A kind of preparation method of composite ultrafiltration membrane containing polyelectrolyte

An electrolyte and ultrafiltration membrane technology, applied in the field of separation membranes, can solve the problems of complex processes, failure to meet industrial processing requirements, low mechanical strength of porous membranes, etc., and achieve the effect of no agglomeration, large industrialization potential, and high retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

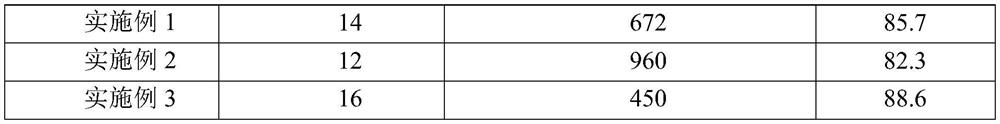

Embodiment 1

[0016] The present embodiment provides a polyacrylic acid modified with dopamine (DA) as the polyanionic electrolyte (PAA-DA), Tf 2 N - Quaternized chitosan as counter ion as polycation electrolyte (QCS-Tf 2 N), the organic solvent is dimethyl sulfoxide (DMSO), and the polymer is polysulfone to prepare a composite ultrafiltration membrane, which is prepared according to the following steps:

[0017] 0.035g (1% relative to the mass of polysulfone) of PAA-DA (PAA molecular weight is 100K Da) and 0.035g (1% relative to the mass of polysulfone) QCS-Tf 2 N was added to 5mL of DMSO solution, stirred and sonicated for 10min to completely dissolve, then this solution was added to 3.5g of polysulfone and 15.5mL of DMSO polymer solution, stirred and sonicated to obtain a uniform casting solution . Scrape the membrane on a glass plate with 2mL of the casting solution, and immerse it in a gel water bath at 30°C for simultaneous phase inversion to obtain a polyelectrolyte-containing com...

Embodiment 2

[0019] The difference from Example 1 is that the mass fraction of the polysulfone solution is 12%.

Embodiment 3

[0021] The difference from Example 1 is that the mass fraction of the polysulfone solution is 16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com