SNCR denitration system and method for removing escaping ammonia in SNCR denitration process

A ammonia escape and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of small processing capacity, removal of trace ammonia with difficult ppm content, no ammonia escape removal, etc., achieving low cost, Effects with obvious effects and important application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

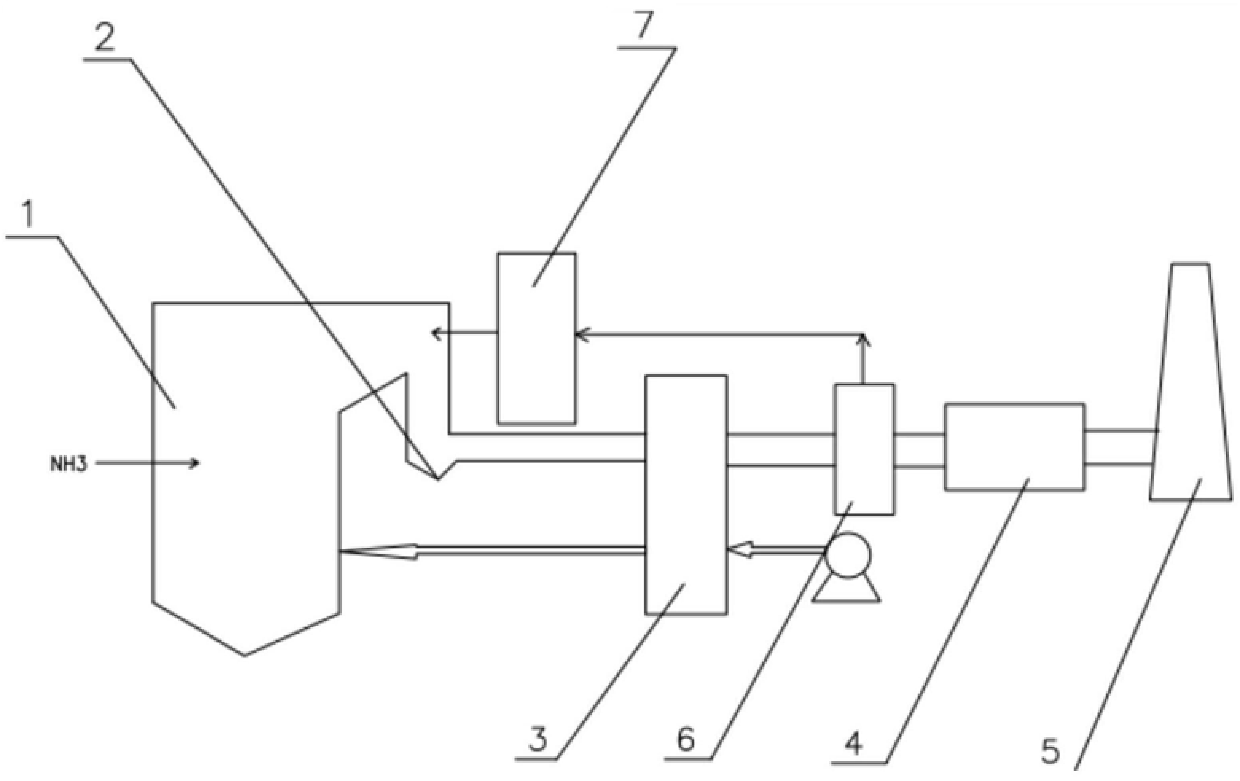

[0035] A SNCR denitrification system, such as figure 1 As shown, it includes denitration reaction zone 1, economizer 2, air preheater 3, dust collector 6, desulfurization tower 4 and chimney 5, denitration reactor, economizer 2, air preheater 3, dust collector 6, The connection mode between the desulfurization tower 4 and the chimney 5 is well known to those skilled in the art, and will not be repeated here.

