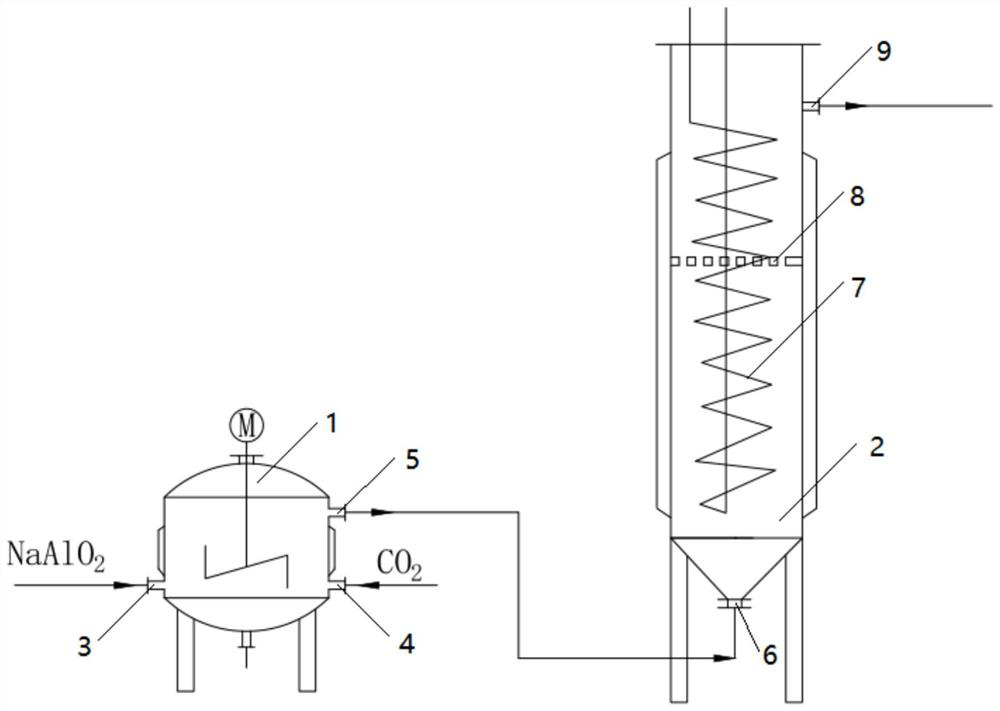

A system for continuous production of pseudo-boehmite and using method thereof

A pseudo-boehmite and sodium aluminate technology, which is applied in the field of continuous production of pseudo-boehmite, can solve problems such as poor product quality stability, broken decomposition towers, mixed flow of decomposition reactions, etc., to achieve stable and product quality quality, keeping the burn reduction unchanged, and purifying the site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

