Preparation method and application of Co-CDs(at)NM photocatalyst

A photocatalyst and co-cds technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems that are not suitable for ppb level NO removal, and achieve low equipment requirements, simple operation, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Dissolve 2.86 g of 2-aminoterephthalic acid in a mixed solution of 40 mL DMF and 10 mL of anhydrous methanol, then add 2.86 mL of titanium isopropoxide, and place the mixture in a hydrothermal reaction Kettle, and placed in an oven at 110 ° C for 72 hours, then let it cool down to room temperature;

[0034] 2) Soak and wash the solid obtained by filtering in 1) with DMF and methanol respectively overnight, and then filter with suction to obtain the solid;

[0035] 3) Dry the solid obtained in 2) in vacuum to obtain NH 2 -MIL-125.

[0036] 2. Synthesis of Co-CDs@NM photocatalyst

Embodiment 2

[0038] (1) Dissolve 136.77 mg cobalt gluconate in 30 mL ethanol / water (9:1) solution, add 300 mg NH 2 - After stirring the MIL-125 for 6 hours, the solid was obtained by suction filtration with ethanol / water (9:1) solution.

[0039] (2) Vacuum-dry the obtained solid at 45°C for 8h, then put the dried solid into a tube furnace, and in a nitrogen atmosphere, raise the temperature to 240°C at a rate of 5°C / min and then calcinate for 2h to obtain the Co-CDs@NM photocatalyst.

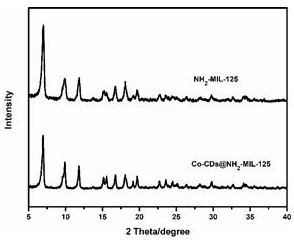

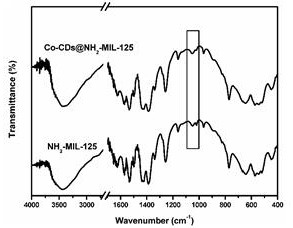

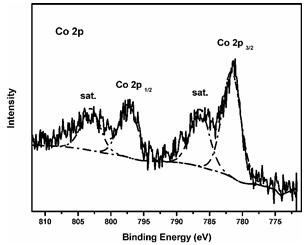

[0040] The Co-CDs@NM obtained in this example was analyzed and tested, wherein the XRD spectrum of Co-CDs@NM was as follows figure 1 As shown, the FT-IR spectrum (Fourier transform infrared spectrometer (FT-IR)) is as figure 2 As shown, the XPS spectrum of Co 2p is as image 3 , indicating that the valence state of the cobalt dopant is Co II , UV-Vis spectrum such as Figure 4 As shown, the PL spectrum is shown as Figure 5 As shown, the EIS spectrum is as Figure 6 As shown, the transient photocurre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com