Waterproof insulation board for constructional engineering

A technology for construction engineering and thermal insulation boards, which is applied in building thermal insulation materials, thermal insulation, building components, etc., can solve the problems of low elasticity, poor fire performance, and high acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of modified phenolic resin specifically comprises the following steps:

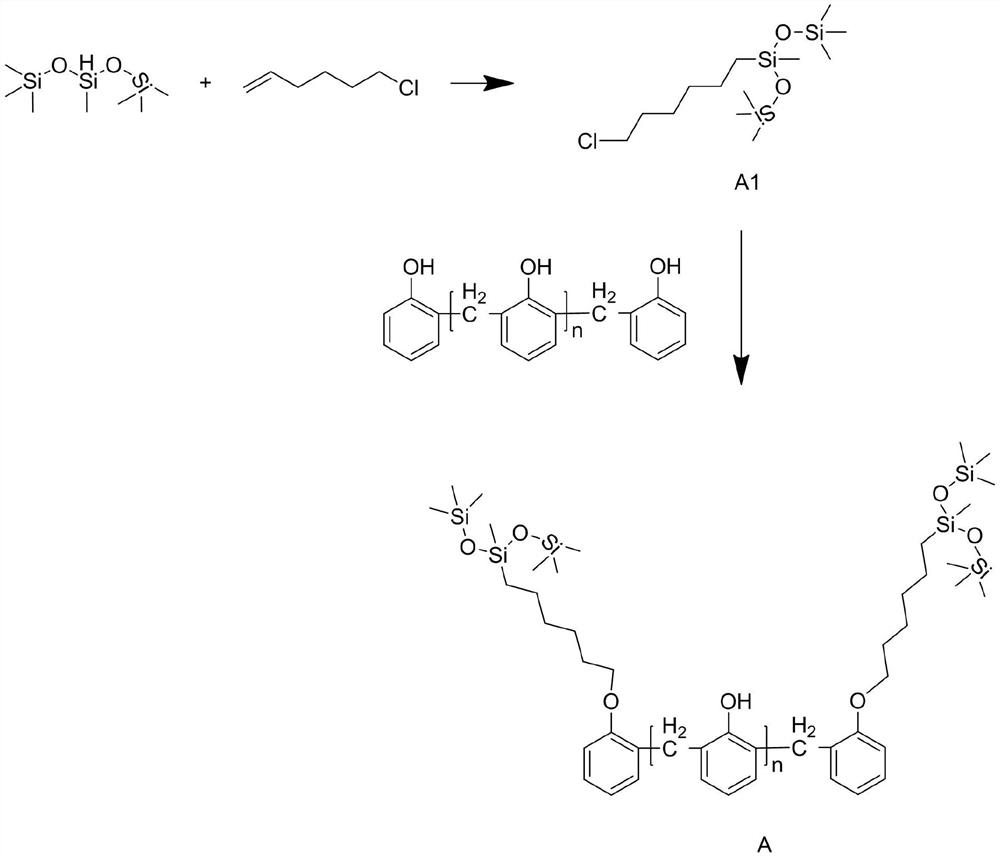

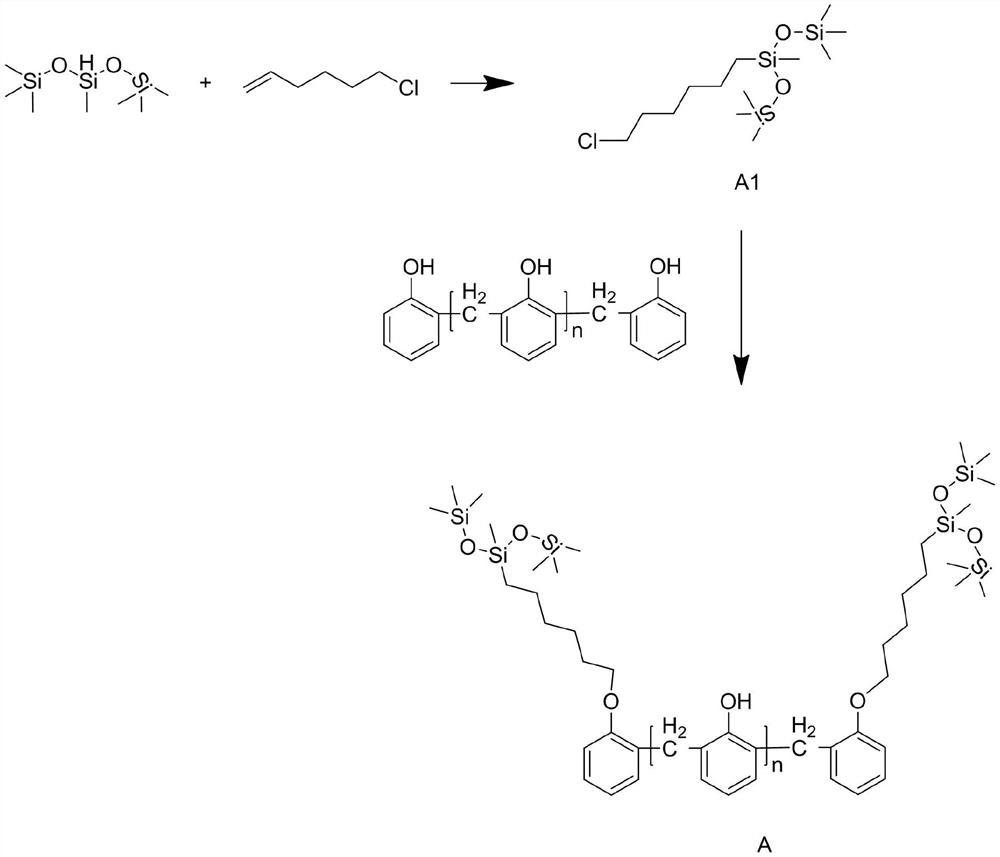

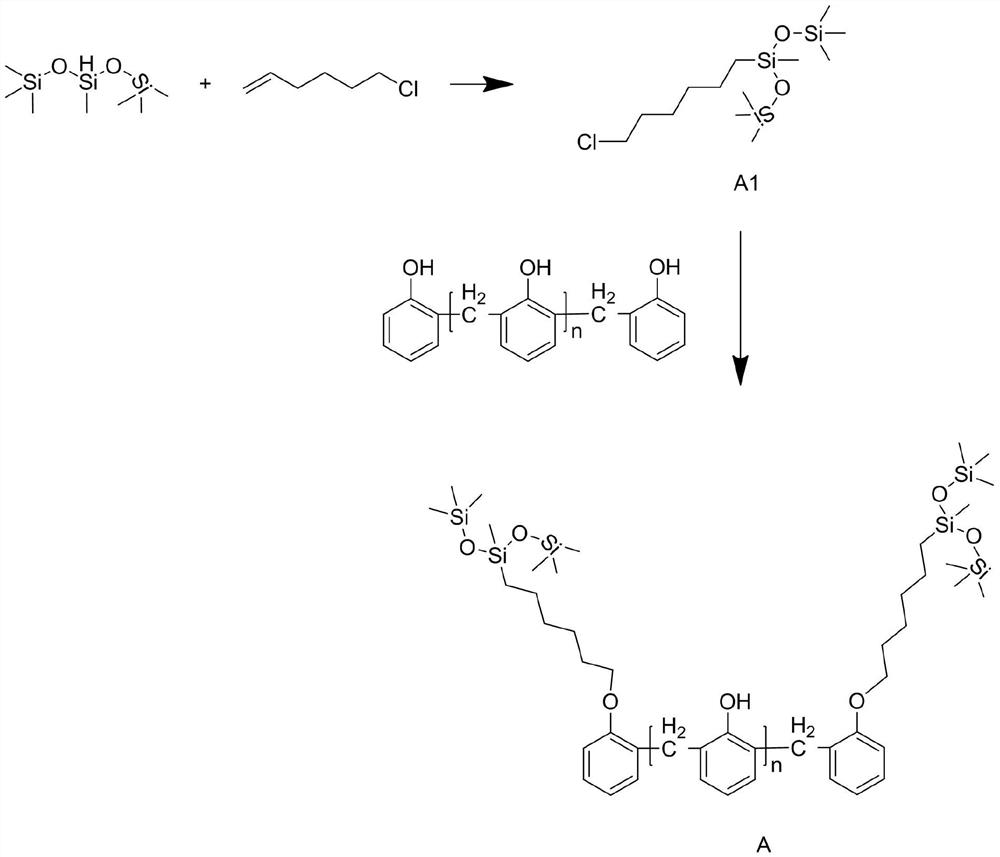

[0025] S1. Preparation of silicon-based modifier

[0026] Weigh 100mmol 1,1,1,3,5,5,5-heptamethyltrisiloxane and 105mmol 6-chloro-1-hexene into the reaction kettle and 600ml of solvent isopropanol, stir and dissolve, pass Into the nitrogen protection, then add 14mmol metal platinum catalyst chloroplatinic acid, continue to pass nitrogen for 15min, until the air in the reactor is completely replaced, turn off the nitrogen, heat up to 80°C while stirring, and carry out the hydrosilylation reaction for 10h. After the reaction, the solvent and unreacted 6-chloro-1-hexene were distilled off under reduced pressure to obtain the silicon-based modifier shown in formula A1;

