Biological deodorization filler and trickling filter for removing odor of landfill leachate by using filler

A biological deodorization and trickling filter tower technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of poor biological trickling filter tower processing capacity, limited hydrophilic and moisturizing performance, intolerant of strong acid and corrosion resistance, etc. Achieve stable deodorization efficiency, good hydrophilic and moisturizing performance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

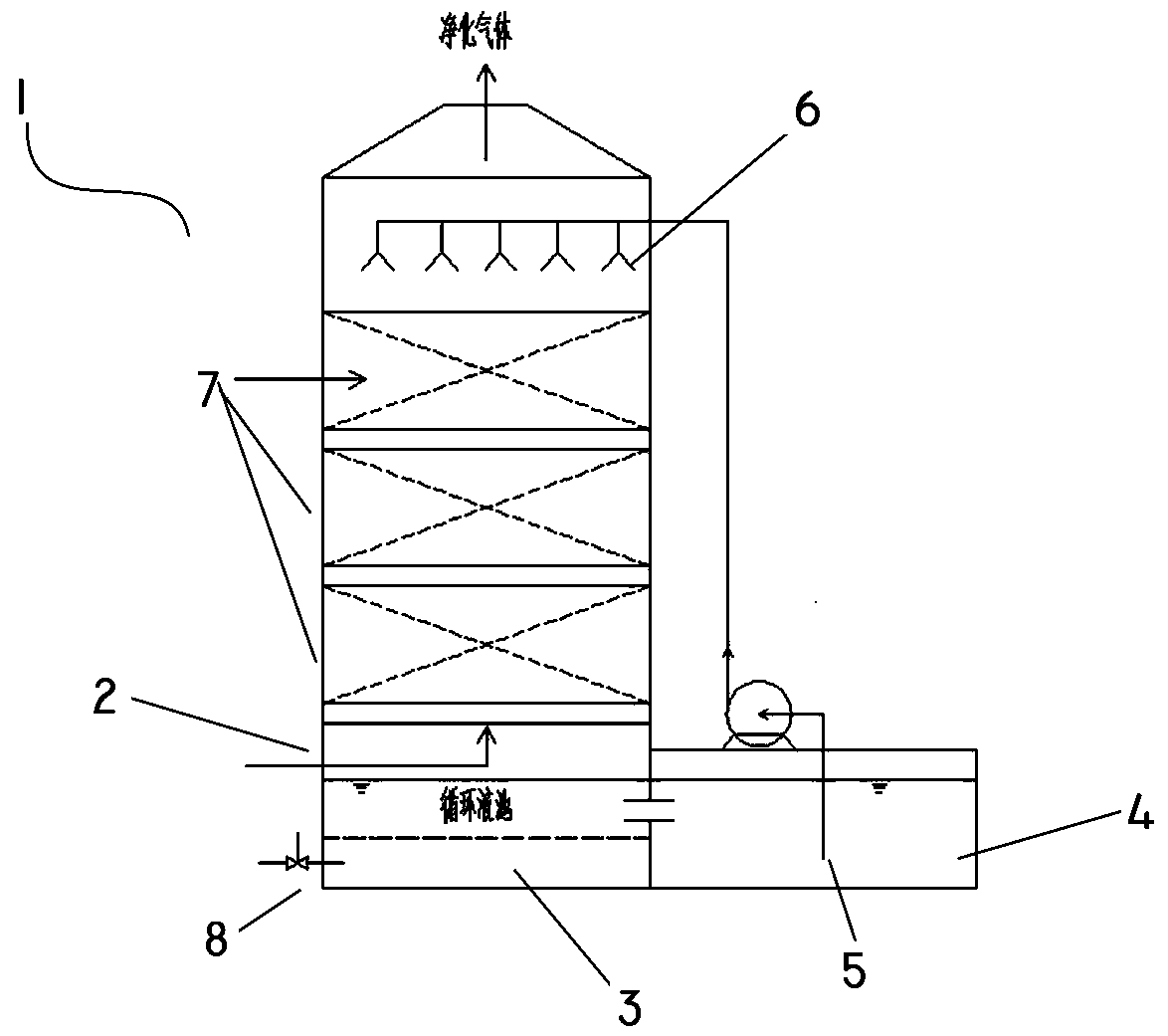

[0031] The invention provides a biological deodorization filler and a trickling tower using the filler to remove the stench of landfill leachate. Specifically, the biological deodorization filler includes activated carbon-loaded polyurethane and modified polypropylene; wherein, activated carbon-loaded polyurethane: modified polypropylene The mass ratio is 3:3.5. The particle size of the filler is 2-20mm; the specific surface area is 200-300m 2 / g.

[0032] Among them, the activated carbon-loaded polyurethane filler is prepared by adding polyisocyanate, MLZ polymer water-absorbing agent and activated carbon, and has a microporous and macroporous cross-linked network structure and strong surface water absorption, which is more conducive to the growth of microorganisms. hanging film.

[0033] Modified polypropylene biological filler is a modified filler made of magnetic powder, polyvinyl alcohol stearate, mixed with polypropylene particles wetted by dispersed lubricant, and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com