Conductive silver paste, preparation method and application of conductive silver paste to conductive film

A technology of conductive silver paste and conductive film, which is applied to the equipment used to manufacture conductive/semi-conductive layers, conductive materials dispersed in non-conductive inorganic materials, conductive coatings, etc., can solve the problem of poor tensile properties of conductive films, The surface metal silver is not adsorbed firmly, and the electrical conductivity is reduced, so as to achieve the effect of increasing the binding force, improving the binding performance and good resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

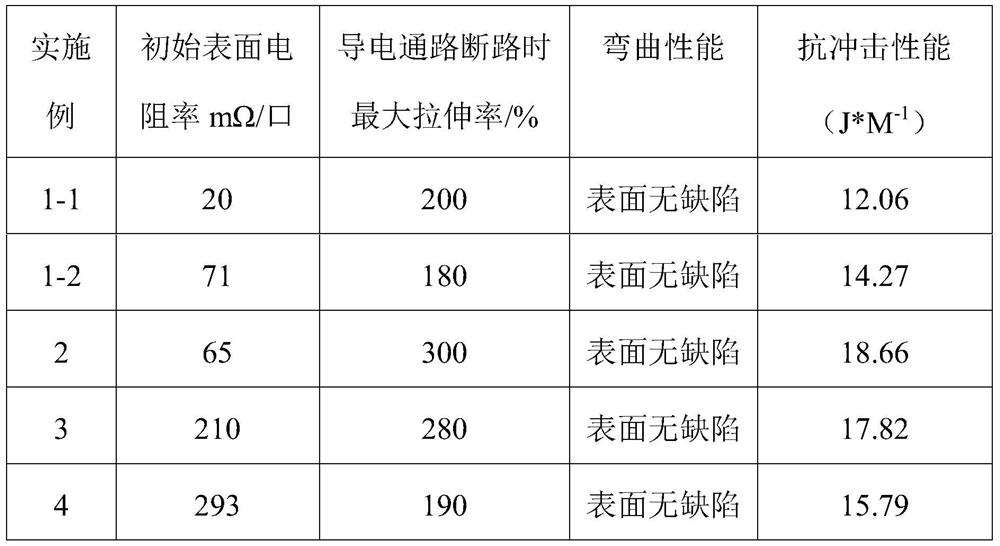

Examples

Embodiment 1

[0036] A kind of conductive silver paste, comprises each component of following mass percentage:

[0037] 69.0% modified metallic silver, the metallic silver is 100% silver powder, the silver powder is a granular powder, wherein the particle size of the silver powder is 0.50 μm-5.00 μm; modified;

[0038] 10.3% silicone resin, wherein the silicone resin includes component A and component B, the mass ratio of the component A to the component B is 2:1, and the component A is dimethyl silicone oil, vinyl silicone oil, ethylene MQ-based silicone resin and platinum catalyst are mixed, and the vinyl silicone oil is a mixture of single-end vinyl silicone oil, double-end vinyl silicone oil, and side-chain vinyl silicone oil in a mass ratio of 1:1:1; the component B is acetylene A mixture of cycloethanol and a cross-linking agent, the cross-linking agent is a mixture of low-hydrogen-containing silicone oil, high-hydrogen-containing silicone oil, and hydrogen-containing MQ silicone res...

Embodiment 2

[0055] A kind of conductive silver paste, comprises each component of following mass percentage:

[0056] 66.7% modified metal silver, the metal silver is composed of 80% silver powder and 20% silver wire, the silver powder is a granular powder, wherein the particle size of the silver powder is 0.5μm-5.00μm, and the diameter of the silver wire is 40nm- 200nm, the silver wire length is 10μm-200μm; metallic silver is modified by sodium dodecylbenzenesulfonate as an anionic surfactant;

[0057] 11.1% silicone resin, wherein the silicone resin includes component A and component B, the mass ratio of the component A to the component B is 1:1, and the component A is dimethyl silicone oil, vinyl silicone oil, ethylene MQ-based silicone resin and platinum-palladium catalyst are mixed, and the vinyl silicone oil is mixed with single-end vinyl silicone oil, double-end vinyl silicone oil, and side-chain vinyl silicone oil in a mass ratio of 1:1:1; the component B is A mixture of ethynyl ...

Embodiment 3

[0071] A kind of conductive silver paste, comprises each component of following mass percentage:

[0072]51.9% modified metal silver, the metal silver is composed of 95% silver powder and 5% silver wire, the silver powder is a granular powder, wherein the particle size of the silver powder is 0.5μm-5.00μm, and the diameter of the silver wire is 40nm- 200nm, the length of the silver wire is 10μm-200μm; metal silver is modified with stearic acid as an anionic surfactant;

[0073] 13.0% silicone resin, wherein the silicone resin includes component A and component B, the mass ratio of the component A to the component B is 1:1, and the component A is dimethyl silicone oil, vinyl silicone oil, ethylene MQ-based silicone resin and platinum catalyst are mixed, and the vinyl silicone oil is a mixture of single-end vinyl silicone oil, double-end vinyl silicone oil, and side-chain vinyl silicone oil in a mass ratio of 1:1:1; the component B is acetylene A mixture of cycloethanol and a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com