Antibacterial hydrogel and preparation method and application thereof

A hydrogel, deionized water technology, applied in capsule delivery, pharmaceutical formulation, pharmaceutical science, etc., can solve the problems of easy killing of normal cells, high cytotoxicity, fast release, etc., and achieve excellent biocompatibility and mechanical properties. Good performance and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

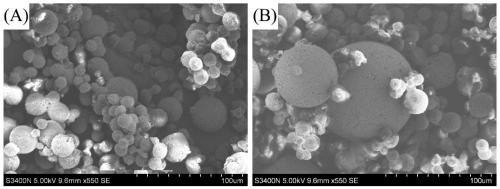

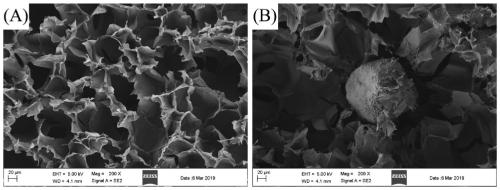

[0038]Preparation of sodium alginate microspheres (Alg): configure 20 mL of 2 wt % sodium alginate aqueous solution, stir well and set aside. Add the above-mentioned sodium alginate aqueous solution into a flask containing 100 mL of soybean oil, stir with a mechanical stirrer at a speed of 400 to 600 r / min (500 r / min in this example) for 1 h at 60 ° C, and then add 1 mL of Span 80 After emulsifying at a speed of 400-600r / min (500r / min in this embodiment) for 60min, add 40mL of calcium chloride solution with a concentration of 2%, and continue to stir for 60min. Then add 10 mL of isopropanone at 4° C., stir for 30 minutes, and then centrifuge at 4000 to 8000 r / min for 5 to 10 minutes at 25° C. (6000 r / min for 10 minutes in this example). Finally, it was alternately washed three times with isopropanol, ethanol and deionized water to remove the oil phase, and finally freeze-dried to obtain the sodium alginate microspheres (Alg).

Embodiment 2

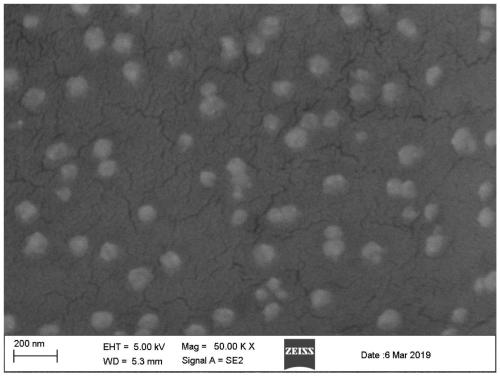

[0040] Preparation of silver nanoparticles (AgNPs): (1) Dissolve 500 mg of silver nitrate in 20 mL of ethanol to obtain a dispersion, and store in the dark; (2) Dissolve 1 g of polyvinylpyrrolidone (PVP) in 20 mL of ethanol to obtain a For the original solution, place the reducing solution in a constant temperature water bath at 60°C to keep warm for later use; (3) Add the dispersion liquid to the reducing solution in the constant temperature water bath in the dark, and keep stirring the reducing solution during the addition. Along with the progress of the reaction, it can be observed that the color of the reaction solution gradually changes from colorless and transparent to golden yellow, and continues to deepen, and finally becomes dark red until the color becomes stable, and freeze-dried to obtain the silver nanometer (AgNPs ).

Embodiment 3

[0042] Preparation of sodium alginate microspheres loaded with silver nanoparticles (Alg@AgNPs): (1) 500 mg of silver nitrate was dissolved in 20 mL of ethanol to obtain a dispersion, and stored in the dark; (2) 1 g of polyvinylpyrrolidone (PVP) Dissolve in 20mL of ethanol to obtain a reducing solution, and place the reducing solution in a constant temperature water bath at 60°C to keep warm for later use; (3) In the dark, add 1.5g of sodium alginate microspheres prepared by the method in Example 1 to disperse (4) After centrifuging the reaction system of step (3), wash it with deionized water, and then centrifuge after ultrasonic vibration; repeat the operation 5 times; (5) disperse the reaction product in ethanol, and then Drop into the reducing solution in a constant temperature water bath, and stir the reducing solution continuously during the addition process. Along with the progress of the reaction, it can be observed that the color of the reaction solution gradually cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com