[0027] S2, preparation of modified phenolic resin

[0028] Weigh 18g of silicon-based modifier A1, 130g of solid phenolic resin powder and 2L of solvent tert-amyl alcohol into the reaction kettle. After stirrin...

Embodiment 2

[0032] A waterproof insulation board for construction engineering, comprising the following raw materials in parts by weight: 80 parts of modified phenolic resin, 25 parts of hollow vitrified microspheres, 16 parts of fly ash, 20 parts of polyacrylate emulsion, 7 parts of polypropylene fiber, 5 parts of sodium carboxymethylcellulose, 5.5 parts of foaming agent, 4.5 parts of surfactant;

[0033] Described whipping agent is n-hexane;

[0034] Described tensio-active agent is sodium dodecylbenzenesulfonate;

[0035] The preparation method of the waterproof insulation board for construction projects is as follows: adding modified phenolic resin, hollow vitrified microspheres, fly ash, polyacrylate emulsion, polypropylene fiber, sodium carboxymethyl cellulose, into a mixing tank Pre-mixing, then put the pre-mixture into the mixer, then add foaming agent and surfactant, stir and mix evenly, raise the temperature to 75°C, keep stirring for 15 minutes, and then pour into molding to o...

Embodiment 3

[0037] A waterproof insulation board for construction engineering, comprising the following raw materials in parts by weight: 100 parts of modified phenolic resin, 30 parts of hollow vitrified microspheres, 14 parts of fly ash, 16 parts of polyacrylate emulsion, 8.5 parts of polypropylene fiber, 6.5 parts of sodium carboxymethylcellulose, 6 parts of foaming agent, 7 parts of surfactant;

[0038] Described whipping agent is n-hexane;

[0039] Described tensio-active agent is sodium dodecylsulfonate;

[0040] The preparation method of the waterproof insulation board for this construction project is: adding modified phenolic resin, hollow vitrified microspheres, fly ash, polyacrylate emulsion, polypropylene fiber, sodium carboxymethyl cellulose, into a mixing tank for Pre-mixing, then put the pre-mixture into the mixer, then add foaming agent and surfactant, stir and mix evenly, raise the temperature to 70°C, keep stirring for 20 minutes, and then pour into molding to obtain a w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap