Silica gel integral open tubular capillary column taking metal wire as template and preparation method thereof

An open-tube capillary column and capillary technology, which is applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of difficult preparation of stationary phase, capillary blockage, uneven distribution of stationary phase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a silica gel integral open-tube capillary column with a metal wire as a template. The preparation method comprises:

[0038] 1) introducing a metal wire into the first capillary as a template, then filling the sol solution into the capillary, and then capping both ends of the first capillary;

[0039] 2) heat-treating the capillary, then performing a temperature-programmed treatment, then removing the template, and then sequentially cleaning, drying and calcining the first capillary to obtain a silica gel integral open-tube capillary column;

[0040] Wherein, the sol solution includes polyethylene glycol, urea, methyl orthosilicate, and acetic acid solution.

[0041] In the above preparation method, the content of each component in the sol solution can be selected in a wide range, but in order to further optimize the shrinkage, mechanical strength and porosity of the stationary phase of the integral open-tube capillary colum...

preparation example 1

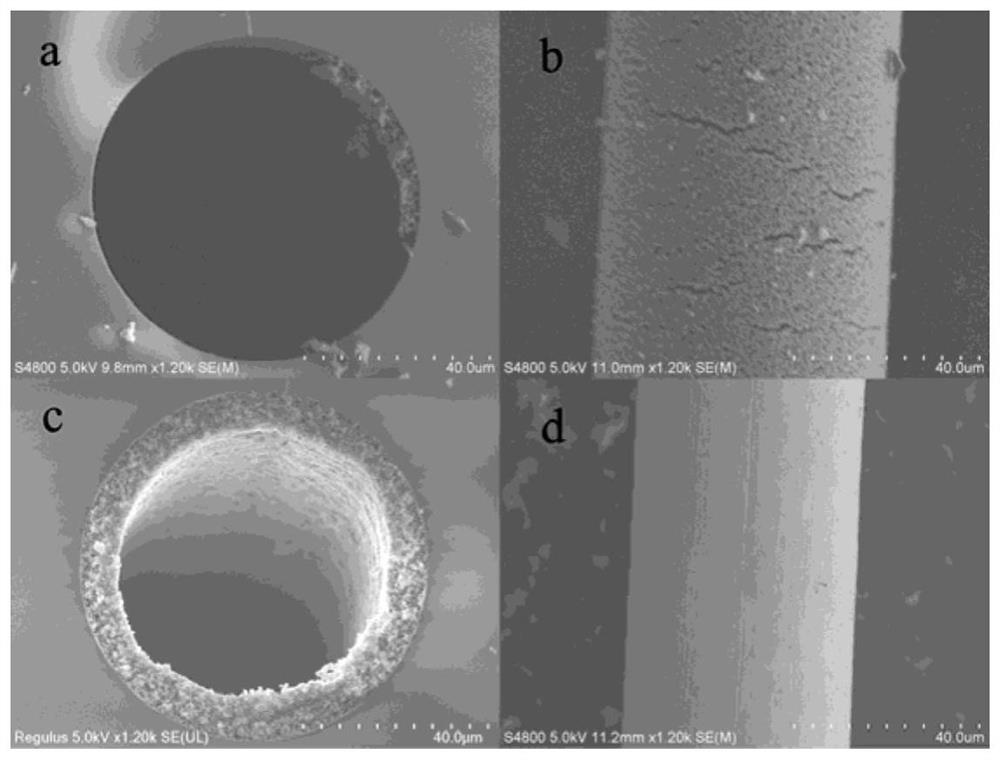

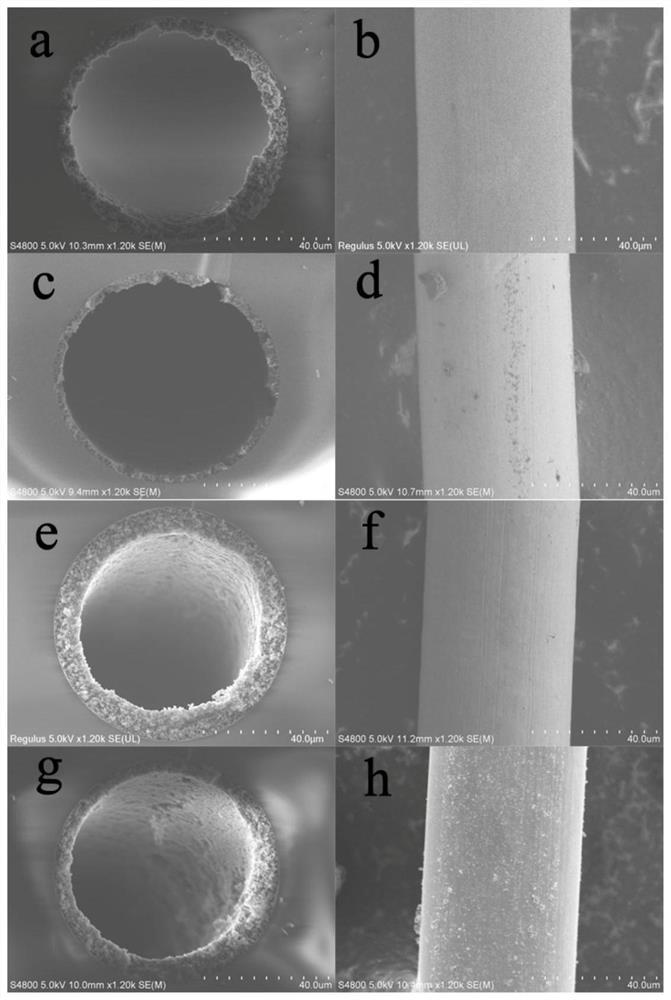

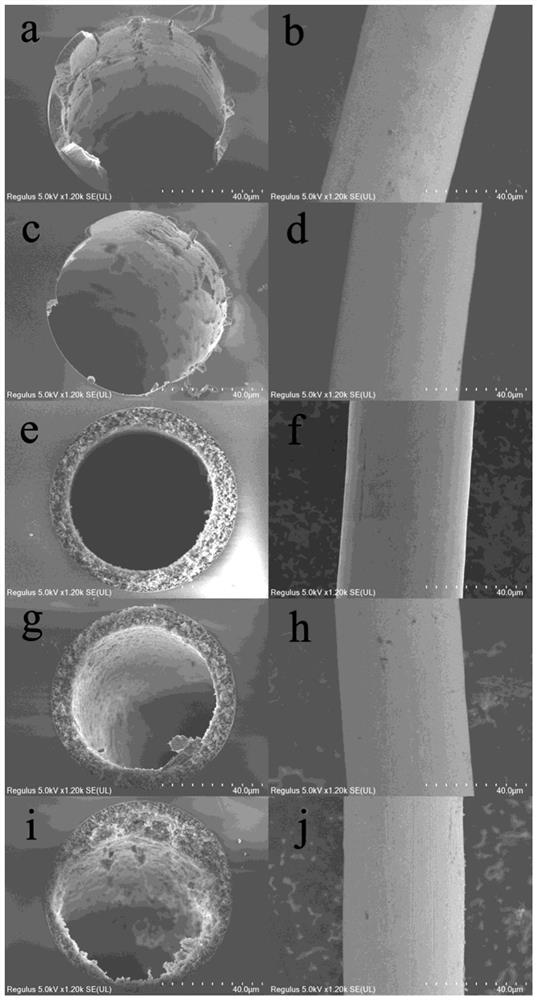

