Polyimide, preparation method of precursor solution of polyimide and double-sided flexible copper-clad plate

A polyimide and precursor solution technology, which is applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of low yield and production efficiency of double-sided flexible copper clad laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

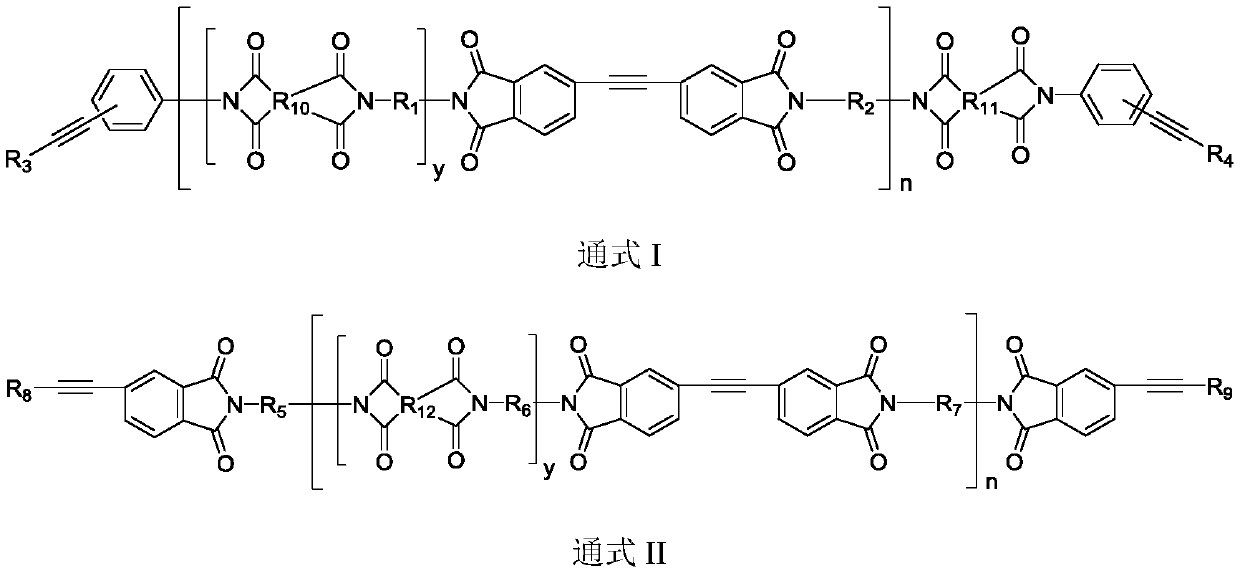

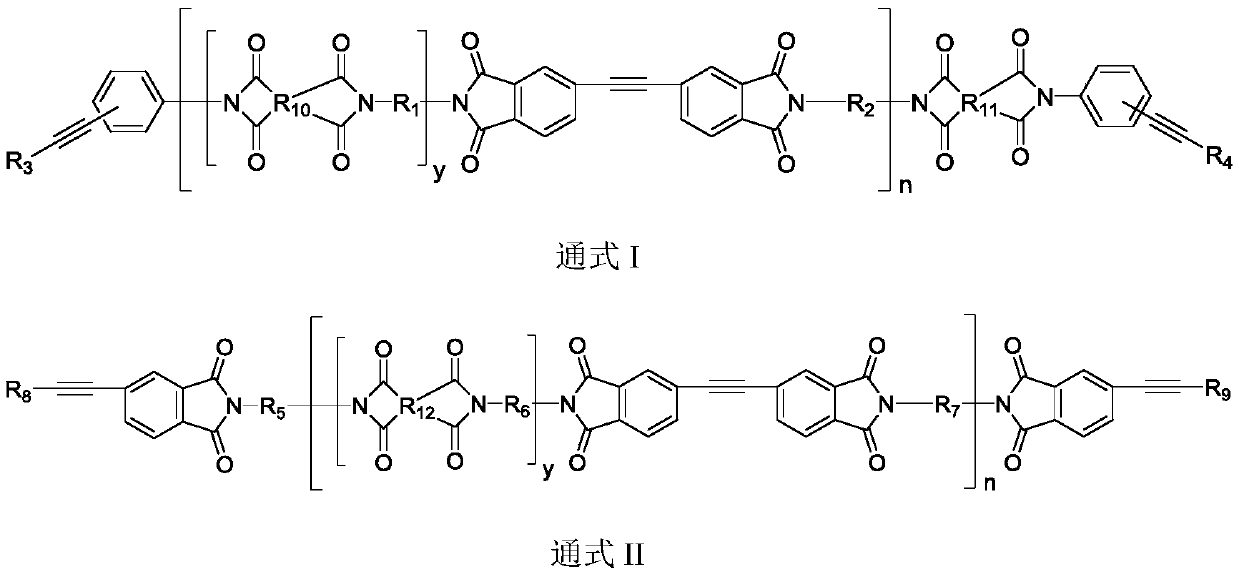

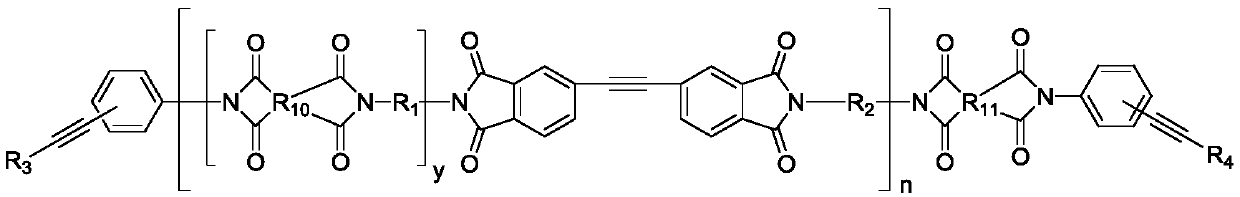

[0054] The preparation method of the above precursor solution comprises: mixing aniline compounds containing alkyne groups and aromatic diamine compounds with an organic solvent to obtain a mixed solution of organic amines, the mass concentration of the mixed solution of organic amines being 6-12%; Mix tetracarboxylic dianhydride compounds with 4,4'-(acetylene-1,2-diyl) diphthalic anhydride to obtain an acid anhydride mixture; under an inert atmosphere, divide the anhydride mixture three times according to the mass ratio of 6:3:1 react with an organic amine mixed solution, and the reaction temperature is 30-40°C to obtain a polyimide precursor solution with general formula I, or

[0055] Mix the aromatic diamine compound with an organic solvent to obtain an organic amine mixed solution, the mass concentration of the organic amine mixed solution is 6-12%; mix alkyne-containing phthalic anhydride compounds, aromatic tetracarboxylic dianhydride compounds and 4 , 4'-(acetylene-1,2...

preparation Embodiment 1~8

[0065] Prepared according to the amount of raw material input in Table 1 and the following experimental procedures: under a nitrogen atmosphere, in a 100mL three-necked flask, while stirring, the quantitative alkyne-containing aniline compounds and aromatic diamines shown in Table 