A kind of preparation method of polyvinylidene fluoride hollow fiber hollow fiber microporous membrane with large flux removal virus

A polyvinylidene fluoride, high-flux technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as reduced virus retention performance, low pure water flux, and impact on water safety. Expand the effective filtration area, improve the flux of pure water, and improve the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

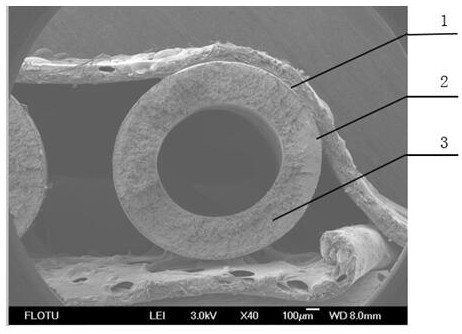

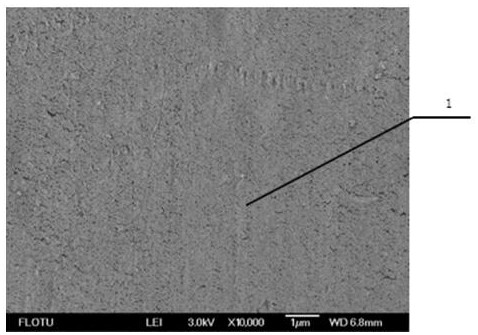

[0037] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 25wt%, and diethyl phthalate as diluent, the mass percentage concentration is 75wt%, and the temperature is raised to 220°C, stand still for degassing and mix uniformly to obtain a casting solution.

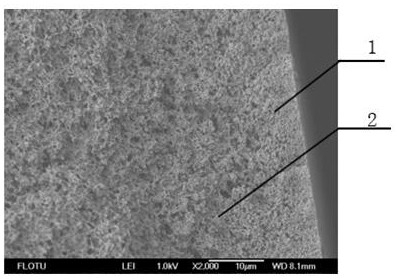

[0038] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 7°C. The core liquid is glycerol.

[0039] (3) Outer layer spray-solvent exchange ...

Embodiment 2

[0045] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 20wt%, diethyl phthalate as diluent, mass concentration is 80wt%, and the temperature is raised to At 220°C, let stand to defoam and mix evenly to obtain a casting solution.

[0046] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 10°C. The core fluid is 1,2-propanediol.

[0047] (3) Outer layer spray-solvent exchange film formation: th...

Embodiment 3

[0053] (1) Preparation of casting solution: diluent and polyvinylidene fluoride copolymer, wherein the mass concentration of polyvinylidene fluoride copolymer is 30wt%, diethyl phthalate as diluent, mass concentration is 70wt%, and the temperature is raised to 220°C, stand still for defoaming and mix evenly to obtain casting solution;

[0054] (2) Extrusion of hollow fiber membrane: The casting solution is further sheared and melted at high temperature through a twin-screw extruder, and finally merged with the inner core solution and the outer spray layer at the spinneret. One is extruded through the spinneret to form a hollow fiber-shaped homogeneous high-temperature casting film solution with a high-temperature core liquid in the inner cavity and a low-temperature spray layer around the outside. The outer spray consists of 20% ethanol and 80% water at a temperature of 5°C. The inner core fluid is composed of glycerol and 2,3-butanediol mixed in any proportion.

[0055] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com