[0068] Such as Figure 12 As shown in a-d of a, place the spotting capillary tubes of various specifications vertically, put a 20 μL pipette tip on the lower end, burn in the middle of the spotting capillary tube, and the glass is heated and softened and pulled down naturally. The inner diameter of the burnt spotting capillary gradually decreases, and the place where the metal filament 4 cannot penetrate is cut off with a capillary cutter to form second capillaries of various specifications.

Embodiment 1

[0070] 1) Dissolve 0.124g PEG-10000 and 0.09g urea in 1mL acetic acid solution (pH 3.4), stir for ten minutes in an ice-water bath, then add 400μL of methyl orthosilicate TMOS, stir for 40min in an ice-water bath, keep Ice-water bath, ice bath, 50KHz ultrasonic conditions vibration 10min degassing.

[0071] Sonicate the metal wire in high-purity water and ethanol for 8-10 minutes, and then dry.

[0072] Wash the capillary of the chromatographic column through sodium hydroxide solution with a concentration of 1 mol / L, hydrochloric acid solution with a concentration of 0.1 mol / L, high-purity water and acetone at 60°C for 5 hours.

[0073] 2) Filter the above sol solution with a 0.45 μm syringe filter, and fill it into a chromatographic column capillary (with an inner diameter of 75 μm and an outer diameter of 365 μm) pierced with a template gold wire (with a diameter of 50 μm).

[0074] After positioning the template (the maximum diameter of the wide mouth end of the second cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com