Polymerized ultraviolet absorbent, acrylic resin, and preparation method of modified epoxy coating

An ultraviolet absorber and acrylic resin technology, applied in the field of coatings, can solve problems such as failure and poor epoxy aging resistance, and achieve the effects of good light aging resistance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

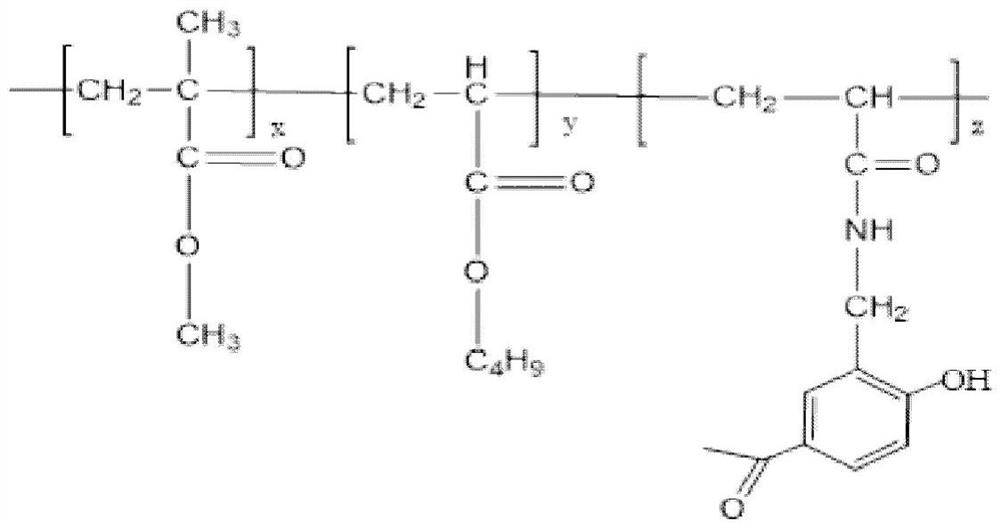

[0023] On the one hand, the invention provides a kind of preparation method of polymeric ultraviolet absorber, comprises the following steps:

[0024] 4-hydroxybenzophenone, N-methylolacrylamide, organic solvent and anhydrous aluminum chloride are mixed and reacted in a constant temperature water bath, and then purified by column chromatography to obtain a polymeric ultraviolet absorber. The polymeric ultraviolet absorber Including 3-acrylamidomethyl-4-hydroxybenzophenone, the 3-acrylamidomethyl-4-hydroxybenzophenone has a carbon-carbon double bond functional group.

[0025] In some of the embodiments, the organic solvent is acetone and / or dichloromethane, and the reaction temperature in the constant temperature water bath is 35-40°C.

[0026] It can be understood that the present invention mixes 4-hydroxybenzophenone and N-hydroxyacrylamide, reacts with acetone or dichloromethane as a solvent, and uses aluminum trichloride as a catalyst to obtain the desired compound 3 throug...

Embodiment

[0042] Preparation of polymeric UV absorber:

[0043] Add 4-hydroxybenzophenone, N-methylolacrylamide and an appropriate amount of dichloromethane into a three-necked flask equipped with an electric stirring device, place it in a constant temperature water bath at 35°C to stir and react, condense and reflux, and wait for the raw materials to After dissolving, a 6% mass fraction of anhydrous aluminum chloride in dichloromethane solution was slowly added dropwise, and after reaction, purified by column chromatography to obtain a polymeric ultraviolet absorber.

[0044] Preparation of acrylic resin based on the polymeric UV absorber:

[0045](1) The mass ratio is (20%-50%): (15%-35%): (2%-10%): (5%-15%): (1%-5%): (1% -5%) of methyl methacrylate, BA, target compound, solvent, catalyst and chain transfer agent are mixed and added to a three-necked flask equipped with an electric stirring device, the oil bath is heated to 80°C-110°C, and the reaction is condensed while stirring Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com