Egg polypeptide preparation method and egg polypeptide beverage

A technology of polypeptide powder and egg yolk, which is applied in the field of egg polypeptide preparation, can solve the problems affecting the quality of egg polypeptide products, and achieve the effects of good anti-oxidation function, increased enzymatic hydrolysis efficiency, and low bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An egg polypeptide beverage, its raw material components are:

[0029] Deionized water 100g, egg polypeptide powder 3g, milk 10g, honey 9g, citric acid 0.5g, xanthan gum 0.15g, carboxymethylcellulose sodium 0.15g, sucrose ester 0.01g.

[0030] Its production steps include:

[0031] Step 1, preparation of egg polypeptide powder:

[0032] S1. Take 210g of egg white powder, add 1000g of deionized water and stir evenly to obtain protein solution 1; microwave the protein solution 1 at a microwave power of 90W for 30s, and then ultrasonicate at an ultrasonic frequency of 20kHz and an ultrasonic power of 420W. 10min, obtain the protein solution 2 after pretreatment;

[0033] S2. Add 12 g of alkaline protease to the protein solution 2, stir evenly to obtain a mixed solution 1, adjust the pH of the mixed solution 1 to 8.6 with a phosphate buffer solution, adjust the temperature to 52° C., shake and hydrolyze for 50 minutes, Then raise the temperature to 92°C, keep the tempera...

Embodiment 2

[0045] An egg polypeptide beverage, its raw material components are:

[0046] Deionized water 100g, egg polypeptide powder 3g, milk 10g, honey 9g, citric acid 0.5g, xanthan gum 0.15g, carboxymethylcellulose sodium 0.15g, sucrose ester 0.01g.

[0047] Its production steps include:

[0048] Step 1, preparation of egg polypeptide powder:

[0049] S1. Take 210g of egg yolk water-soluble protein powder, add 1000g of deionized water and stir evenly to obtain protein solution 1; microwave the protein solution 1 at a microwave power of 90W for 30s, and then at an ultrasonic frequency of 20kHz and an ultrasonic power of 420W. Ultrasound for 10 minutes to obtain the pretreated protein solution 2;

[0050] S2. Add 12 g of alkaline protease to the protein solution 2, stir evenly to obtain a mixed solution 1, adjust the pH of the mixed solution 1 to 8.6 with a phosphate buffer solution, adjust the temperature to 52° C., shake and hydrolyze for 50 minutes, Then raise the temperature to 9...

