One-pot method for preparing 2, 4, 5-trifluoro-3-methoxybenzoic acid

A technology of methoxybenzoic acid and trifluorophthalic acid salt, applied in the field of pharmaceutical synthesis, can solve the problems of high price of tetrafluorophthalic acid, difficulty in purifying the target product, long process route, etc., and achieves easy industrialization. Short production and process routes, and the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

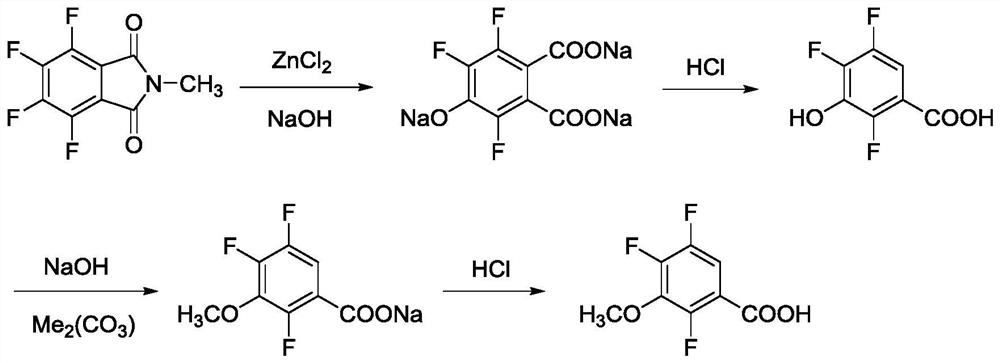

[0057] The present embodiment prepares the technique of 2,4,5-trifluoro-3-methoxybenzoic acid in one pot (processing route is as follows figure 1 shown), including the following steps:

[0058] (1) Using zinc chloride as a catalyst, place N-methyltetrafluorophthalimide in an alkaline environment, and undergo hydrolysis defluorination and hydroxylation to obtain 4-hydroxyl salt-3,5,6 - Trifluorophthalate;

[0059] Specifically, add water 3000kg, N-methyltetrafluorophthalimide 1000kg, 30% liquid caustic soda 2000kg and zinc chloride 50kg (N-methyltetrafluorophthalimide The molar ratio of sodium hydroxide to sodium hydroxide is 1:3.1, and the molar ratio of N-methyltetrafluorophthalimide to zinc chloride is 100:8.5), heat up to 100°C for 8 hours, and cool down after the reaction to below 35°C;

[0060] The reaction formula is shown in formula (I):

[0061]

[0062] (2) Add acid to the reaction system, and obtain 2,4,5-trifluoro-3-hydroxybenzoic acid through decarboxylation...

Embodiment 2

[0073] In this embodiment, a one-pot method for preparing 2,4,5-trifluoro-3-methoxybenzoic acid comprises the following steps:

[0074] (1) Using zinc chloride as a catalyst, place N-methyltetrafluorophthalimide in an alkaline environment, and undergo hydrolysis defluorination and hydroxylation to obtain 4-hydroxyl salt-3,5,6 - Trifluorophthalate;

[0075] Specifically, add 3000kg of water and 1000kg of N-methyltetrafluorophthalimide into the reactor, and then add 30% liquid caustic soda and zinc chloride, wherein, N-methyltetrafluorophthalimide The mol ratio of imine and sodium hydroxide is 1:2, and the mol ratio of N-methyltetrafluorophthalimide and zinc chloride is 100:10; the temperature is raised to 100° C. for 8 hours, and the reaction ends ( The liquid phase detects that the content of N-methyltetrafluorophthalimide in the reaction system is less than 1%) and then cools down to below 35°C;

[0076] (2) Add acid to the reaction system, and obtain 2,4,5-trifluoro-3-hydr...

Embodiment 3

[0081] In this embodiment, a one-pot method for preparing 2,4,5-trifluoro-3-methoxybenzoic acid comprises the following steps:

[0082] (1) Using zinc chloride as a catalyst, place N-methyltetrafluorophthalimide in an alkaline environment, and undergo hydrolysis defluorination and hydroxylation to obtain 4-hydroxyl salt-3,5,6 - Trifluorophthalate;

[0083] Specifically, add 3000kg of water and 1000kg of N-methyltetrafluorophthalimide into the reactor, and then add 30% liquid caustic soda and zinc chloride, wherein, N-methyltetrafluorophthalimide The molar ratio of imine to sodium hydroxide is 1:3.5, and the molar ratio of N-methyltetrafluorophthalimide to zinc chloride is 100:7; the temperature is raised to 100° C. for 9 hours, and the reaction ends ( The liquid phase detects that the content of N-methyltetrafluorophthalimide in the reaction system is less than 1%) and then cools down to below 35°C;

[0084] (2) Add acid to the reaction system, and obtain 2,4,5-trifluoro-3-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com