Method for efficiently preparing styrene and deuterated styrene compounds

A styrene-based and styrene-substituted technology, applied in the chemical field, can solve the problems of high reaction temperature, harsh reaction conditions, and low efficiency, and achieve the effects of high synthesis efficiency, mild reaction conditions, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

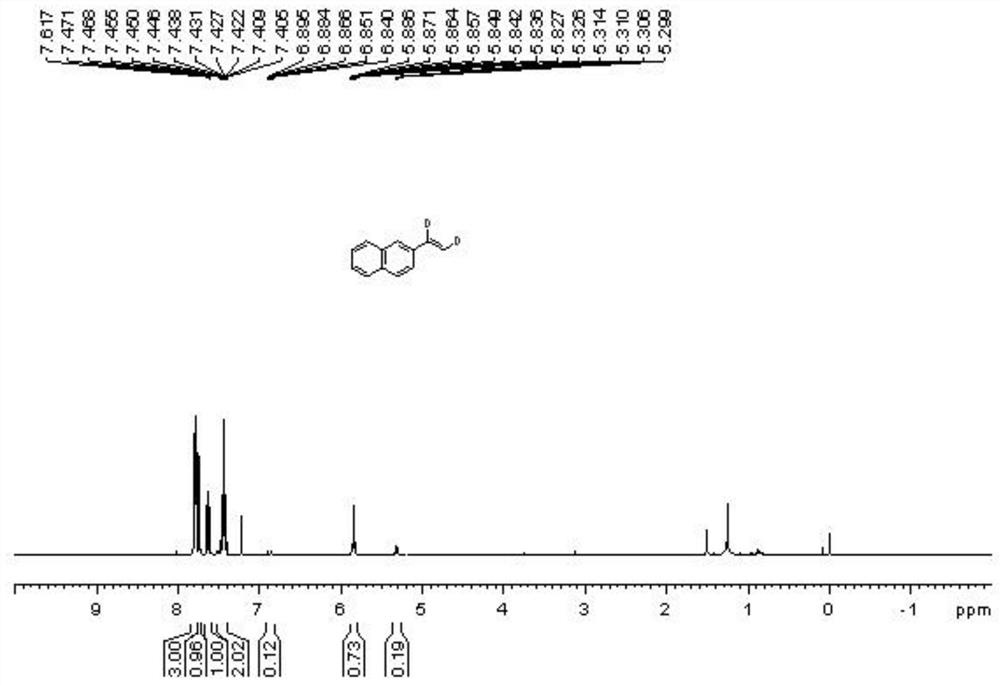

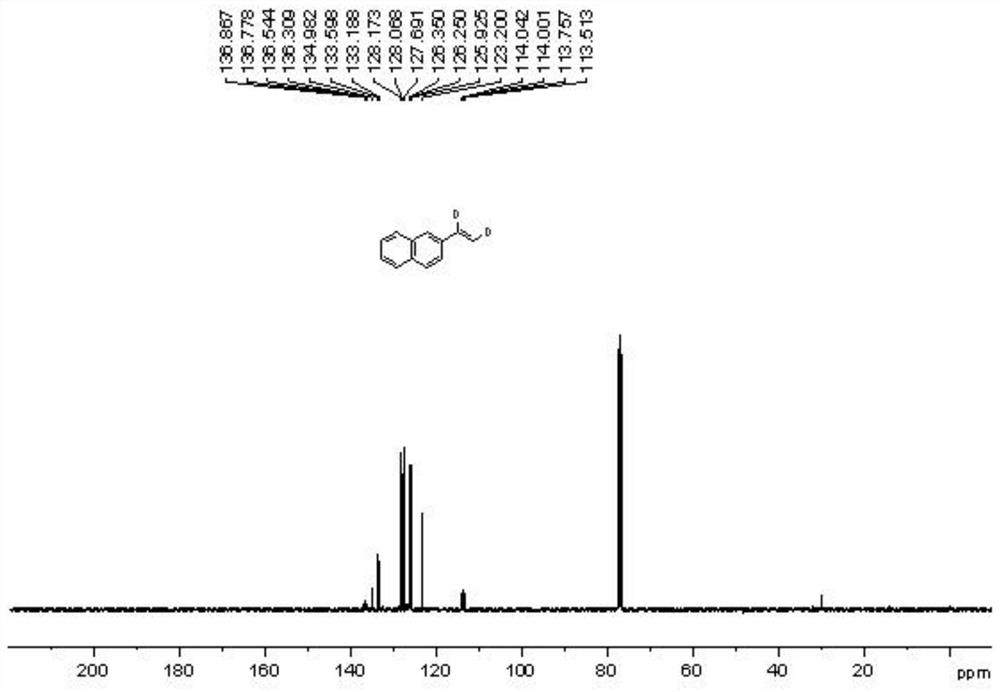

[0038] Zn(OTf) 2 (0.002mmol), Zn (0.6mmol) and phenylacetylene (0.2mmol) were sequentially added to a 10mL reaction tube, then 2ml THF (tetrahydrofuran) was added, and heavy water (0.2mmol) was added and sent out of the glove box. Reaction in an oil bath at 60°C, monitored by TLC and I 2 The reaction process is detected by color development. After the reaction is completed, concentrate and pass through the column with silica gel to obtain the deuterated styrene compound, a colorless liquid, with a yield of 91%, 85% (α), 83% (β) deuterium incorporation rate (according to 1 H NMR spectrum to calculate the deuterium incorporation rate of the compound).

