Modified polyurea and its application

A modification and raw material technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problem of poor color retention and UV resistance, inability to be flexibly used in small scales, and poor substrate material wettability, etc. problems, to achieve the effect of simple and convenient construction operation, prolonging the construction time limit, and increasing the construction time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

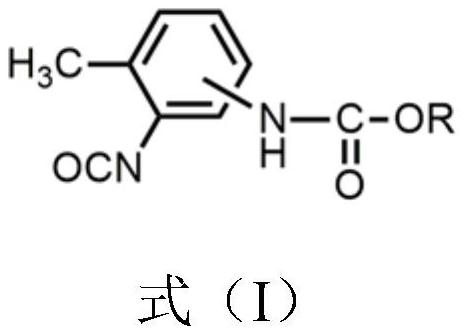

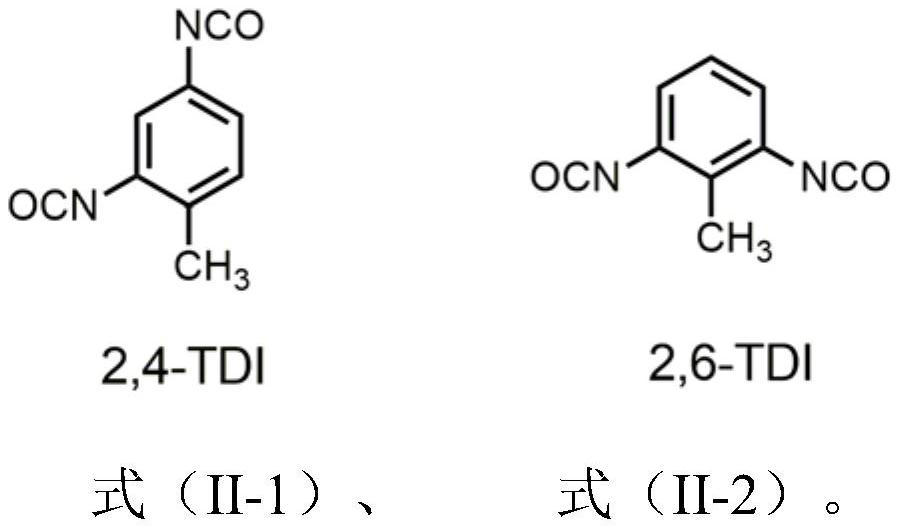

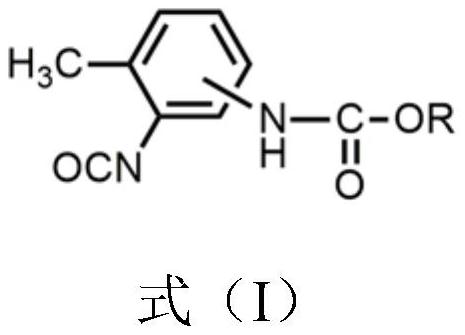

[0067] In one of the embodiments, the preparation method of the monofunctional isocyanate comprises the following steps:

[0068] Mix the toluene diisocyanate, auxiliary agents and aliphatic unit alcohols for reaction, and stop the reaction when the -NCO content in the system is less than 15%.

[0069] In one embodiment, the temperature of the reaction is 40°C-60°C, and the reaction time is 6h-10h.

[0070] In one of the embodiments, the auxiliary agent includes an antioxidant;

[0071] The amount of the antioxidant added is 0.05% to 0.15% by mass of the total mass of raw materials for preparing the monofunctional isocyanate.

[0072] In one of the embodiments, the antioxidant is 2,6-di-tert-butyl-p-methylphenol, also known as 2,6-di-tert-butyl-4-methyl-phenol, or 3,5 -3,5-di-tert-butyl-4-hydroxytoluene, hereinafter abbreviated as BHT-264.

[0073] In one of the embodiments, the auxiliary agent also includes a solvent;

[0074] The solvent is at least one selected from est...

Embodiment 1

[0095] This embodiment provides a modified polyurea and its application.

[0096] (1) Preparation of monofunctional isocyanate 1

[0097] Put 174.16g (1 mole) of T-100, 130.22g (1 mole) of isooctyl alcohol, 34g of butyl acetate and 2g of BHT-264 into the reaction kettle, blow nitrogen gas, and raise the temperature to 40°C~42°C , reacted for 6 hours, when the NCO% was 12.3%, cooled to room temperature, filtered and packaged to obtain monofunctional isocyanate 1, the performance results are shown in Table 1.

[0098] (2) Preparation of modified polyurea 1

[0099] Mix monofunctional isocyanate 1 and F520 polyaspartic acid ester resin at a molar ratio of -NCO: -NH of 1:1, and stir evenly to obtain modified polyurea 1. The performance results are shown in Table 2.

Embodiment 2

[0101] This embodiment provides a modified polyurea and its application.

[0102] (1) Preparation of monofunctional isocyanate 2

[0103] Put 174.16g (1 mole) of T-80, 16g of butyl acetate and 3g of BHT-264 into the reactor, blow nitrogen, heat up to 58°C to 60°C, and drop 130.22g (1 mol) of isooctyl alcohol is added for 2 hours. After the dropwise addition, react at 58°C to 60°C for 4 hours. When the NCO% is 13.0%, cool down to room temperature, filter and package to obtain monofunctional isocyanate 2. The performance results are shown in Table 1.

[0104] (2) Preparation of modified polyurea 2

[0105] Mix monofunctional isocyanate 2 and F520 polyaspartic acid ester resin at a molar ratio of -NCO: -NH of 1:1, and stir evenly to obtain modified polyurea 2. The performance results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com