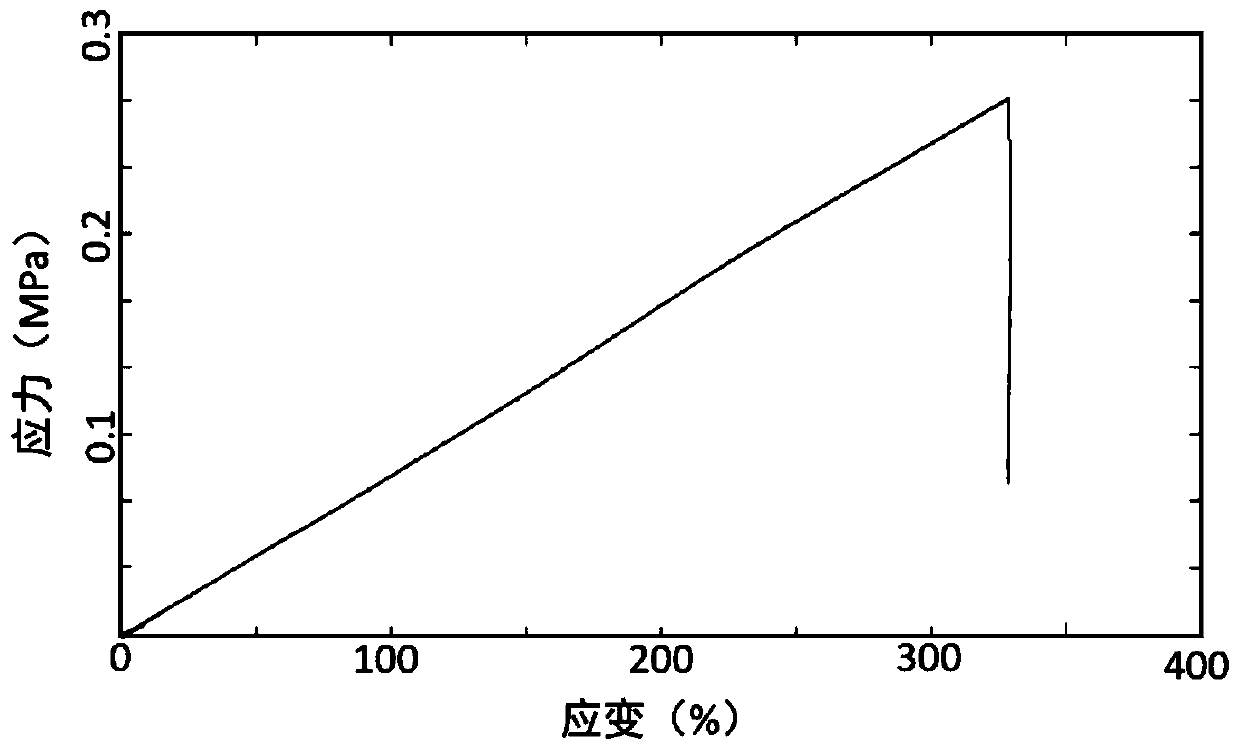

Polyvinyl alcohol sponge with high elongation and preparation method thereof

A polyvinyl alcohol sponge and polyvinyl alcohol technology, applied in the field of polymer materials, can solve the problems of high consumption, waste of resources and environment, difficult interaction of reactants, etc., and achieve less waste of resources, good environmental protection, and good controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

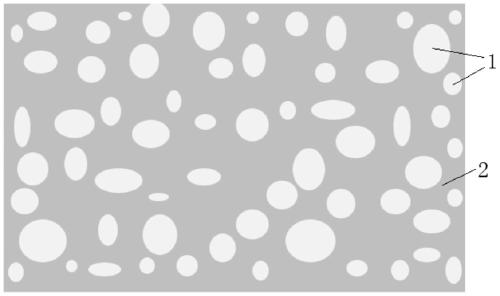

[0023] The invention provides a kind of preparation method (abbreviation method) of polyvinyl alcohol sponge with high elongation, it is characterized in that the method comprises the following steps:

[0024] (1) After mixing polyvinyl alcohol (PVA), cellulose, carbonate and deionized water, stir magnetically at a temperature of 80-100°C for 1-2 hours under closed conditions until the dissolution is complete, and a uniform milky white polyethylene is obtained Alcoholic solution;

[0025] In step 1), the sealing condition is to adopt tin foil or plastic wrap to seal the container to prevent moisture from evaporating.

[0026] In step 1), the carbonate includes calcium carbonate, potassium carbonate or sodium carbonate etc. (preferably calcium carbonate).

[0027] In step 1), the cellulose is bacterial cellulose (BC); the mass ratio of polyvinyl alcohol, bacterial cellulose, carbonate to deionized water is 42-46:2-4:8-12:240- 260 (preferably 45:6:10:250); the molecular weight...

Embodiment 1

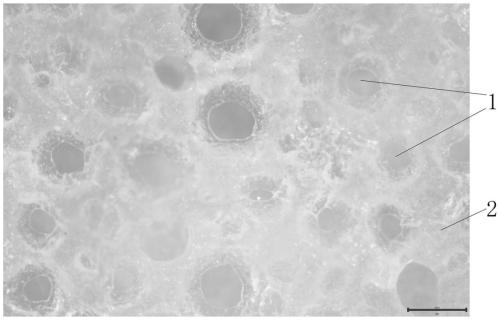

[0042] (1) Put 10g of polyvinyl alcohol (molecular weight: 145000), 0.6g of bacterial cellulose, 3g of calcium carbonate and 100ml of deionized water in a beaker, place a stirring bar of appropriate size, then seal it with tin foil, and stir it magnetically at 95°C Stir and dissolve in a water bath for 1.5 hours to obtain a uniform milky white polyvinyl alcohol solution;

[0043](2) Cool down the polyvinyl alcohol solution to 76°C, pour the mixed 10ml emulsifier OP-10 and 14ml dimethyl carbonate into the beaker containing the polyvinyl alcohol solution at one time, and stir for 2 hours until the solution reacts as White and sticky, take out the magnetic stirrer;

[0044] (3) Cool the white viscous solution to 36°C, add 12ml of foaming agent n-pentane, and use a strong mixer to stir at a speed of 1500r / min until bubbles of uniform size are generated in the solution to obtain a foamed solution;

[0045] (4) Pour the foamed solution into the mold, and freeze-thaw repeatedly 3 ti...

Embodiment 2

[0064] (1) Put 10g of polyvinyl alcohol (molecular weight: 145000), 0.6g of bacterial cellulose, 3g of calcium carbonate and 110ml of deionized water in a beaker, place a stirring bar of appropriate size, then seal it with tin foil, and stir it magnetically at 95°C Stir and dissolve in a water bath for 1.5 hours to obtain a uniform milky white polyvinyl alcohol solution;

[0065] (2) Cool down the polyvinyl alcohol solution to 76°C, pour the mixed 10ml emulsifier OP-10 and 14ml dimethyl carbonate into the beaker containing the polyvinyl alcohol solution at one time, and stir for 2 hours until the solution reacts as White and sticky, take out the magnetic stirrer;

[0066] (3) Cool the white viscous solution to 36°C, add 12ml of foaming agent n-pentane, and use a strong mixer to stir at a speed of 1500r / min until bubbles of uniform size are generated in the solution to obtain a foamed solution;

[0067] (4) Pour the foamed solution into the mold, and freeze and thaw repeatedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com