[0039] 1 H NMR (400MHz, CDCl 3 ):δ7.42-7.40(m,2H),7.34-7.30(m,2H),7.26-7.23(m,1H),6.75-6.68(m,0.15H),5.79-5.75(m,1H), 5.25-5.22(m,0.17H).

Embodiment 2

[0041]

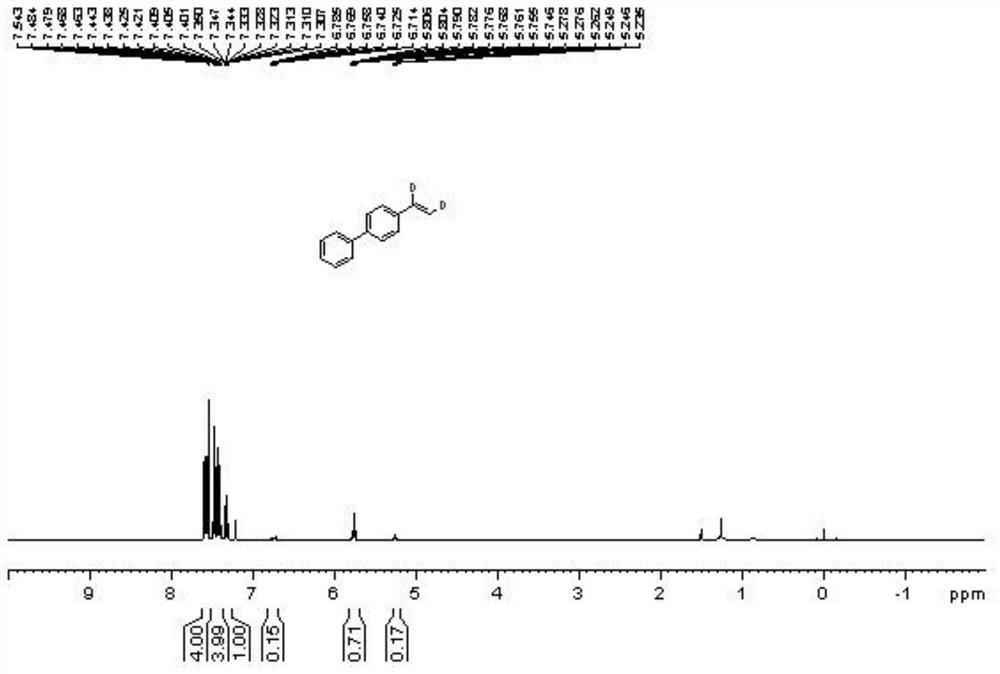

[0042] Zn(OTf) 2 (0.02mmol), Mn (1.0mmol) and 4-methylphenylacetylene (0.2mmol) were sequentially added to a 10mL reaction tube, then 2ml of 1,4-Dioxane, (dioxane) was added, and heavy water (0.5 mmol) were sent out of the glove box. Reaction in an oil bath at 110°C, monitored by TLC and I 2 The reaction process is detected by color development. After the reaction is completed, concentrate and pass through the column with silica gel to obtain the deuterated styrene compound, a colorless liquid, with a yield of 85%, 90% (α), 89% (β) deuterium incorporation rate .

[0043] 1 H NMR (400MHz, CDCl3 ):δ7.37-7.35(m,2H),7.19-7.17(m,2H),6.77-6.70(m,0.10H),5.77–5.72(m,1H),5.27-5.22(m,0.11H) ,2.39(s,3H).

Embodiment 3

[0045]

[0046] In a water-free and oxygen-free glove box under an argon atmosphere, the ZnI 2 (0.2mmol), In (0.1mmol) and 4-chlorophenylacetylene (0.2mmol) were sequentially added to a 10mL reaction tube, then 2ml of tetrahydropyran was added, and heavy water (1.0mmol) was added and sent out of the glove box. Reaction in 70°C oil bath, monitored by TLC and I 2 The reaction process is detected by color development. After the reaction is completed, concentrate and pass through the column with silica gel to obtain the desired product deuterated styrene compound, a colorless liquid, and the yield is 91%, 92% (α), 90% (β) deuterium Incorporation rate.

[0047] 1 H NMR (400MHz, CDCl 3 ):δ7.35-7.28(m,4H),6.71-6.64(m,0.08H),5.78-5.73(m,1H),5.32-5.25(m,0.10H).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap