Copolymerized polyamide capable of producing ferroelectric nylon film by simple thermal processing and preparation method thereof

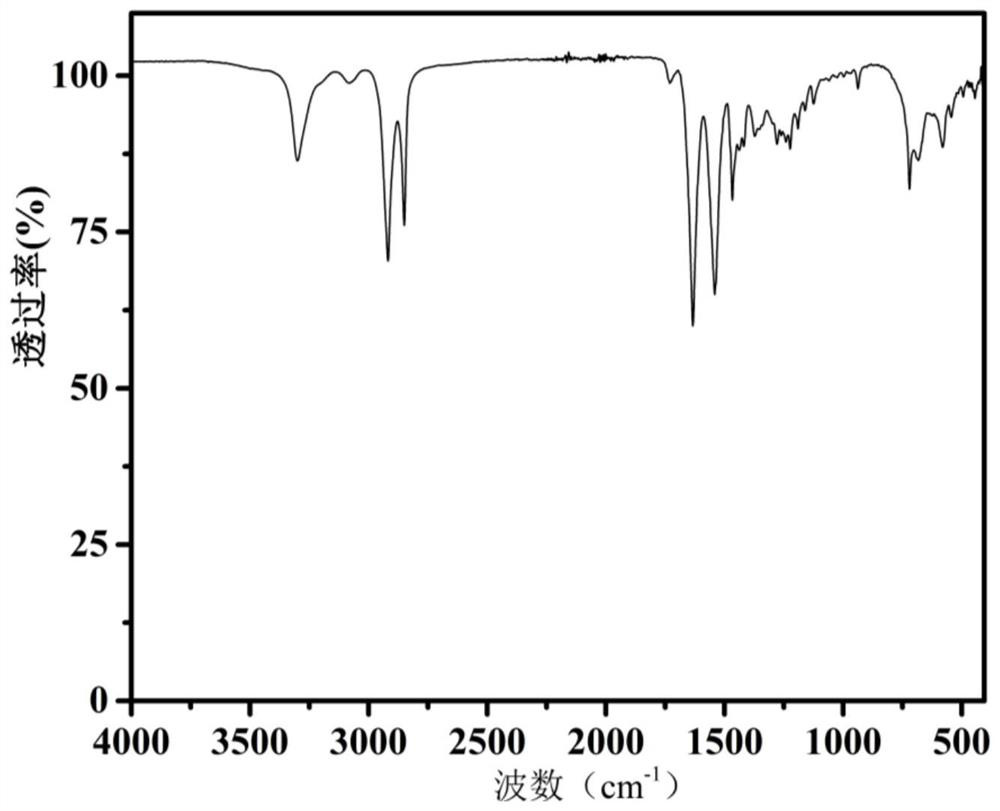

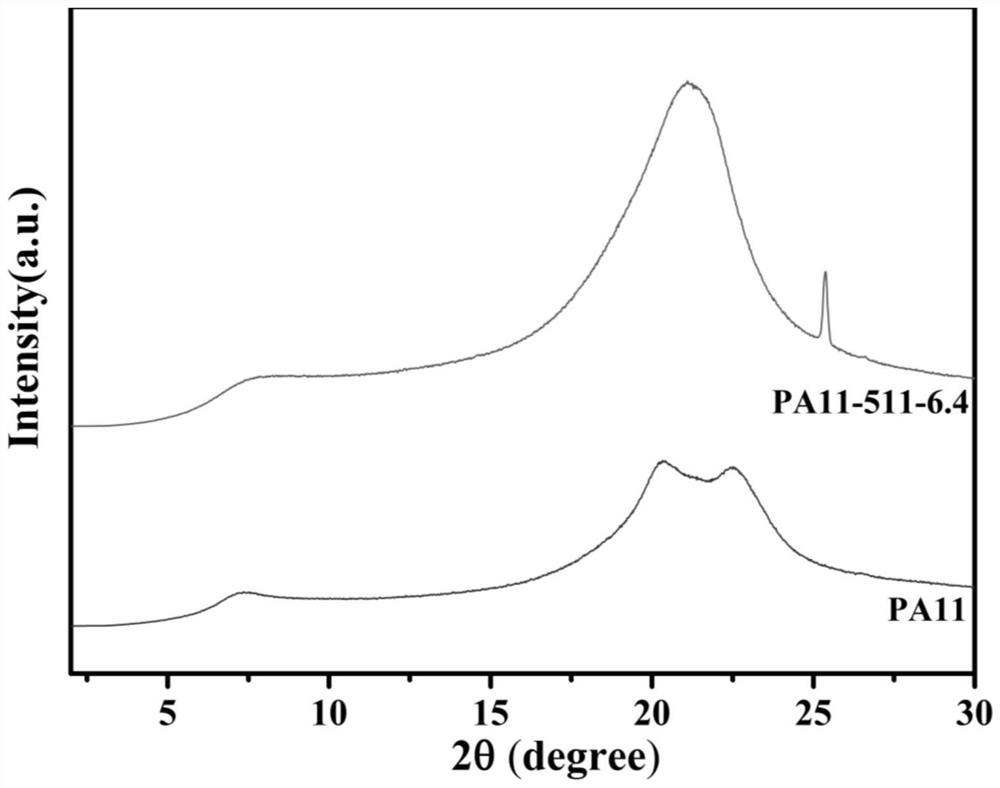

A technology for copolymerizing polyamide and nylon films, which is applied to the synthesis field of ferroelectric polyamides, can solve the problems of difficulty in large-scale, continuous and rapid preparation of ferroelectric nylon films, and difficulty in obtaining ferroelectric crystals, and achieves easy processing and ferroelectricity. The effect of stable crystal form and adjustable melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a ferroelectric nylon film (PA11511-9.1 for short) that can be obtained by simple thermal processing:

[0042] Step 1: Preparation of nylon 511 salt, weigh 54g of undecanedioic acid (about 0.25mol), 25.75g (about 0.25mol) of pentamethylenediamine and 200ml of deionized water in proportion, mix well and pour it into 500ml three wells in the flask. Turn on the stirring device and set the rotational speed to 60 r / min, and introduce nitrogen to replace the air in the three-necked flask. The temperature was raised to 80°C to carry out the salt-forming reaction, and the pH of the system was adjusted to 7.2 by adding a small amount of reactants. The reaction was stopped after 1 hour of normal pressure reaction. The aqueous solution of the obtained nylon 511 salt was subjected to rotary evaporation, and then the product was dried under vacuum at 80° C. for 4 hours to obtain the nylon 511 salt as a white powder, ready for use.

[0043] Step 2: Pre-poly...

Embodiment 2

[0047] A preparation method of a ferroelectric nylon film (PA11511-8.2 for short) that can be obtained by simple thermal processing:

[0048] Step 1: Preparation of nylon 511 salt, weigh 54g of undecanedioic acid (about 0.25mol), 25.75g (about 0.25mol) of pentamethylenediamine and 200ml of deionized water in proportion, mix well and pour it into 500ml three wells in the flask. Turn on the stirring device and set the rotational speed to 60 r / min, and introduce nitrogen to replace the air in the three-necked flask. The temperature was raised to 80°C to carry out the salt-forming reaction, and the pH of the system was adjusted to 7.2 by adding a small amount of reactants. The reaction was stopped after 1 hour of normal pressure reaction. The obtained aqueous solution of nylon 511 salt was subjected to rotary evaporation, and then the product was dried under vacuum at 80° C. for 4 hours to obtain a white powder of nylon 511 salt, which was ready for use.

[0049] Step 2: Pre-po...

Embodiment 3

[0052] A preparation method of a ferroelectric nylon film (PA11511-7.3 for short) that can be obtained by simple thermal processing:

[0053] Step 1: Preparation of nylon 511 salt, weigh 54g of undecanedioic acid (about 0.25mol), 25.75g (about 0.25mol) of pentamethylenediamine and 200ml of deionized water in proportion, mix well and pour it into 500ml three wells in the flask. Turn on the stirring device and set the rotational speed to 60 r / min, and introduce nitrogen to replace the air in the three-necked flask. The temperature was raised to 80°C to carry out the salt-forming reaction, and the pH of the system was adjusted to 7.2 by adding a small amount of reactants. The reaction was stopped after 1 hour of normal pressure reaction. The obtained aqueous solution of nylon 511 salt was subjected to rotary evaporation, and then the product was dried under vacuum at 80° C. for 4 hours to obtain a white powder of nylon 511 salt, which was ready for use.

[0054] Step 2: Pre-po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

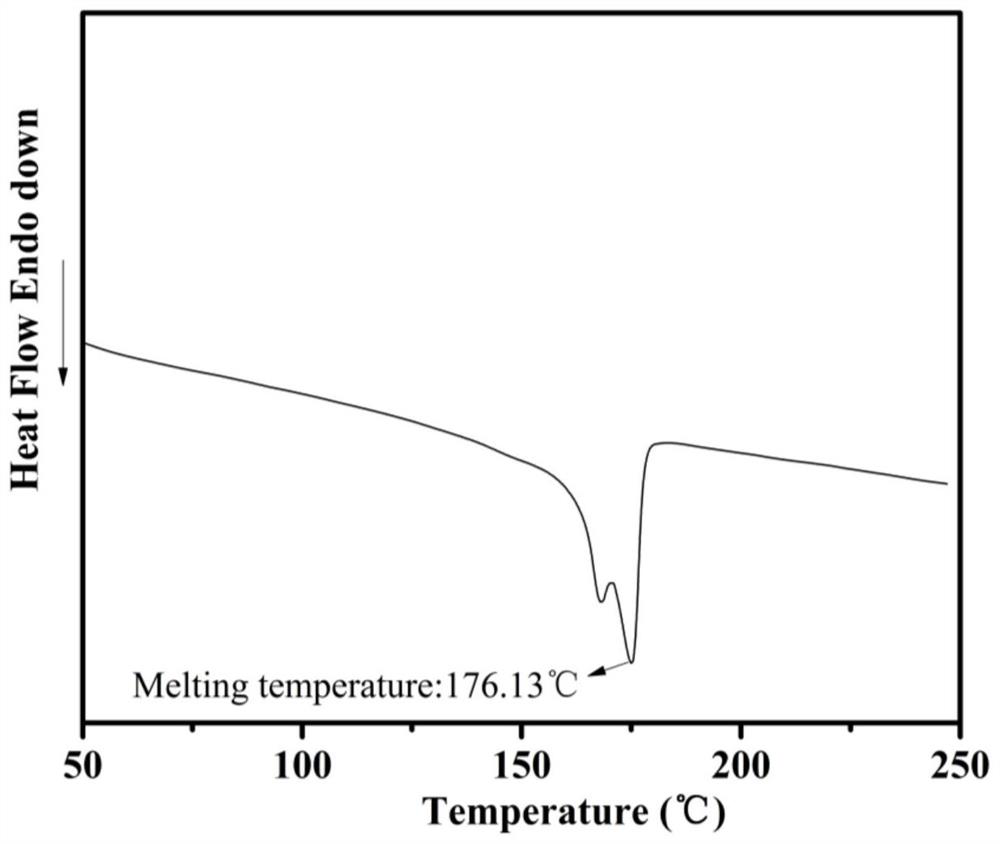

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com