Wear-resistant anti-corrosion coating for underwater robot track protection and preparation method of wear-resistant anti-corrosion coating

An underwater robot and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of high cost of fluorine-containing substances, poor hydrophobicity, and bad influence on the environment, and achieve the goal of coating The layer has good hydrophobic performance, saves maintenance and replacement costs, and has a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

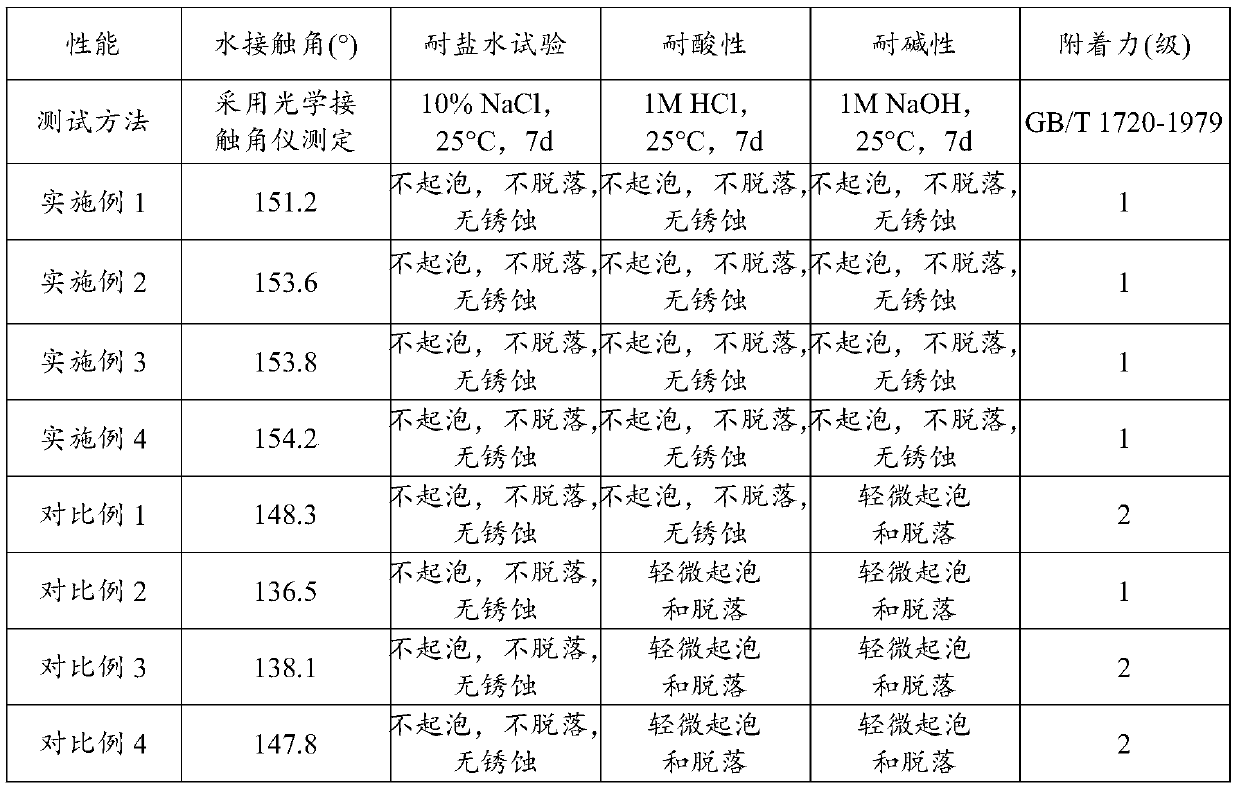

Examples

Embodiment 1

[0020] The preparation step of superhydrophobic coating material comprises the following:

[0021] 80 parts of polyurethane and 8 parts of dopamine were added to 80 parts of ethanol and placed in a high-energy ball mill for 4 hours to obtain ultrafine suspension A.

[0022] Add 10 parts of zinc oxide, 6 parts of silicon dioxide and 0.5 parts of polyvinylpyrrolidone into 20 parts of ethanol and 20 parts of water, heat to 40 ° C, ultrasonically disperse and stir vigorously for 30 minutes to make the mixture uniform, and obtain ZnO / SiO 2 Composite particle solution; add another 1.5 parts of stearic acid to the remaining 20 parts of ethanol and ultrasonically dissolve it for 10 minutes, then add the dissolved stearic acid solution to the ZnO / SiO 2 In the composite particle solution, heat and keep the temperature at 40°C, stir for 2 hours to make the reaction evenly mixed; finally add 1 part of γ-aminopropyltriethoxysilane, 1 part of zinc stearate, 0.3 part of antioxidant and 0.3 p...

Embodiment 2

[0026] The preparation step of superhydrophobic coating material comprises the following:

[0027] 90 parts of polyurethane and 9 parts of dopamine were added to 80 parts of ethanol and placed in a high-energy ball mill for 5 hours to obtain ultrafine suspension A.

[0028] Add 13 parts of zinc oxide, 7 parts of silicon dioxide and 1.0 part of polyvinylpyrrolidone to 20 parts of ethanol and 20 parts of water, heat to 40 ° C, ultrasonically disperse and stir vigorously for 30 minutes to make the mixture uniform, and obtain ZnO / SiO 2 Composite particle solution; add another 1.8 parts of stearic acid to the remaining 20 parts of ethanol and ultrasonically dissolve it for 10 minutes, then add the dissolved stearic acid solution to the ZnO / SiO 2 In the composite particle solution, heat and keep the temperature at 50°C, stir for 2.5 hours to make the reaction evenly mixed; finally add 2.0 parts of γ-aminopropyltriethoxysilane, 1.5 parts of zinc stearate, 0.6 parts of antioxidant and...

Embodiment 3

[0031] The preparation step of superhydrophobic coating material comprises the following:

[0032] 100 parts of polyurethane and 10 parts of dopamine were added to 80 parts of ethanol and placed in a high-energy ball mill for 6 hours to obtain ultrafine suspension A.

[0033] Add 16 parts of zinc oxide, 9 parts of silicon dioxide and 1.2 parts of polyvinylpyrrolidone to 20 parts of ethanol and 20 parts of water, heat to 40 ° C, ultrasonically disperse and stir vigorously for 30 minutes to make the mixture uniform, and obtain ZnO / SiO 2 Composite particle solution; add another 2.4 parts of stearic acid to the remaining 20 parts of ethanol and ultrasonically dissolve it for 10 minutes, then add the dissolved stearic acid solution to the ZnO / SiO 2 In the composite particle solution, heat and keep the temperature at 50°C, stir for 3 hours to make the reaction evenly mixed; finally add 2.5 parts of γ-aminopropyltriethoxysilane, 1.8 parts of zinc stearate, 0.6 parts of antioxidant an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com