Flexible composite laminated solar cell and preparation method thereof

A solar cell and composite stack technology, applied in the field of solar energy, can solve the problems that gallium arsenide and perovskite cells are not effectively combined, the conversion efficiency is not greatly improved, and the size of the cell composition is large, so as to improve the combined synergy effect, The effect of various preparation methods and reduction of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

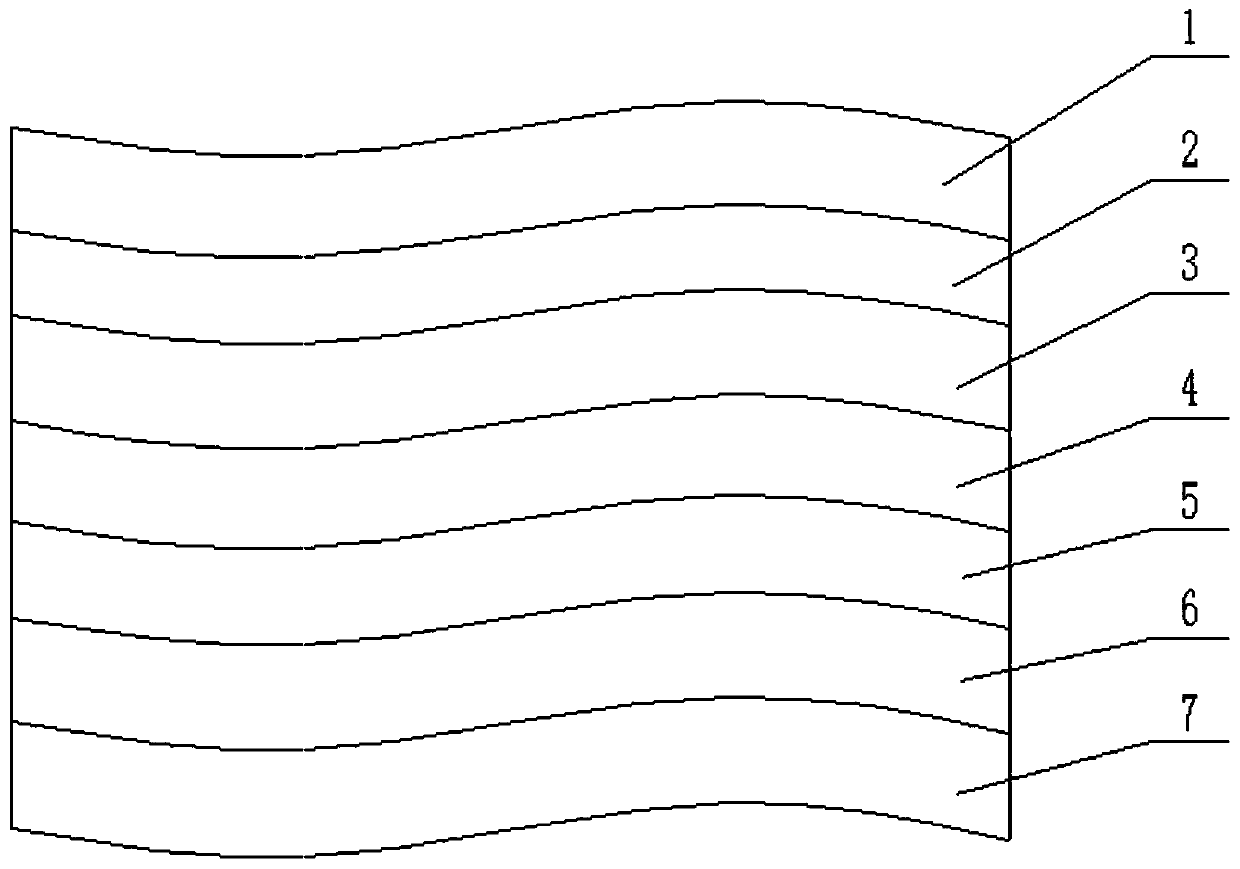

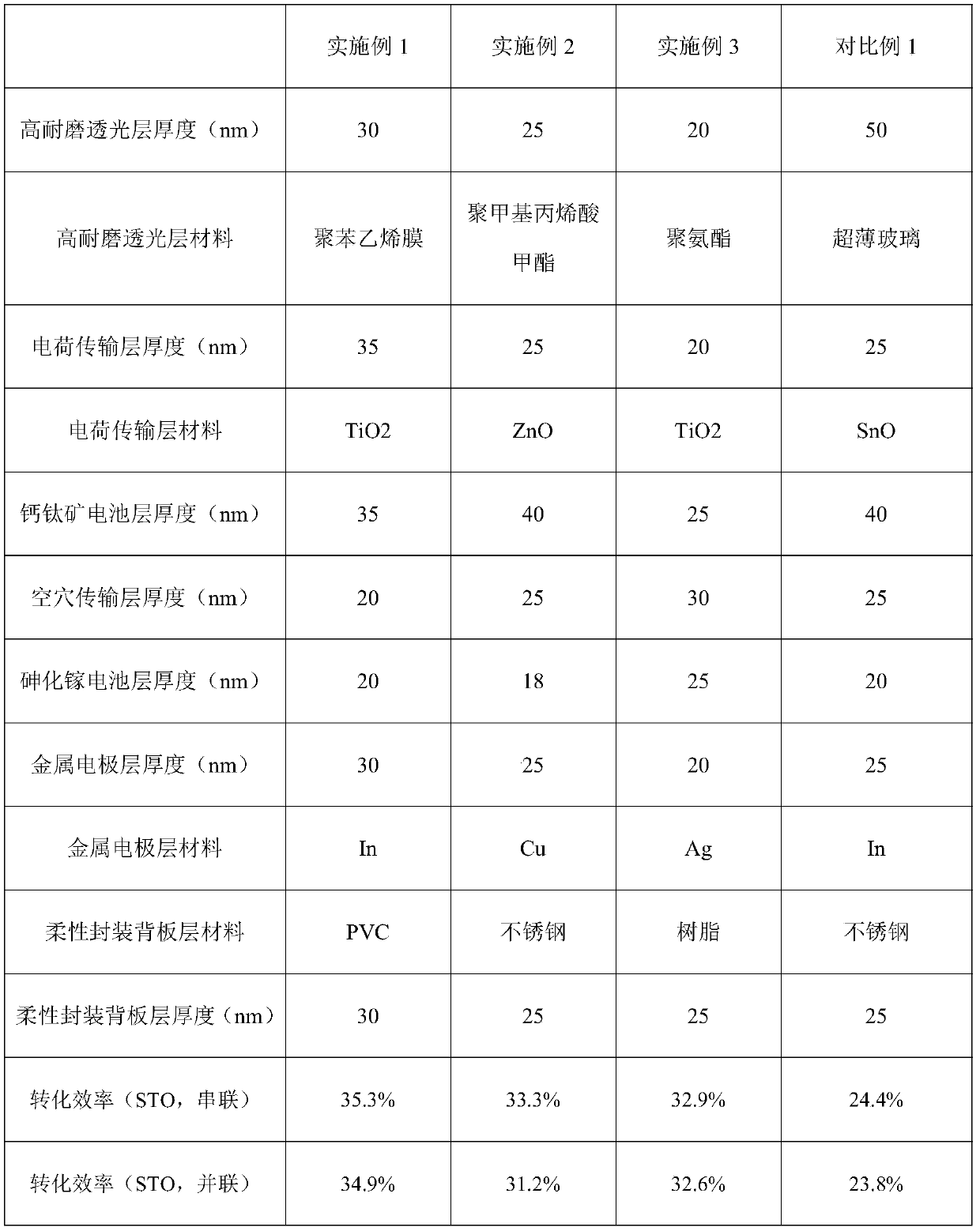

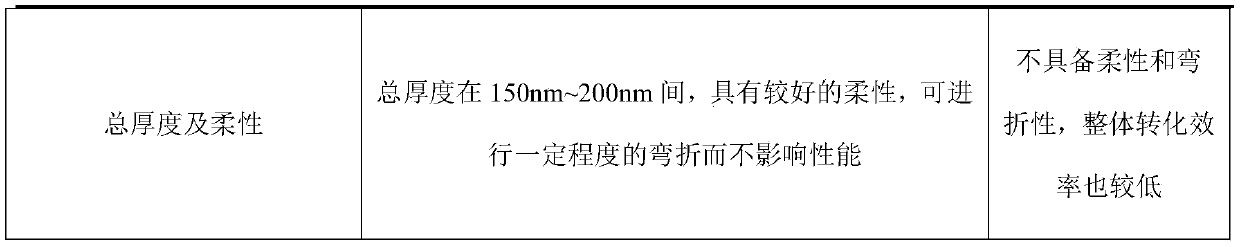

[0031] Such as figure 1 As shown, a flexible composite stacked solar cell, from the light-receiving surface to the backlight surface, is a high wear-resistant light-transmitting layer 1, a charge transport layer 2, a perovskite cell layer 3, a hole transport layer 4, and gallium arsenide Battery layer 5 , metal electrode layer 6 and flexible packaging backplane layer 7 .

[0032] Specifically, the high wear-resistant light-transmitting layer is a flexible transparent material with certain wear resistance, and the high wear-resistant light-transmitting layer can preferably be polymethyl methacrylate, polystyrene, polyurethane, acrylate and polycarbonate One or more of them are not limited to the above materials. The charge transport layer is a transparent conductive layer with electron transport effect, and the material of the charge transport layer is preferably one or more mixtures of ZnO, SnO and TiO2. The perovskite battery layer is a material of ABX3 structure, A and B a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com