Preparation method of caramel color by ammonium sulfite method

A technology of ammonium sulfite method and caramel color, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as dyspnea, prone to allergic reactions, tissue damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

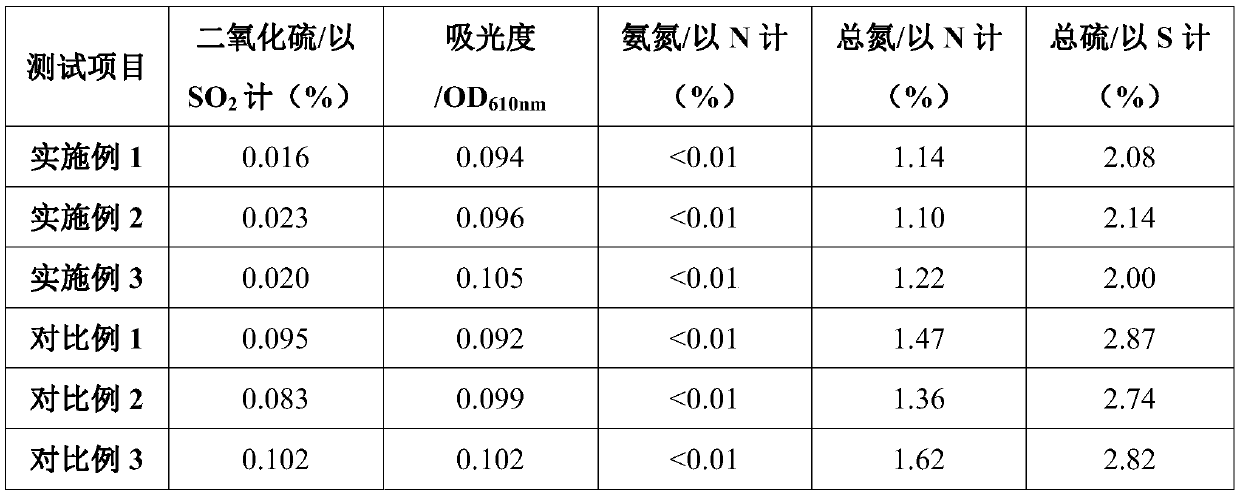

Examples

Embodiment 1

[0023] A kind of preparation method of ammonium sulfite method caramel color, comprises the following steps:

[0024] 1) Add glucose syrup with a solid content of 60% to the reactor, heat up to 80°C, then add 5% sodium sulfite on a dry basis of the glucose syrup and ammonium sulfate with 4% on a dry basis of the glucose syrup, and adjust the temperature in the reactor to 130 ℃, pressure to 0.10MPa, react for 30min;

[0025] 2) Adjust the temperature in the reactor to 120°C, the pressure to 0.05MPa, and react for 120min;

[0026] 3) Adjust the temperature in the reactor to 115°C, the pressure to 0.01MPa, and react for 180min;

[0027] 4) Rapidly adjust the temperature in the reactor to 50° C., the pressure to normal pressure, and filter to obtain caramel color.

Embodiment 2

[0029] A kind of preparation method of ammonium sulfite method caramel color, comprises the following steps:

[0030] 1) Add fructose syrup with a solid content of 75% to the reactor, heat up to 85°C, then add potassium sulfite with 15% dry basis of fructose syrup and ammonium phosphate with 5% dry basis of fructose syrup to adjust the reaction The temperature in the kettle is 132°C, the pressure is 0.12MPa, and the reaction is 45min;

[0031] 2) Adjust the temperature in the reactor to 123°C, the pressure to 0.08MPa, and react for 150min;

[0032] 3) Adjust the temperature in the reactor to 118°C, the pressure to 0.03MPa, and react for 150min;

[0033] 4) Quickly adjust the temperature in the reaction kettle to 55° C., the pressure to normal pressure, and filter to obtain caramel color.

Embodiment 3

[0035] A kind of preparation method of ammonium sulfite method caramel color, comprises the following steps:

[0036] 1) Glucose syrup with a solids content of 85% is added to the reactor, the temperature is raised to 90° C., and then sodium bisulfite and 1% ammonia on a dry basis of the glucose syrup and 1% of the dry basis of the glucose syrup are added (actually added is the mass Fraction of 26% ammonia water, and then converted to calculate the amount of ammonia), adjust the temperature in the reactor to 135 ° C, the pressure to 0.15 MPa, and react for 60 minutes;

[0037] 2) Adjust the temperature in the reactor to 125°C, the pressure to 0.10MPa, and react for 180min;

[0038] 3) Adjust the temperature in the reactor to 120°C, the pressure to 0.05MPa, and react for 120min;

[0039] 4) Rapidly adjust the temperature in the reactor to 60° C., the pressure to normal pressure, and filter to obtain caramel color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com