Phenanthroline polymer, and preparation method and application thereof

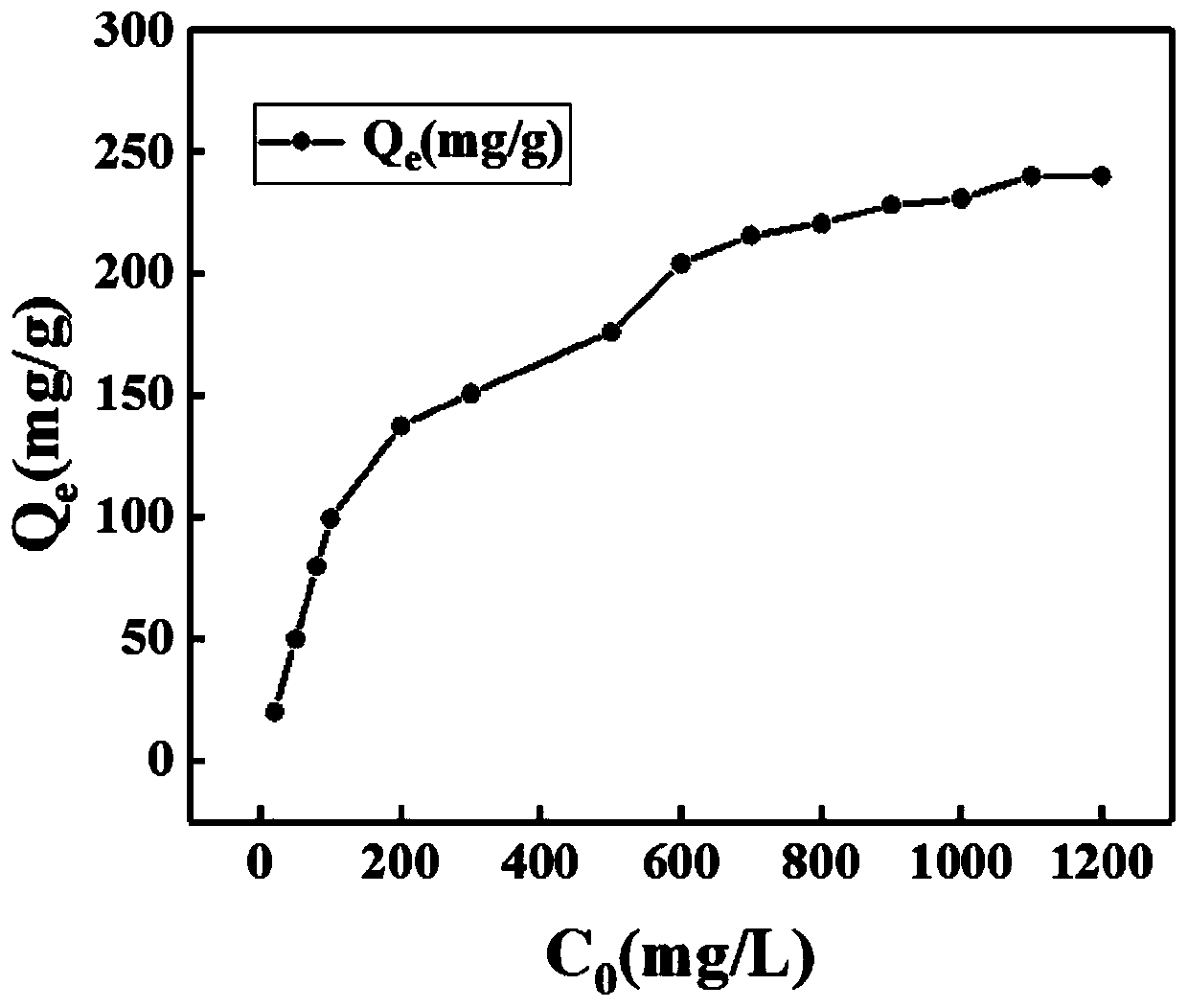

A technology of o-phenanthroline and polymers, applied in the field of o-phenanthroline polymers and its preparation, can solve the problems of few polymer exposure sites, low heavy metal ion adsorption capacity, complex synthesis steps, etc., and achieve easy operation , High adsorption capacity, large adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of o-phenanthroline polymer, comprises the following steps:

[0022] The acetonitrile solution of 1,10-phenanthroline is mixed with an oxidizing agent to carry out oxidative polymerization to obtain o-phenanthroline polymer.

[0023] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

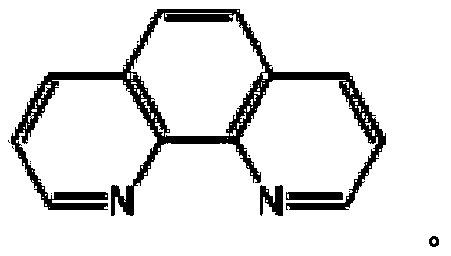

[0024] The invention mixes the acetonitrile solution of 1,10-phenanthroline and the oxidizing agent. In the present invention, the 1,10-phenanthroline is used as a monomer for preparing the o-phenanthroline polymer, and the structural formula of the 1,10-phenanthroline is:

[0025]

[0026] In the present invention, in the acetonitrile solution of 1,10-phenanthroline, the concentration of 1,10-phenanthroline is 0.15-0.30 mol / L, more preferably 0.25 mol / L. In the present invention, the preparation process of the acetonitr...

Embodiment 1

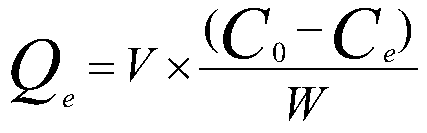

[0046] Take 1mol 1,10-phenanthroline monomer and place it in a round-bottomed flask, add 160mL acetonitrile and sonicate until it is completely dissolved, and obtain a solution with a concentration of 0.25mol / L; prepare a 0.25mol / L ammonium persulfate (APS) aqueous solution; Slowly add 40mL APS aqueous solution into the flask, vacuumize and ventilate nitrogen protection, turn on the stirring switch, set the stirring speed to 550r / min, turn on the heating switch, set the oil bath temperature to 70°C, carry out the oxidative polymerization reaction for 15 hours, and keep the device sealed; after the reaction , the resulting reaction system was cooled to room temperature, left to stand for 2h, and the supernatant was separated; the lower layer was added to deionized water (the volume ratio of the lower layer to deionized water was 1:10), and filtered after standing for 6h; Put the product into acetonitrile, repeat ultrasonic ultrafiltration 5 times; put the obtained filtrate into ...

Embodiment 2

[0050] Take 1mol 1,10-phenanthroline monomer and place it in a round-bottomed flask, add 160mL acetonitrile and sonicate until it is completely dissolved, and obtain a solution with a concentration of 0.25mol / L; prepare a 0.25mol / L ammonium persulfate (APS) aqueous solution; Slowly add 40mL APS aqueous solution into the flask, vacuumize and ventilate nitrogen protection, turn on the stirring switch, set the stirring speed to 550r / min, turn on the heating switch, set the oil bath temperature to 70°C, carry out the oxidative polymerization reaction for 15 hours, and keep the device sealed; after the reaction , the resulting reaction system was cooled to room temperature, filtered after standing for 2 hours, the resulting filtrate was placed in acetonitrile, and ultrasonic ultrafiltration was repeated 5 times; the resulting filtrate was eluted in ultrapure water, ultrasonic 3min, pumped Filter, repeat ultrapure water elution-ultrasound-suction filtration 5 times; put the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com