Nitrogen-doped micro-mesoporous carbon/transition metal oxide composite material and preparation method thereof

A technology of transition metals and composite materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as uneven distribution of metal compound nanoparticles, unfavorable metal compound precursor solution infiltration, composite electrode material structure blockage, etc. , to achieve the effect of low cost, excellent performance and improved adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

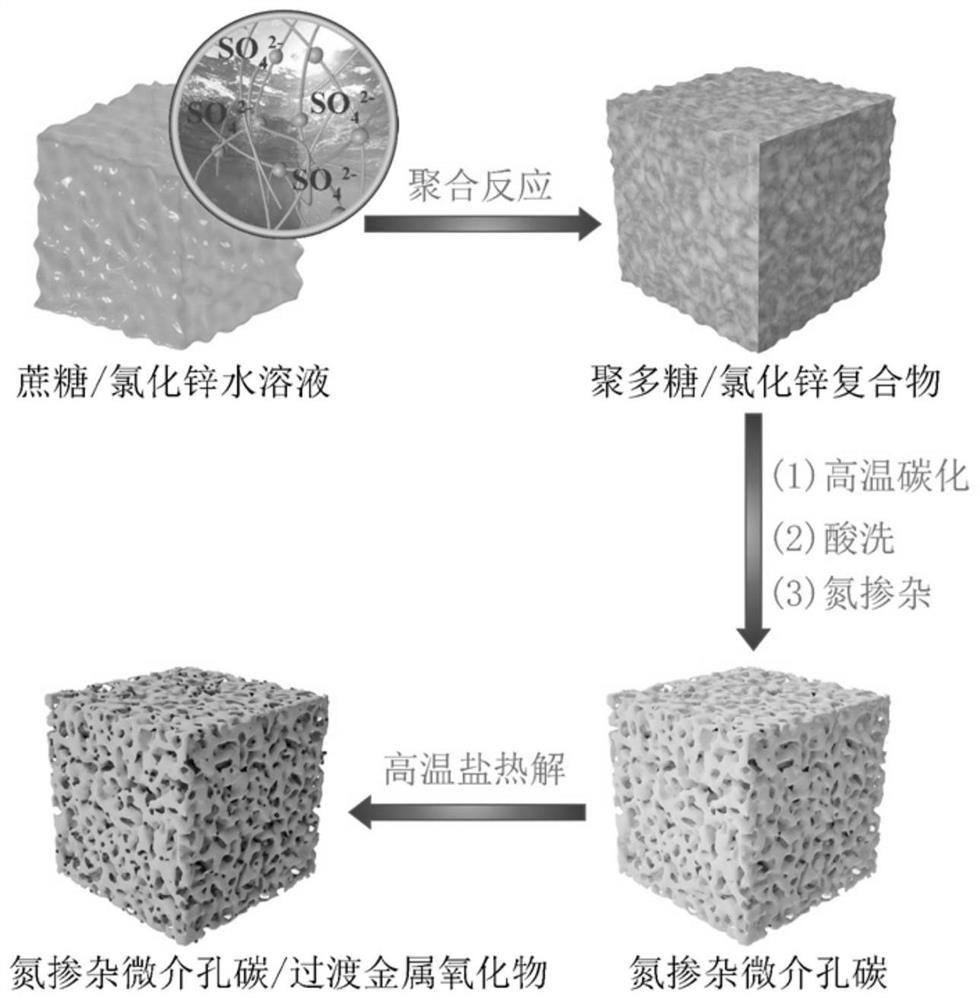

[0045] (1) Dissolve 5g of sucrose, 40g of zinc chloride and 0.55g of concentrated sulfuric acid in 30mL of deionized water under stirring, first react the mixed solution at 100°C for 6h, after the reaction is over, continue to react at 160°C for 6h, Prepare polysaccharide / zinc chloride complex;

[0046] (2) Take the polysaccharide / zinc chloride complex in step (1) and carry out high-temperature carbonization under an argon atmosphere, at 1°C min -1 The heating rate is raised to 900°C and kept for 2 hours, zinc chloride is sublimated at high temperature, and micro-mesoporous carbon containing a small amount of zinc-based compounds is obtained;

[0047] (3) Utilize the hydrochloric acid solution that concentration is 1mol / L to carry out pickling to the micro-mesoporous carbon containing a small amount of zinc-based compound in step (2), after removing wherein remaining zinc salt, obtain micro-mesoporous carbon;

[0048] (4) Mix 200 mg of the micro-mesoporous carbon prepared in ...

