Sulfur-nitrogen co-doped graphene modified graphite felt composite electrode and preparation method thereof

A composite electrode and graphene technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of complex preparation methods, low catalytic performance, low doping content, etc., and achieve good doping effect, large surface area, sulfur Effect of Nitrogen Doping Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

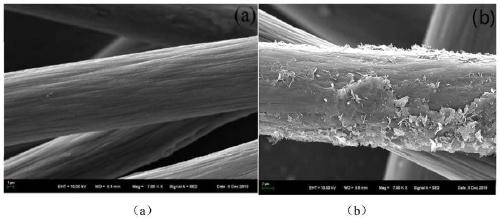

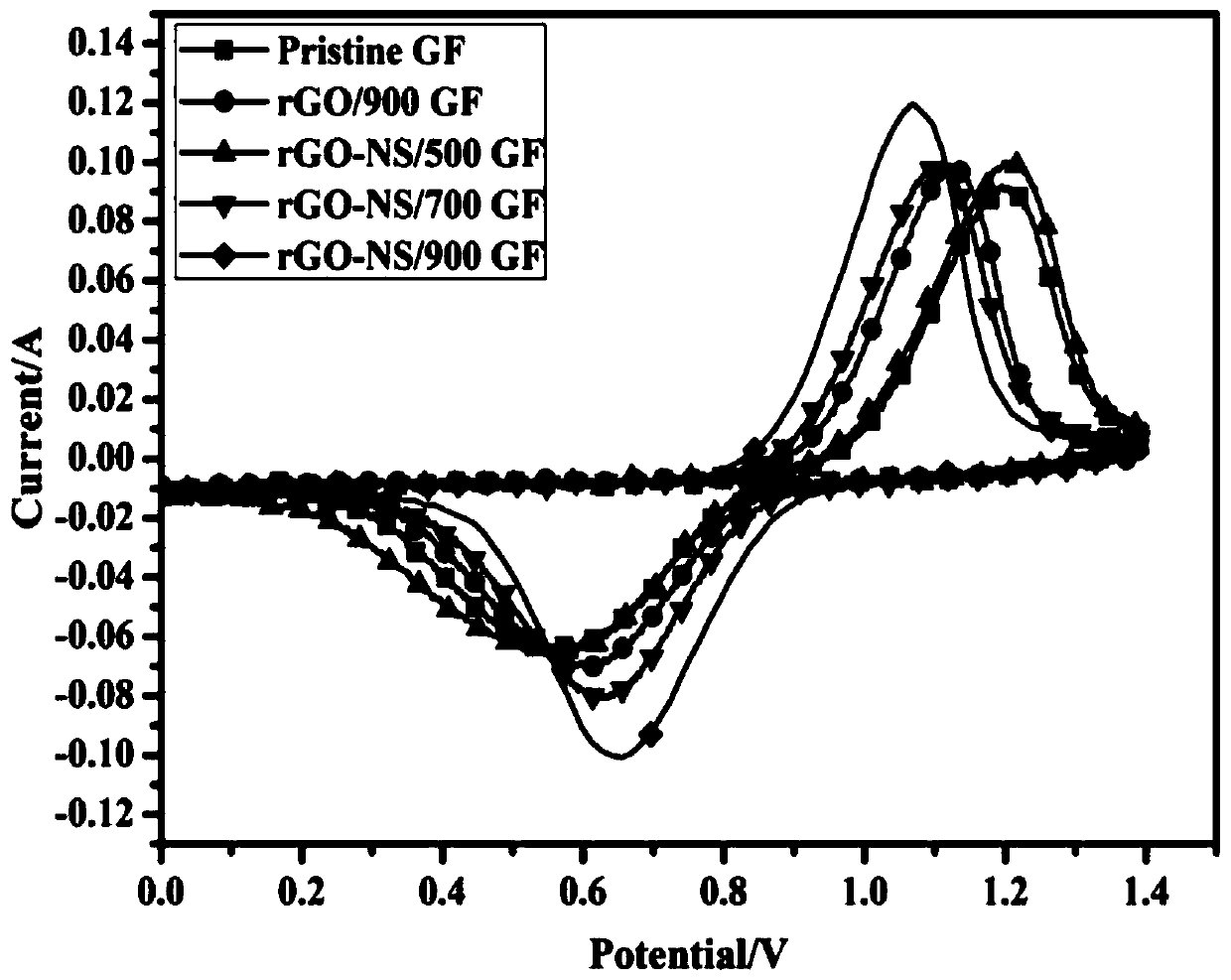

[0041] A sulfur and nitrogen co-doped graphene-modified graphite felt composite electrode and a preparation method thereof, the steps of the preparation method are as follows:

[0042] s1. Add graphene oxide into deionized water to prepare a 2 mg / ml solution, ultrasonically oscillate and disperse, and then perform magnetic stirring. During the stirring process, add thiourea and L-ascorbic acid respectively to obtain a mixed solution, wherein the mass ratio of thiourea to graphene oxide is 10:1, the mass ratio of L-ascorbic acid and graphene oxide is 5:1, then drip ammonia water to adjust the pH of the mixed solution to pH=8, and continue to stir to obtain a uniform and stable suspension;

[0043] s2. Transfer the suspension to the reaction kettle, seal it and put it in a constant temperature drying oven, heat it at 180°C for 12 hours, take it out after natural cooling, vacuum filter the suspension in the reaction kettle, and then use ethanol and remove Washing with ionic water...

Embodiment 2

[0047] A sulfur and nitrogen co-doped graphene-modified graphite felt composite electrode and a preparation method thereof, the steps of the preparation method are as follows:

[0048] s1. Add graphene oxide into deionized water to form a 2mg / ml solution, ultrasonically oscillate and disperse, and then perform magnetic stirring. During the stirring process, add thiourea and L-ascorbic acid respectively to obtain a mixed solution, in which the mass of thiourea and graphene oxide The ratio is 10:1, the mass ratio of L-ascorbic acid to graphene oxide is 5:1, then drip ammonia water to adjust the pH of the mixed solution to pH=8, and continue to stir to obtain a uniform and stable suspension;

[0049] s2. Transfer the suspension to the reaction kettle, seal it and put it in a constant temperature drying oven, heat it at 180°C for 12 hours, take it out after natural cooling, vacuum filter the suspension in the reaction kettle, and then use ethanol and remove Washing with ionic wate...

Embodiment 3

[0053] A sulfur and nitrogen co-doped graphene-modified graphite felt composite electrode and a preparation method thereof, the steps of the preparation method are as follows:

[0054] s1. Add graphene oxide into deionized water to form a solution of 1 mg / ml. After ultrasonic oscillation and dispersion, perform magnetic stirring. During the stirring process, add thiourea and L-ascorbic acid to obtain a mixed solution, in which the mass of thiourea and graphene oxide The ratio is 8:1, the mass ratio of L-ascorbic acid to graphene oxide is 7:1, then drip ammonia water to adjust the pH of the mixed solution to pH=7.8, and continue to stir to obtain a uniform and stable suspension;

[0055] s2. Transfer the suspension to the reaction kettle, seal it and put it in a constant temperature drying oven, heat it at 170°C for 14 hours, take it out after natural cooling, vacuum filter the suspension in the reaction kettle, and then use ethanol and remove Washing with ionic water and freez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com