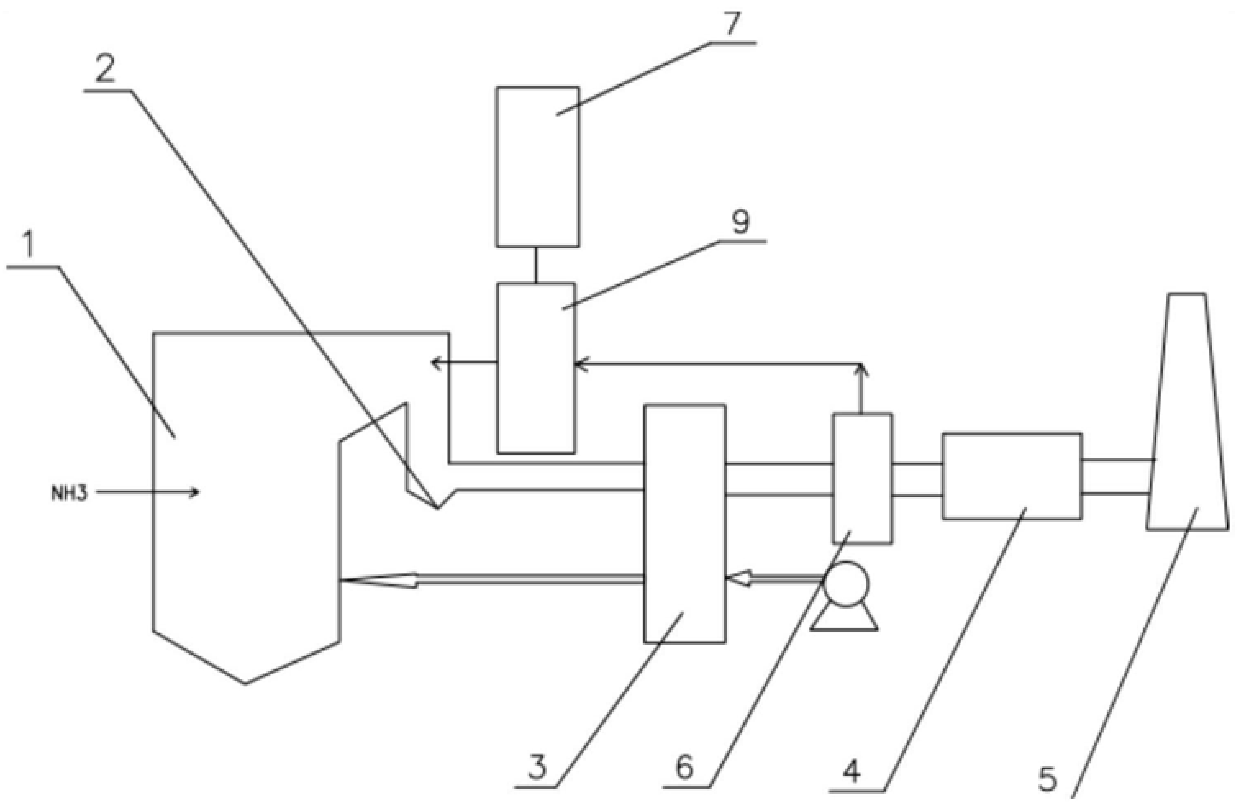

[0036] The SNCR denitrification system also includes a pneumatic conveying device 9 and an ammonia conversion catalyst supply device 7 .

[0037] The ammonia conversion catalyst supply device 7 is connected to the gas outlet flue of the denitration reactor through a pneumatic conveying device 9, and the pneumatic conveying device 9 is arranged between the economizer 2 and the denitration reactor.

[0038] The dust outlet of the dust remover 6 is connected with the feed inlet of the ammonia conversion catalyst supply device 7 .

[0039] The pneumatic conveying device 9 in...

