Method for improving oil absorption performance of polypropylene fibers by utilizing super-hydrophobic modification

A polypropylene fiber, super-hydrophobic modification technology, applied in the direction of separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve the difficult control of the grafting reaction process, complex modification process, High preparation cost and other problems, to achieve the effect of high reusability, simple modification process and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh a certain amount of copper oxide particles with a particle size of 50nm and dissolve them in acetone, and obtain a copper chloride solution with a concentration of 0.5g / L after ultrasonication for 1h, immerse the clean polypropylene fiber in the above copper oxide solution, and continue After ultrasonication for 1 hour, the polypropylene fiber was taken out from the copper chloride solution, cleaned thoroughly and placed in an oven. After heating at 60°C, 70°C and 80°C for 1h, 2h, and 3h respectively, rough nanofibers were obtained. Polypropylene fiber surface. Prepare a concentration of 0.1 with ethanol as solvent

[0019] mol / L palmitic acid solution, immerse the polypropylene fiber obtained above into the palmitic acid solution for curing reaction, and then fully wash the modified polypropylene fiber with ethanol after 0.5h, then put it in an oven at 60°C The superhydrophobic modified polypropylene fibers were obtained after 6 hours of heating.

Embodiment 2

[0021] Weigh a certain amount of copper oxide particles with a particle size of 25nm and dissolve them in ethanol, and obtain a copper chloride solution with a concentration of 0.8g / L after ultrasonication for 0.5h, immerse the clean polypropylene fiber in the above copper oxide solution, After continuing to sonicate for 1 hour, the polypropylene fiber was taken out from the cupric chloride solution, thoroughly washed and placed in an oven, and heated at 60°C, 70°C and 80°C for 0.5h, 1h, and 2h respectively, and obtained Polypropylene fibers with rough nanosurfaces. Use diethyl ether as a solvent to prepare a palmitic acid solution with a concentration of 0.3mol / L, immerse the polypropylene fiber obtained above to carry out a curing reaction, and then use methanol to fully wash the modified polypropylene fiber after 1 hour, and then After being put into an oven and heated at 60° C. for 8 hours, superhydrophobic modified polypropylene fibers were obtained.

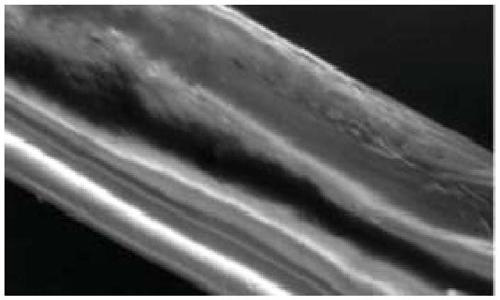

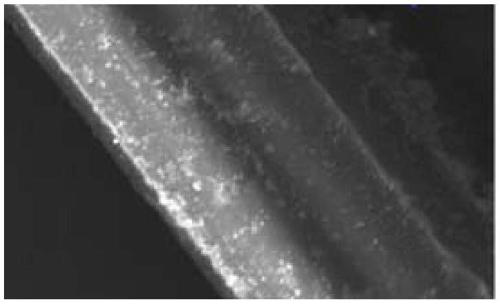

[0022] figure 1 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com