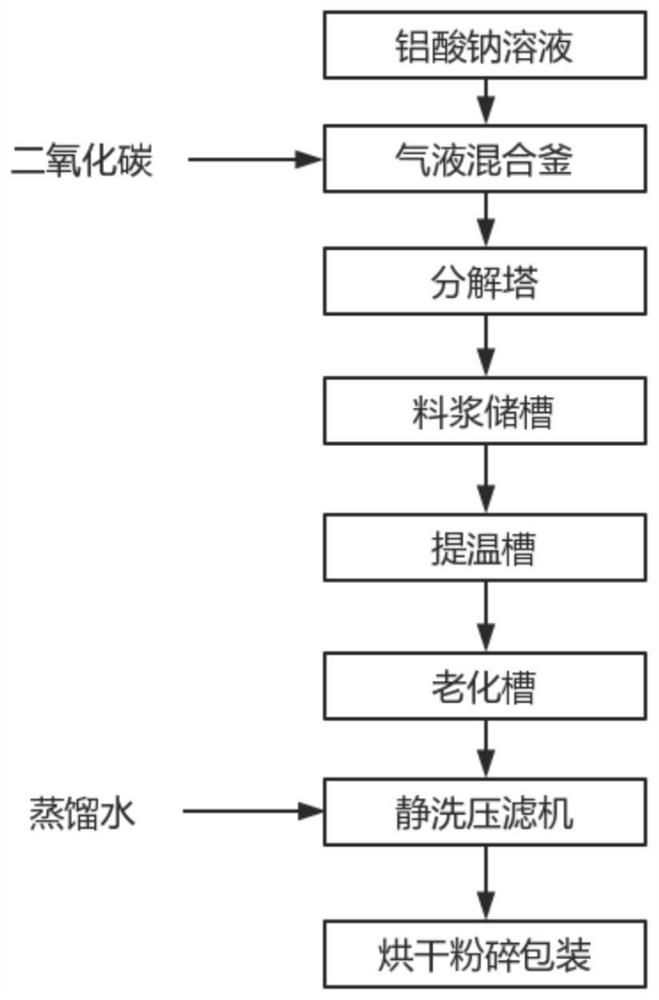

Method used

Image

Examples

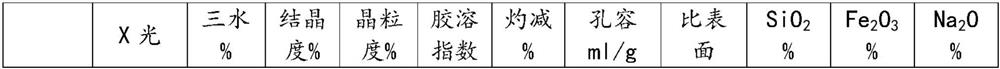

Embodiment 1

[0085] Prepare sodium aluminate solution 12L, alumina concentration 40g / l, ventilation speed 1.5m 3 / h, install the reaction device, use a peristaltic pump to measure the feeding rate of the sodium aluminate solution during continuous feeding, first add 1.0 L of sodium aluminate solution into the decomposition tower, measure the initial temperature of the sodium aluminate solution at 15°C, and start to open Intake valve, carry out pre-decomposition, at this moment peristaltic pump does not open, ventilation time is 12min, when pre-decomposition ends, open peristaltic pump and start to feed sodium aluminate solution, peristaltic pump feed rate 20, after 5min, the storage tank of decomposition tower The overflow port begins to overflow with slurry, enters the slurry storage tank, overflows naturally after 30 minutes, and directly enters the temperature raising tank with a pipeline, and starts to raise the temperature. After reaching the temperature, it is naturally transferred t...

Embodiment 2

[0091] Prepare sodium aluminate solution 20L, alumina concentration 50g / l, ventilation speed 2.5m 3 / h, install the reaction device, use the peristaltic pump to measure the feeding rate of the sodium aluminate solution during continuous feeding, first add 1.5L of the sodium aluminate solution into the decomposition tower, measure the initial temperature of the sodium aluminate solution, and keep the initial temperature at 30 ℃, start to open the air inlet valve, carry out pre-decomposition, now the peristaltic pump does not open, ventilation time 20min time, when the pre-decomposition ends, open the peristaltic pump and start to enter the sodium aluminate solution, the peristaltic pump feed rate 30, after 3min, decompose The overflow port of the storage tank of the tower begins to overflow with slurry. After entering the slurry storage tank for 40 minutes, the slurry overflows. It is directly passed into the temperature raising tank with a pipeline, and the temperature is raise...

Embodiment 3

[0096] Prepare sodium aluminate solution 300L, alumina concentration 40g / l, ventilation speed 2.0m 3 / h, this example was prepared and implemented according to the continuous reaction of 72 hours, the reaction device was installed, the feeding rate of the sodium aluminate solution during continuous feeding was measured with a peristaltic pump, and 1.5L of sodium aluminate solution was first added into the decomposition tower. The initial temperature of the sodium aluminate solution, the initial temperature is kept at 20 ℃, the intake valve is opened, and the pre-decomposition is carried out. At this time, the peristaltic pump is not turned on, and the ventilation time is 22 minutes. When the pre-decomposition is over, the peristaltic pump is turned on to start the sodium aluminate solution. , the feed rate of the peristaltic pump is 30 rpm, after 3 minutes, the overflow port of the storage tank of the decomposition tower begins to overflow with slurry, and after entering the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com