Water-based vinylidene chloride copolymer resin and preparation method thereof

A vinylidene chloride copolymer resin and vinylidene chloride technology, which is applied in the field of water-based vinylidene chloride copolymer resin and its preparation, can solve the problems of affecting the compactness of the coating, peeling off of the paint film, and poor compatibility, so as to improve the adhesion and The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of aqueous vinylidene chloride copolymer resin of the present invention, comprises the following steps:

[0024] (1) Add vinylidene chloride, acrylate, functional monomer, emulsifier, molecular weight modifier and water into the reactor, stir under ice bath for pre-emulsification, and obtain pre-emulsion, wherein the emulsifier is dodecyl Sodium sulfonate and alkyl glucoside, the consumption of emulsifier is 1%~3% of the total mass of vinylidene chloride, acrylate and functional monomer, wherein the mass percentage example of sodium dodecyl sulfonate and alkyl glycoside is ( 45~50)%: (50~55)%;

[0025] (2) Under the protection of an inert gas, the temperature of the reaction system was raised to 36°C, and the initiator sodium bisulfite and ammonium persulfate aqueous solutions were added respectively. The initiator was 0.1-0.5% of the total mass of vinylidene chloride, acrylate and functional monomers %, constant temperature reaction to pre...

Embodiment 1

[0042] Dissolve 1.00g sodium dodecylsulfonate and 1.15g alkyl glucoside in 110g deionized water, stir until the emulsifier is completely dissolved, add 20.00g butyl acrylate, 70.00g vinylidene chloride, 3.10g acrylic acid under ice bath conditions , 2.50g 2-hydroxyethyl methacrylate phosphate, 0.20g 2-mercaptobutyric acid, emulsified at high speed for 30 minutes to obtain a pre-emulsion.

[0043] Transfer the pre-emulsion to the reactor, vacuumize and fill with nitrogen three times, heat up to 36°C, add 0.18g ammonium persulfate dissolved in 1mL water and 0.12g sodium bisulfite dissolved in 1mL water, react at constant temperature for 4 hours, heat up To 45°C, continue to react for 2 hours, cool down, filter and discharge to obtain vinylidene chloride copolymer resin: solid content is 47%, viscosity at 25°C is 250mPa·s, pH is 1.8.

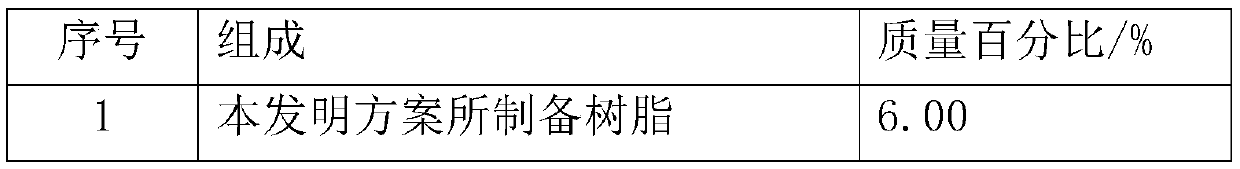

[0044] Use the vinylidene chloride copolymer resin in Example 1 to prepare water-based vinylidene chloride coating according to the formula in Tab...

Embodiment 2

[0049] Dissolve 1.15g sodium dodecylsulfonate and 1.25g alkyl glycoside in 95g deionized water, stir until the emulsifier is completely dissolved, add 7.00g butyl acrylate, 13g isooctyl acrylate, 70.00g partial Vinyl chloride, 3.10 g of acrylic acid, 2.80 g of 2-hydroxyethyl methacrylate phosphate, and 0.40 g of ethyl 3-mercaptobutyrate were emulsified with high-speed stirring for 30 minutes to obtain a pre-emulsion.

[0050] Transfer the pre-emulsion to the reactor, vacuumize and fill with nitrogen three times, heat up to 36°C, add 0.18g ammonium persulfate dissolved in 1mL water and 0.12g sodium bisulfite dissolved in 1mL water, react at constant temperature for 6 hours, and heat up To 45°C, continue to react for 2 hours, cool down, filter and discharge to obtain adhesion-enhancing resin: solid content is 51%, viscosity at 25°C is 320mPa·s, pH is 2.2.

[0051] With the vinylidene chloride copolymer resin in embodiment 2, according to embodiment 1 scheme system paint and coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com