, put it in an oven and dry it moderately at 45°C until the corn The water content in the yellow powder is kept at 17%, that is, the corn yellow powder with starch granules washed out and moderate water content is obtained.

[0049] Put the corn yellow powder obtained through the above treatment in a steam explosion machine, use saturated water vapor for explosion treatment, adjust the steam explosion pressure to 1.30Mpa, and maintain the pressure for 40s. After the treatment time is reached, the material is decompressed instantly to complete Explosion to obtain maize yellow powder with loose structure pretreated by steam explosion.

[0050] The above-mentioned maize yellow powder t...

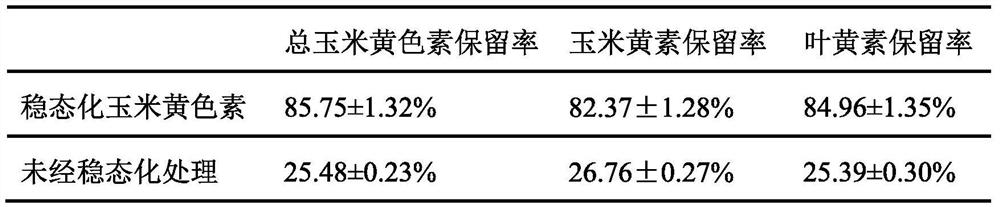

Embodiment 3

[0055] A preparation method for stable zeaxanthin, comprising the following steps:

[0056] (1) Use corn yellow powder, a by-product of corn starch production, as raw material, wash the corn yellow powder 2 to 3 times with flowing purified water, and wash away the starch granules mixed therein; after cleaning, place it in an oven and dry it moderately at 41°C, Until the moisture content in the corn yellow powder is maintained at 15%, the corn yellow powder with the starch granules washed out and moderate water content is obtained.

[0057] Put the corn yellow powder obtained through the above treatment in a steam explosion machine, use saturated water vapor for explosion treatment, adjust the steam explosion pressure to 1.25Mpa, and maintain the pressure for 45s. After the treatment time is reached, the material is decompressed instantly to complete Explosion to obtain maize yellow powder with loose structure pretreated by steam explosion.

[0058] The above-mentioned corn ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com