Method for performing biogas desulfurization and decarburization by combining solid waste and waste alkali liquor

A solid waste and biogas desulfurization technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of natural gas purification reaching the pipeline transmission standard, adding traditional treatment technology, and poor stability of membrane performance, etc., achieving good application prospects, The effect of increasing the reaction rate and increasing the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) make a suspension slurry of 200g (fly ash) / L (waste lye) according to the solid-to-liquid ratio of 30g / L waste lye with a dry fly ash and sodium hydroxide concentration;

[0030] 2) Experiments were carried out using simulated biogas containing 40% of the volume fraction of carbon dioxide and 3% of the volume fraction of hydrogen sulfide, and the rest being methane;

[0031] 3) Pass the suspension slurry in step 1) and the simulated biogas in step 2) to the spray tower at 80°C, with a liquid-to-gas ratio of 15L / m 3 Desulfurization and decarburization reaction under the condition;

[0032] 4) The suspension after the desulfurization and decarbonization reaction is separated from solid and liquid by sedimentation and filtration, and the solid waste is collected for the production of building materials and other products, and the waste lye is discharged from the system;

[0033] 5) Use a flue gas analyzer to analyze the concentration of carbon dioxide and hydrogen sulf...

Embodiment 2

[0038] Adopting sodium hydroxide is the spent lye of main component, adopts a kind of in fly ash, steel slag, tailings slag as solid raw material, other conditions and parameters are with embodiment 1, by table 2 experimental result it can be seen that adopting fly ash effect is the best Well, this is due to the high content of basic oxides in fly ash, which is conducive to the desulfurization and decarburization reactions.

[0039] Table 2 The removal rate of desulfurization and decarbonization reaction of different solid waste raw materials

[0040] Solid Waste Raw Materials fly ash Carbide slag steel slag Tailings Carbon dioxide removal rate (%) 88 86 82 84 Hydrogen sulfide removal rate (%) 89 82 87 90

Embodiment 3

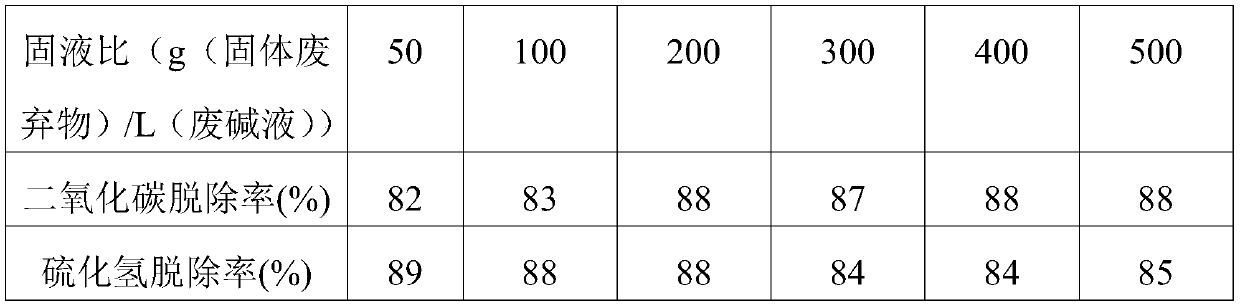

[0042] Using sodium hydroxide as the main component of waste lye and fly ash as raw materials, the solid-liquid ratio is 50g (solid waste) / L (waste lye), 100g (solid waste) / L (waste lye), 200g (solid waste) / L (waste lye), 300g / L (waste lye), 400g (solid waste) / L (waste lye), 500g (solid waste) / L (waste lye) , other conditions and parameters are with embodiment 1, and as known from table 3, solid-to-liquid ratio is 200g (solid waste) / L (waste lye) reaction effect is the best. In this system, the solid waste mainly plays the role of removing carbon dioxide, and the lye mainly plays the role of removing hydrogen sulfide. Under the relatively moderate solid-liquid ratio conditions, the desulfurization and decarbonization reactions can achieve high efficiency.

[0043] Table 3 The removal rate of desulfurization and decarburization reaction with different solid-liquid ratios

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com