Embodiment 2

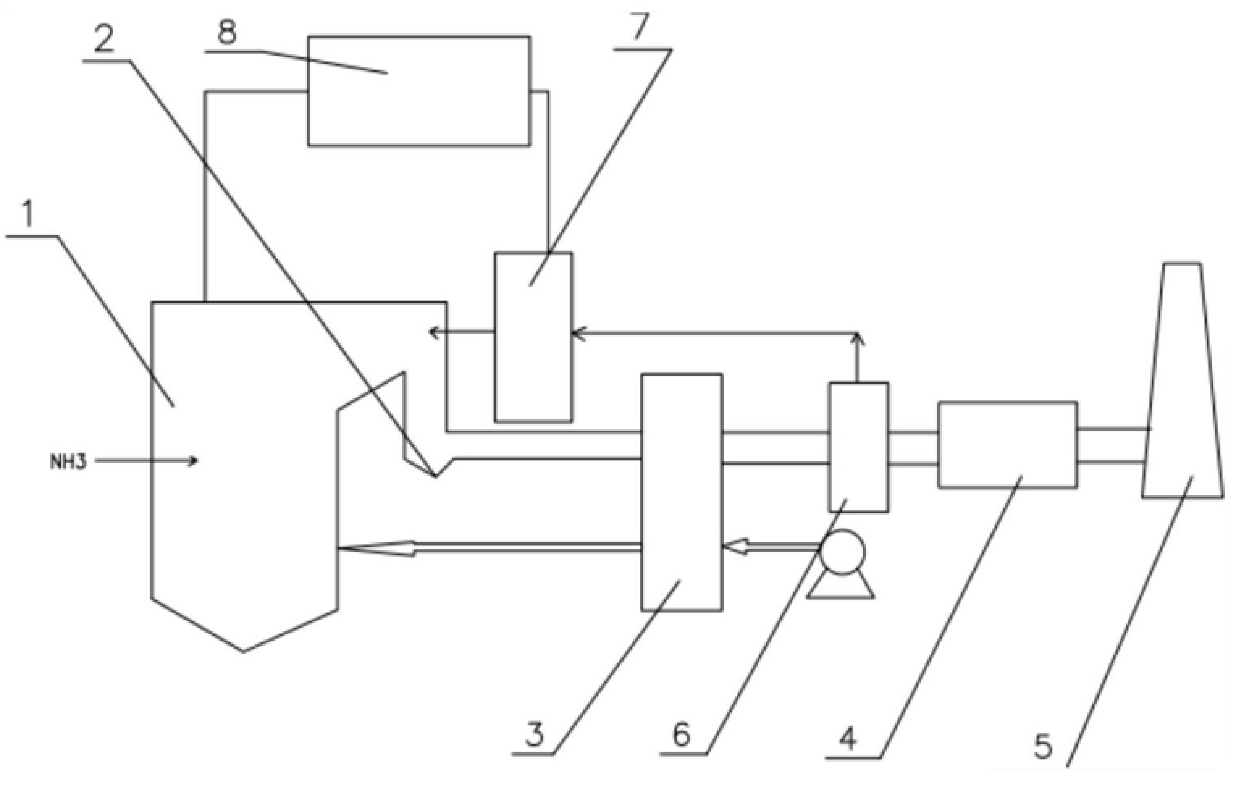

[0042] An SNCR denitrification system, comprising a denitrification reaction zone 1, an economizer 2, an air preheater 3, a dust collector 6, a desulfurization tower 4 and a chimney 5, a denitrification reactor, an economizer 2, an air preheater 3, and a dust collector The connection mode between device 6, desulfurization tower 4 and chimney 5 is known to those skilled in the art, and will not be repeated here;

[0043] The SNCR denitrification system also includes a pneumatic mixing device 8 and an ammonia conversion catalyst supply device 7;

[0044] The pneumatic mixing device 8 is connected to the ammonia conversion catalyst supply device 7 and the gas outlet flue of the denitration reactor respectively, and the pneumatic mixing device 8 is arranged between the denitration reactor and the economizer 2;

[0045] The air inlet of the dust remover 6 is connected with the air outlet of the pneumatic mixing device 8, and the dust outlet of the dust remover 6 is connected with t...

Embodiment 3

[0049] The flue gas treated by the SNCR denitrification system described in Example 1 is the flue gas of a certain waste incineration power generation, with a flue gas volume of 50,000 Nm³ / h. The powder is entrained into the flue and mixed with the flue gas. The amount of new catalyst added is 0.1kg / Nm³ (5kg / h), the circulating catalyst is 100kg / h, and the NOx concentration in the flue gas is reduced from 100mg / Nm³ to 60mg / Nm³; the outlet ammonia concentration Reduced from 50mg / Nm³ to 5mg / Nm³, the amount of ammonia escape is less than 3ppm, and the emission of flue gas meets the latest European standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com