Embodiment 2

[0053] Steps (1)~(4) are identical with (1)~(4) in embodiment 1;

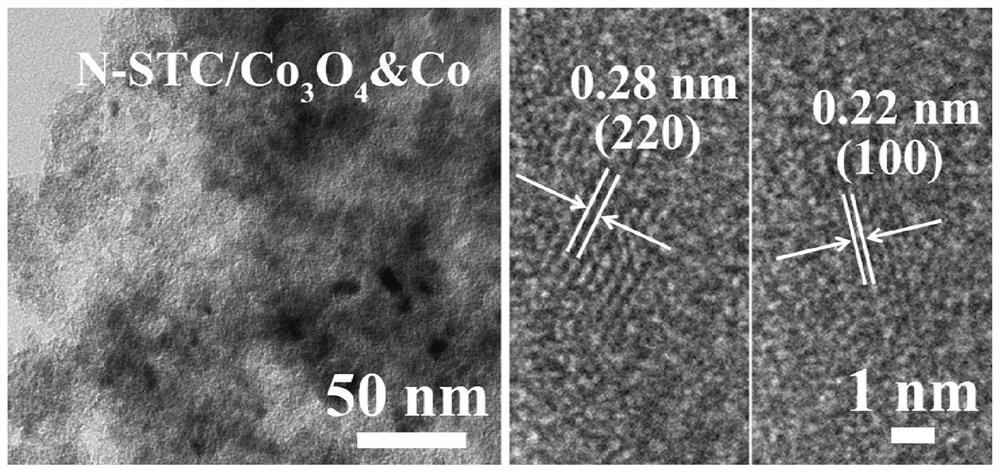

[0054] (5) Dissolve 40.2 mg of cobalt nitrate hexahydrate in 20 mL of ethanol;

[0055] (6) Slowly add the cobalt nitrate / ethanol solution in step (5) dropwise to 100 mg of N-STC, then dry at 60°C, and finally, pyrolyze the dried powder for 3 hours under an argon atmosphere , where the pyrolysis temperature is 500°C and the heating rate is 1°C min -1 , get N-STC / Co 3 o 4 &Co.

Embodiment 3

[0057] Steps (1)~(4) are identical with (1)~(4) in embodiment 1;

[0058] (5) Dissolve 43.1mg of nickel nitrate hexahydrate in 20mL of ethanol;

[0059] (6) Slowly add the nickel nitrate / ethanol solution in step (5) dropwise to 100mg of N-STC, then dry at 60°C, and finally, pyrolyze the dried powder for 3h under an argon atmosphere , where the pyrolysis temperature is 500°C and the heating rate is 1°C min -1 , to get N-STC / Ni 2 o 3 &NiO.

PUM

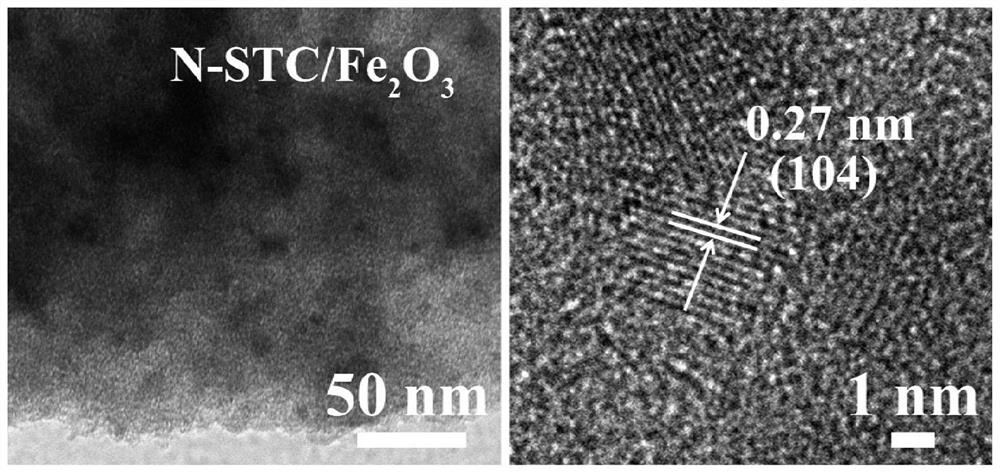

| Property | Measurement | Unit |

|---|---|---|

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com