1 The compounds were dissolved in 40g of strong polar solvent NMP, and then the aromatic tetracarboxylic dianhydride compounds and 4,4'-(acetylene-1, 2-diyl) diphthalic anhydride, and then, under a nitrogen atmosphere, the solution was stirred at room temperature for about 24 hours to obtain a corresponding thermosetting / thermoplastic polyimide precursor solution. Measure the glass transition temperature of the polyimide resin corresponding to each polyimide precursor solution by the DMA test method, and use A, C, E, G as the thermosetting polyimide precursor solution according to the glass transition temperature , B, D, F, H as thermoplastic polyimide precursor solutions.

[0066] Table 1

[0067]...

preparation Embodiment 9~16

[0071] Prepared according to the amount of raw material input in Table 2 and the following experimental procedures: under a nitrogen atmosphere, in a 100mL three-necked flask, dissolve the quantitative aromatic diamine compounds shown in Table 2 in 40g of highly polar In the solvent NMP, add the alkyne-containing phthalic anhydride compounds, aromatic tetracarboxylic dianhydride compounds and 4,4'-(acetylene-1, 2-diyl) diphthalic anhydride. Then, under a nitrogen atmosphere, the solution was continuously stirred at room temperature for about 24 hours to prepare a corresponding thermosetting / thermoplastic polyimide precursor solution. Through the DMA test method, the glass transition temperature of the polyimide resin corresponding to each thermosetting / thermoplastic polyimide precursor solution is measured, and I, K, M, O are used as thermosetting polyimides according to the glass transition temperature Precursor solution, J, L, N, P as thermoplastic polyimide precursor solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com