Preparation method of water-based cement elastic emulsion-based flexible facing plate substrate

An elastic emulsion, base-flexible technology, applied in construction, building structure, covering/lining, etc., can solve the problems of distortion, high cost, long-term engineering application test and other problems of decorative panels, and achieves water-based environmental protection and smooth surface. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a water-based cement elastic emulsion-based flexible decorative panel substrate is characterized in that it comprises the following steps:

[0033] a. The ratio of water-based cement elastic emulsion-based flexible decorative panel substrate is:

[0034] The components and mass percentage content of the substrate include: 15% of 425 cement, 5% of F-class fly ash, 3% of high-alumina cement, 3% of semi-hydrated natural gypsum, 30% of 40-mesh sand, 15% % water-based elastic emulsion, 28.3% water, 0.2% water reducer, 0.2% hydroxypropyl cellulose ether, 0.2% dispersant, 0.1% defoamer;

[0035] B, the preparation method of this substrate is:

[0036] The first step is to prepare dry powder: mix cement, fly ash, high alumina cement, gypsum, and sand evenly through dry mixing;

[0037] The second step is to prepare wet material: add water-based elastic emulsion, water reducer, hydroxypropyl cellulose ether, and dispersant to water to disperse evenly;

[...

Embodiment 2-10

[0044] Mainly change the percentage content of cement and water-based elastic emulsion in the batching, change the percentage content of sand and water simultaneously, other raw materials and percentage are the same as embodiment 1, relevant parameter changes are as shown in table 1:

[0045] Table 1:

[0046] Example number cement(%) Water-based elastic emulsion (%) sand(%) water(%) 2 10 10 35 33.4 3 10 20 35 23.4 4 10 30 30 18.4 5 20 10 25 33.4 6 20 20 25 23.4 7 20 30 20 18.4 8 30 10 15 33.4 9 30 20 15 23.4 10 30 30 10 18.4

[0047] In embodiment 2-10, along with cement rises, the decline of water-based elastic emulsion, flexibility increases, but tensile strength reduces, but all can reach the requirement greater than 0.30MPa, under the situation that flexibility reaches the requirement, tensile strength is bigger and more Conducive to construction performance, conducive to flat wal...

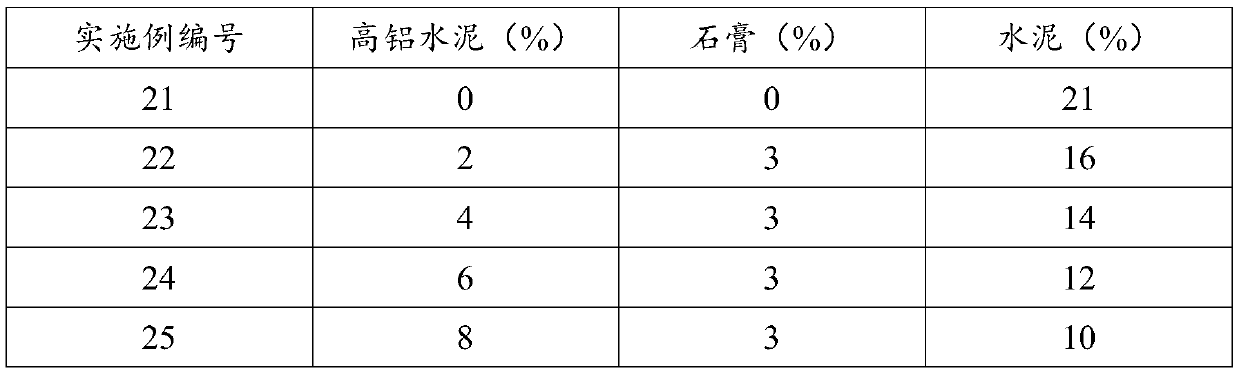

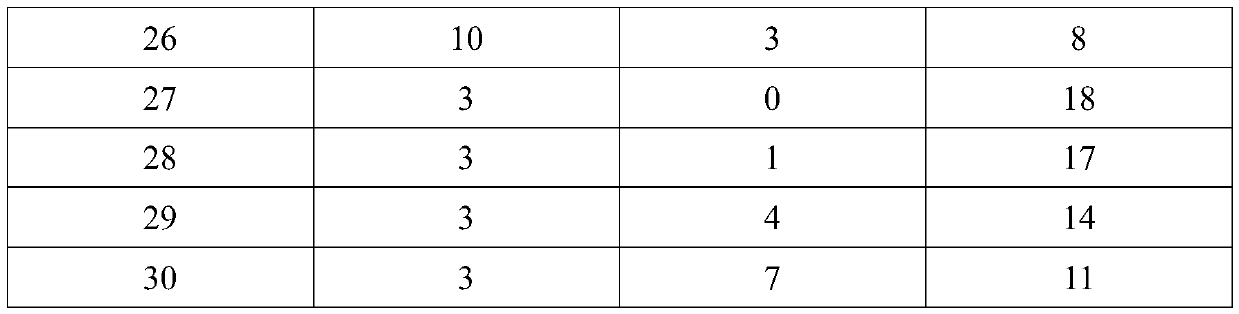

Embodiment 11-20

[0049] Mainly change the percentage content of fly ash in the batching, change the percentage content of sand simultaneously, other raw materials and raw material percentage are the same as embodiment 1, relevant parameter changes are as shown in table 2:

[0050] Table 2:

[0051] Example number Fly ash (%) sand(%) 11 0 35 12 1 34 13 2 33 14 3 32 15 4 31 16 6 29 17 7 28 18 8 27 19 9 26 20 10 25

[0052] In Examples 11-20, as the content of fly ash increases, the density of the board decreases, which can improve the lightness of the board, but it will increase the water consumption and prolong the drying time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com