Application of dithiocarbamic acid compound in electroless palladium plating and electroless palladium plating composition

A dithiocarbamic acid and chemical plating technology, applied in the field of chemical plating, can solve problems such as unfavorable productivity increase, affecting production line productivity, raising the temperature of an electroless palladium plating solution, etc., to achieve the effects of increasing deposition speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

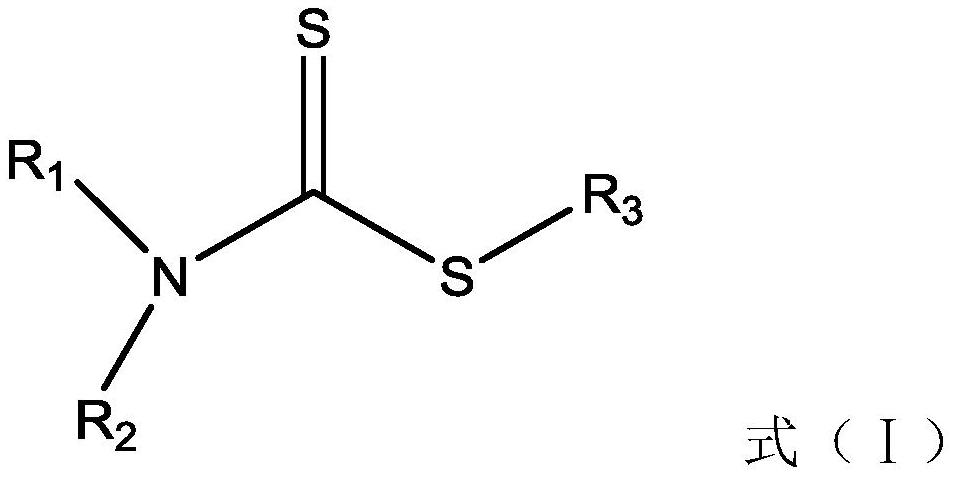

[0057] In a specific example, the preparation method of the electroless palladium plating composition comprises the following steps: calculate the consumption of each raw material of the composition according to the preset volume; add the palladium source into the solvent for dissolution; add complexing agent, reducing agent and A dithiocarbamate compound with a structure represented by formula (I); the pH of the composition is adjusted to 4-9.

[0058] Preferably, the preparation method of the electroless palladium plating composition is: calculate the amount of each raw material of the composition according to the preset volume; add the palladium source into the solvent for dissolution; add complexing agent, reducing agent and The structural dithiocarbamic acid compound; the pH of the composition is adjusted to 4-9.

[0059]As a specific example, the preparation method of the electroless palladium plating composition is as follows: pure water is used as a solvent, and the pr...

Embodiment 1

[0073] The dithiocarbamic acid compound in this implementation is S-(N,N-dimethylthiocarbamoyl)thioglycolic acid (CAS number: 4007-01-6). The preset volume of the electroless palladium plating composition in this embodiment is 2L. Based on 2L, each raw material in the composition is 100mg / L palladium chloride, 5g / L ethylenediamine, 1g / L sodium hypophosphite and 0.1mg / L S-(N,N-dimethylthiocarbamate Acyl) thioglycolic acid, the solvent is pure water.

[0074] The preparation method of the electroless palladium plating composition in the present embodiment is: add pure water in beaker, palladium chloride is dissolved in pure water, then add ethylenediamine, sodium hypophosphite and S-(N,N-di Methylthiocarbamoyl) mercaptoacetic acid, adjust solution pH=4 with hydrochloric acid, the volume of electroless palladium plating composition is 2L, standby.

Embodiment 2

[0076] The dithiocarbamate compound in this implementation is butyl ethyl dithiocarbamate (CAS number: 83962-20-3). The preset volume of the electroless palladium plating composition in this embodiment is 2L. Based on 2L, the raw materials in the composition are 700mg / L palladium sulfate, 30g / L ethylenediaminetetraacetic acid, 15g / L sodium formate and 10mg / L butyl ethyl dithiocarbamate, and the solvent is pure water.

[0077] The preparation method of the electroless palladium plating composition in this embodiment is: add pure water in the beaker, dissolve palladium sulfate in pure water, then add ethylenediaminetetraacetic acid, sodium formate and butyl ethyldithiocarbamate successively , the pH of the solution was adjusted to 6.5 with sulfuric acid, the volume of the electroless palladium plating composition was 2L, and it was set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com