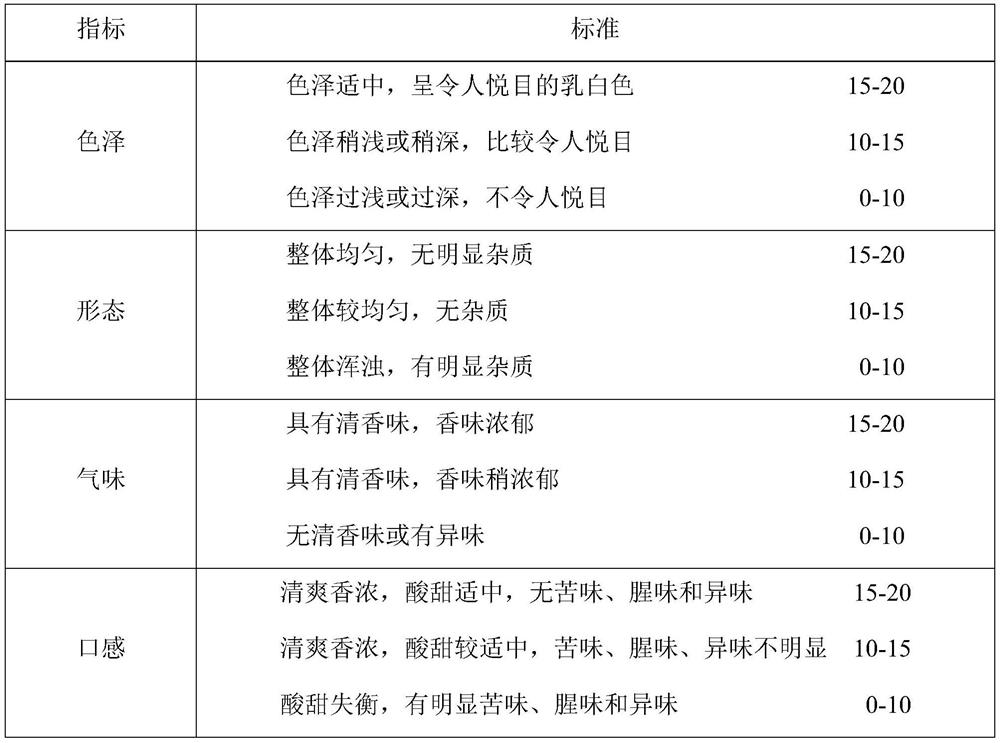

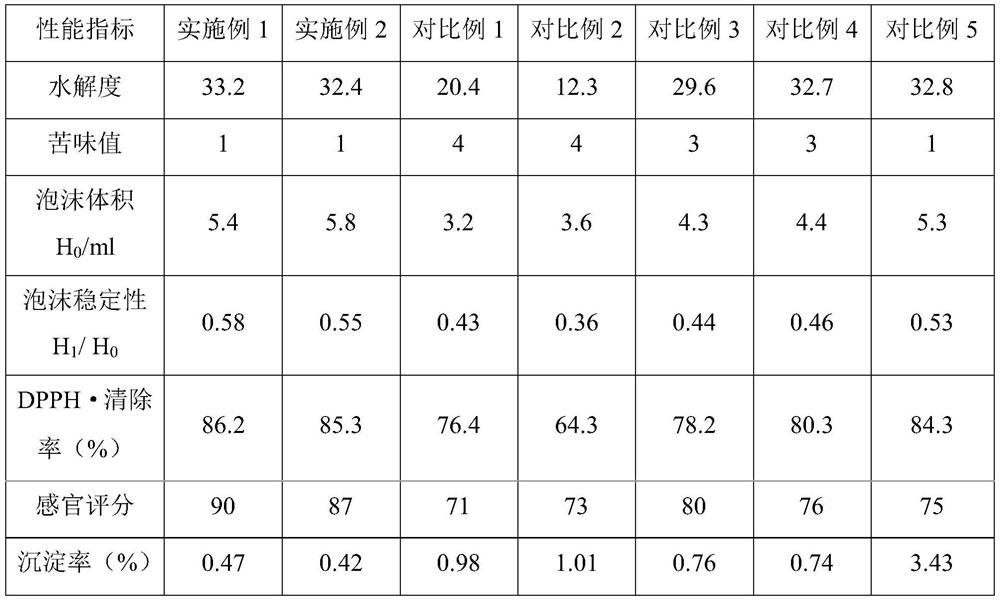

experiment example

[0075] 1. Determination of degree of hydrolysis

[0076] The method used: using double indicator formaldehyde titration

[0077] Degree of hydrolysis (%) = (amount of amino nitrogen generated after hydrolysis / total nitrogen content in the sample) × 100%

[0078] Determination of total nitrogen content: using the Kjeldahl method;

[0079] Determination of the amount of amino nitrogen:

[0080] (1) Phenolphthalein indicator: 0.5g phenolphthalein is dissolved in 100ml 50% ethanol to obtain 0.5% phenolphthalein;

[0081] (2) Neutral formaldehyde solution: formaldehyde solution (36-37%, analytically pure) 50ml, add about 3ml of 0.5% phenolphthalein indicator, add dropwise 0.1mol / L sodium hydroxide, make the solution microscopically pink, store in brown In the bottle, prepare before use;

[0082] (3) Determination of amino nitrogen: absorb 2ml of hydrolyzed solution, add 5ml of deionized water to a beaker, add 5 drops of phenolphthalein indicator to the beaker, add 2.0ml of neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com