Use of mulberry extract in preparation of medicine for treating abnormal glycolipid metabolism in mammals

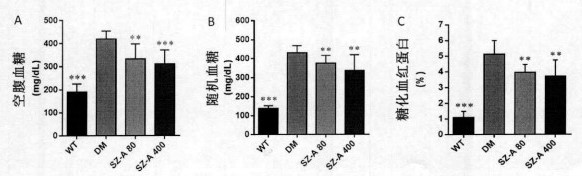

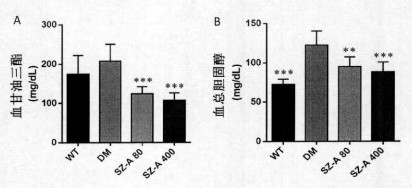

A technology for mammalian and glycolipid metabolism, which is applied in the field of use of mulberry extract in the preparation of medicines for treating abnormal glucose and lipid metabolism in mammals, and can solve the problem of rarely reported drug effects, inability to reflect the role of genetic factors, and model individuals. problems such as large differences, to achieve good therapeutic effects, small individual differences, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0027]Take 1000kg of fresh mulberry branches (Yuesang No. 11), crush them, add 4000L of water, extract by heating and reflux for 2 hours, combine the extracts, filter to remove insoluble matter, and obtain a crude extract. The crude extract was thermally concentrated until the solid content reached 4%, and was used as the sample solution for the cationic resin column.

[0028] Use 150kg of D113 type macroporous weakly acidic styrene-acrylic cationic resin to pack the column, use 2mol / L hydrochloric acid solution to wash until the pH of the eluate is 4.5; use 1mol / L sodium hydroxide solution to wash until the pH of the eluate is 8.5; 2mol / L hydrochloric acid solution until the pH of the eluate is 4.5; then rinse with 5 times the column volume of deionized water to complete the activation. Load the concentrated extract, then use 1000L 2.5mol / L ammonia water to elute, the elution rate is 6BV / h, and collect the eluate when the pH of the cationic column effluent is >7, when the co...

preparation example 2

[0035] Take 10kg of fresh mulberry branches (Sangteyou No. 2), crush them, add 150L of water, add in 2 times, extract by decoction for 3 hours each time, combine the extracts, and filter to remove insoluble matter. The extract was thermally concentrated until the solid content reached 8%, and it was transferred to an alcohol precipitation tank, and 2367.9 g of absolute ethanol (3 L) was added under a stirring blade of 300 rpm. After the ethanol was added, the stirring was stopped, and the alcohol was precipitated for 24 hours, and the supernatant was taken as the sample solution for the cationic resin column. Use 002SC type strongly acidic styrenic cationic resin 5kg packing column, according to the method for embodiment 3 Cationic resin is activated. Load the extract that has been concentrated and alcohol-precipitated, and then use 100L5mol / L potassium chloride to elute at a rate of 5BV / h. Use 20% silicotungstic acid to detect the effluent, and start collecting when white pre...

preparation example 3

[0043] Take 100g of fresh mulberry (white mulberry), crush it, add 300ml of alcoholic water, add in 2 times, heat and reflux each time to extract

[0044] After 1 h, the extracts were combined, and the insoluble matter was removed by filtration to obtain a crude extract. The crude extract was concentrated by heat until the solid content reached 2%, and kept at 25°C as the sample solution for the cationic resin column.

[0045] Use 5g of 732 type strongly acidic styrene-based cationic resins to pack the column, and use 2.5mol / L hydrochloric acid solution to wash until washing

[0046] The pH of the effluent is 3.5; wash with 1.5mol / L sodium hydroxide solution until the pH of the eluate is 8.0; wash with 2.5mol / L hydrochloric acid solution until the pH of the eluate is 3.5; then use 3 times the column volume of deionized water Rinse to complete activation. Load the concentrated extract, then use 3L 0.1mol / L ammonia water to elute, the elution rate is 10BV / h, and collect the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com