Magnetic conductive PID-resistant adhesive film and solar cell module

A solar cell and magnetic technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of easy agglomeration of inorganic powders and poor anti-PID performance, and achieve strong adsorption, good conductivity, and high anti-PID performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Another aspect of the application also provides a preferred double-layer magnetic conductive anti-PID adhesive film preparation method, the preparation method comprising:

[0035] preparing raw materials for forming the first film layer according to a predetermined ratio;

[0036] preparing raw materials for forming the second transparent film layer according to a predetermined ratio;

[0037] The raw materials used to form the first film layer and the raw materials used to form the second transparent film layer are simultaneously melted and co-extruded, or calendered and extruded to obtain the required double-layer magnetic conductive anti-PID adhesive film.

[0038] Another aspect of the present application also provides a solar cell assembly, which includes the above-mentioned magnetic conductive anti-PID adhesive film.

[0039] Fe 3 o 4 With strong adsorption and good conductivity, it can absorb ions and transfer them to the frame of the module. By readjusting th...

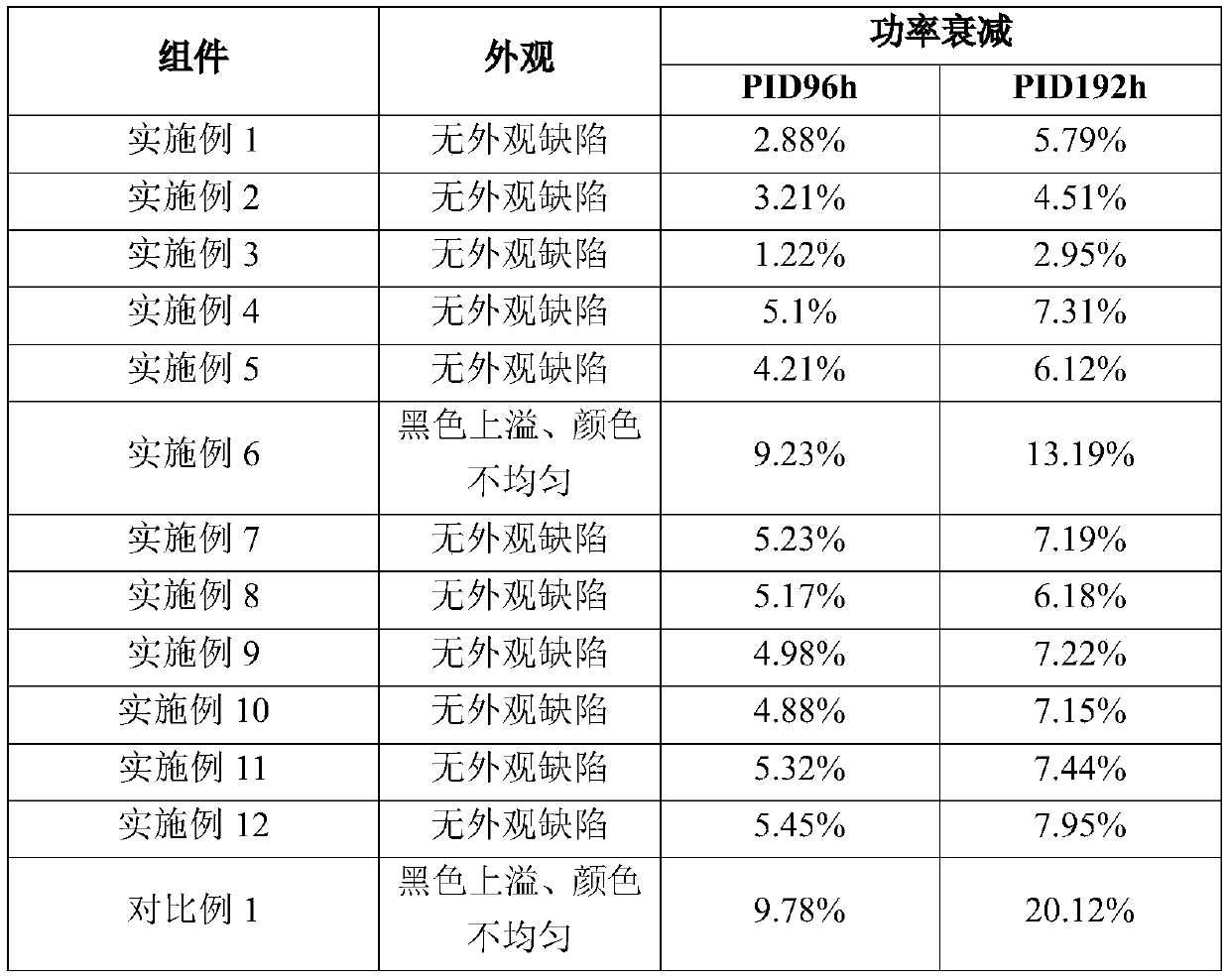

Embodiment 1

[0046] 1. Preparation of magnetic conductive black anti-PID double-layer adhesive film

[0047] (1) 100 parts of ethylene-vinyl acetate copolymer, 0.2 parts of modifying additive 3-(methacryloyl chloride) propyltrimethoxysilane, 0.1 part of crosslinking additive trimethylolpropane triacrylic acid Esters and 0.1 part of crosslinking aid trimethylolpropane trimethacrylate, 0.3 part of thermal oxygen aging agent 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-di Methylbenzyl)-1,3,5-triazine-2,4,6-(1H, 3H,5H)-trione was mixed evenly, poured into the silo of the first single-screw extruder, and waited use;

[0048] (2) 100 parts of ethylene-vinyl acetate copolymer, 50 parts of Fe with a particle size of 2 to 3 μm 3 o 4 Powder, 0.2 parts of modified auxiliary agent 3-(methacryloyl chloride) propyl trimethyloxysilane, 0.1 part of cross-linking auxiliary agent trimethylolpropane triacrylate and 0.1 part of cross-linking auxiliary agent trihydroxy Methyl propane trimethacrylate, 0.3 part ant...

Embodiment 2

[0060] 1. Preparation of magnetic conductive black anti-PID double-layer adhesive film

[0061] (1) 100 parts of ethylene-alpha-olefin copolymer resin, 0.2 part of modification aid vinyltrimethoxysilane, 0.1 part of crosslinking aid trimethylolpropane trimethacrylate and 0.1 part of crosslinking agent Auxiliary pentaerythritol triacrylate, 0.3 parts of anti-heat and oxygen aging agent 2,2'-methylene-bis-(4-ethyl-6-tert-butylphenol) mixed evenly, poured into the first single-screw extrusion In the machine silo, ready for use;

[0062] (2) 100 parts of ethylene-α-olefin copolymer resin, 70 parts of Fe with a particle size of 2 to 3 μm 3 o 4 Powder, 0.2 parts of modified auxiliary agent vinyltrimethoxysilane, 0.1 part of cross-linking auxiliary agent trimethylolpropane trimethacrylate and 0.1 part of cross-linking auxiliary agent pentaerythritol triacrylate, 0.3 part of anti-hot oxygen The aging agent 2,2'-methylene-bis-(4-ethyl-6-tert-butylphenol) is mixed evenly, poured into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com