Adsorption materials and methods for treating contaminants

A technology for adsorbing materials and pollutants, applied in the field of adsorbent materials for treating pollutants, can solve the problem of high implementation cost, and achieve the effects of reducing environmental damage, improving cell biological stability, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

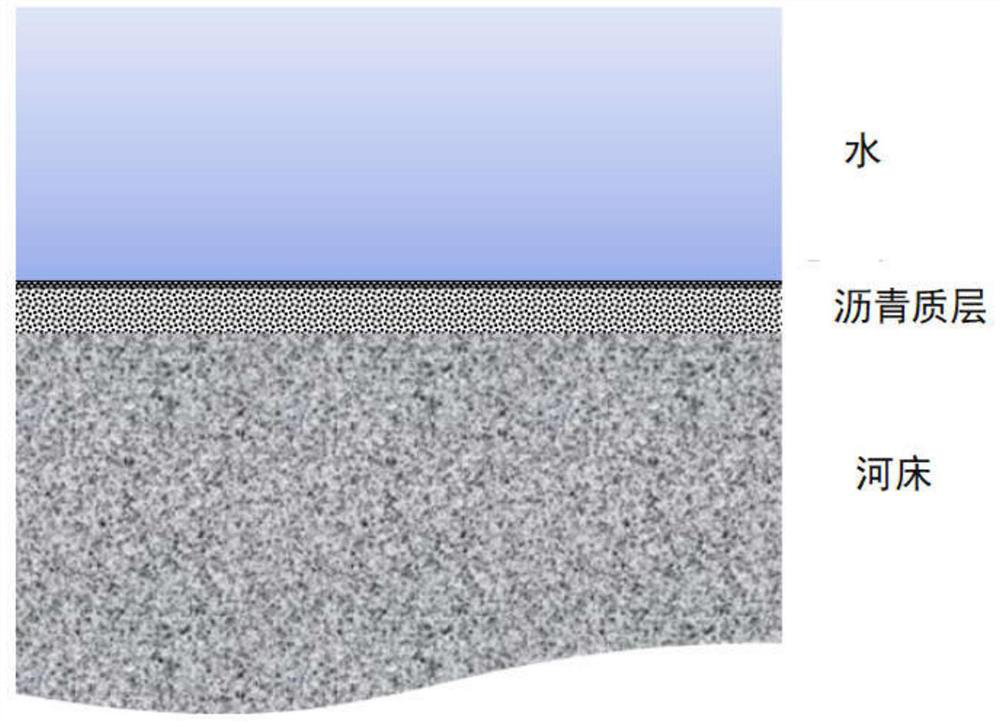

[0051] Example 1: Generation of Asphaltenes

[0052] The present invention is based on the results of a series of experimental studies aimed at determining the chemistry and reactivity of asphaltenes in the form of solid particles from "Deep step separation of heavy oils by coupled raffinate granulation" Method and Treatment System" (US Pat. No. 7,597,794) using feedstocks of mined Canadian athabasca oil and bitumen-derived vacuum residue (VR). Solid asphaltene was extracted from VR by a low-complexity and low-energy-intensity solvent-based separation method as documented (see Tables 1 and 2).

[0053] Tables 1 and 2 show the approximate and elemental analysis of the asphaltenes. The data show that asphaltenes from mineral oils and bitumen VR contain high contents of ash, sulfur and metals and were selected as representative samples to illustrate the extremes of petroleum asphaltenes utilization. Zhao et al. reported a comparison of the properties of various petroleum-derive...

Embodiment 2

[0059] Example 2: Evaluation of Asphaltene Leachability

[0060] A modified leachability test was performed on the asphaltenes described in Example 1.

[0061] The asphaltenes obtained in the above examples were sieved with a 150-mesh biological cell filter, and the asphaltene particles with particles larger than 100 microns were collected for the leachability test. Fill a 5 mL glass burette with 100 μl of glass beads until 2 mL is gradually level, then fill with 0.25 g of the above sieved 100 μm asphaltene particles. The first test was performed with deionized water.

[0062] Inject 5 mL of deionized water into the above-mentioned buret containing glass beads and asphaltene particles, and soak for 24 hours. After that, the leachate in the burette was drained drop by drop and collected. Add another 5 mL of fresh deionized water to the buret again. Similar soaking / leaching procedures were repeated three times to obtain a total of at least 10 mL of leachate; meanwhile, no as...

Embodiment 3

[0072] Example 3: Use of Asphaltenes for Water Treatment

[0073] The asphaltenes described in Example 1 were used as adsorbents for water treatment.

[0074] The asphaltenes obtained in the above examples were sieved with a 150-mesh biological cell filter, and the asphaltene particles with particles larger than 100 microns were collected for filtration test.

[0075] Fill a 5 mL glass burette with 100 μl of glass beads until the 2 mL is gradually level, then fill with 0.25 g of the 100 μm asphaltene particles collected above. The test fluids were four drainage samples obtained from agricultural fields. Inject 5mL of drain water into the above-mentioned buret containing glass beads and asphaltene granules, and soak for 24 hours. Afterwards, the filtrate from the buret was titrated and collected. Then add another different drainage sample to the burette as described above. A similar soaking / filtration procedure was repeated five times, resulting in a total of at least 20 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com