Preparation method of chitosan/sodium alginate dual-network hydrogel

A sodium alginate and chitosan technology, applied in biochemical equipment and methods, bone/connective tissue cells, cell culture support/coating, etc., can solve problems such as negative effects, and achieve low cytotoxicity and simple operation , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

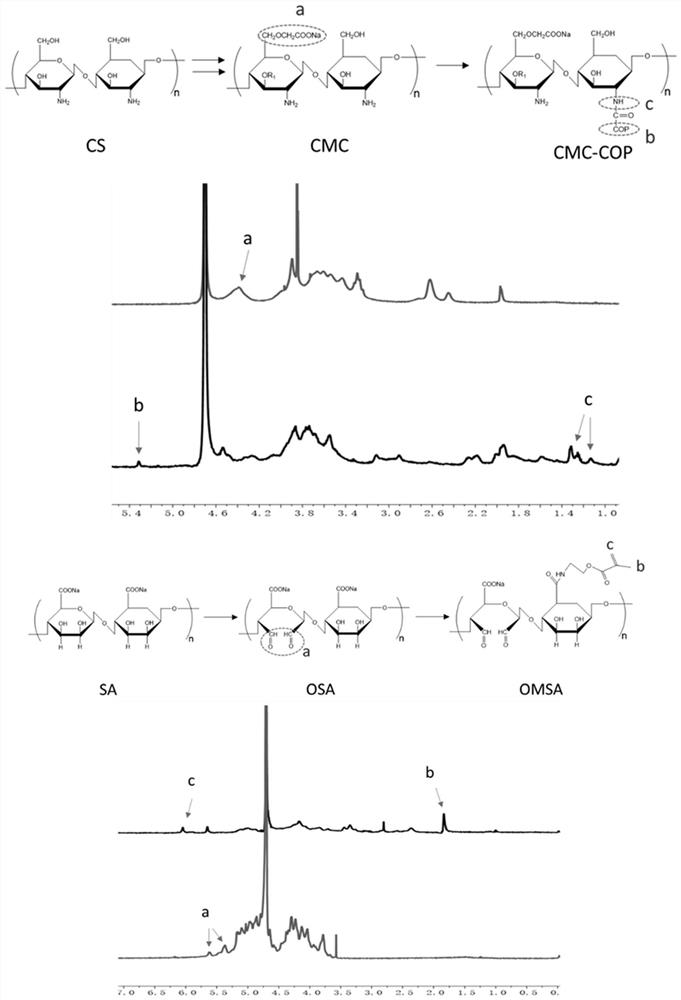

[0030] (1) 5g of chitosan was slowly added to 50mL of 50wt% NaOH aqueous solution prepared in advance, and placed at -20°C for 24h. Then, chitosan was thawed and dispersed in 150–200 mL of isopropanol to form a homogeneous solution. To this solution was added 8.5 g of chloroacetic acid and stirred at room temperature for 5 h (25 °C, 1500 rpm). The product was purified by dialysis against deionized water (Mw=3500) for 3 days, and then freeze-dried to obtain carboxymethyl chitosan (CMC). Then 1 g of carboxymethyl chitosan, 0.1 g of transglutaminase and 1 g of collagen peptide were dissolved in 30 mL of PBS (0.2 mol / L, pH=6.0) solution and mixed in a flask, and reacted at 40 ° C for 4 h (300rpm), keep in boiling water for 10min. After cooling to room temperature (25° C.), the product was dialyzed against deionized water (Mw=3500) for 4 days, and then freeze-dried to obtain carboxymethyl chitosan-collagen peptide (CMC-COP).

[0031] (2) First, 5 g of sodium alginate (SA) was un...

Embodiment 2

[0036] (1) the CMC-COP prepared in the embodiment 1, the OSA prepared in the embodiment 1 are dissolved in water, the pre-polymerization solution made, the mass percent of CMC-COP is 7.5%, the mass percent of OSA is 20%, The single network hydrogel OSA / CMC-COP was obtained by reacting at room temperature (25° C.) for 3 min in a glass sample vial.

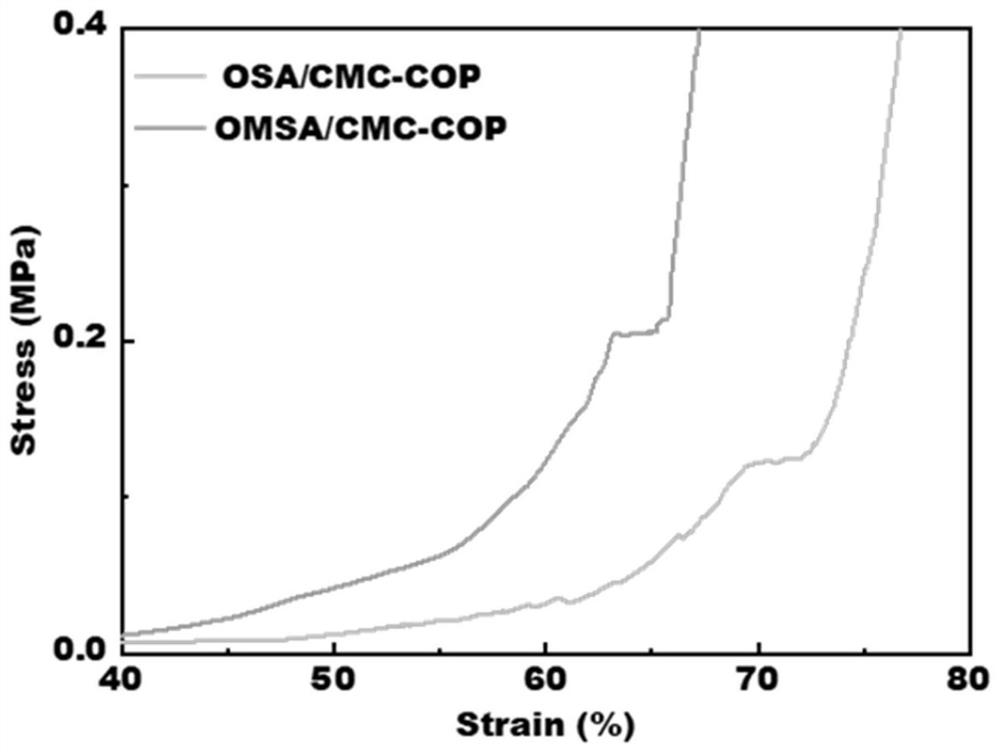

[0037] (2) the CMC-COP prepared in Example 1, the OMSA prepared in Example 1 and the I2959 photoinitiator are dissolved in water, and the pre-poly solution made, the mass percent of CMC-COP is 7.5%, the mass percent of OSA The percentage is 20%, the mass percentage of I2959 photoinitiator is 0.1%, and reacted in a glass sample bottle at room temperature (25° C.) for 3 minutes to obtain a single-network hydrogel. Then place the single-network hydrogel at a wavelength of 365nm and a power of 1mW / cm 2 The photocrosslinking occurred after irradiating with ultraviolet light for 15min to obtain the double network hydrogel OMSA / CMC-COP. ...

Embodiment 3

[0039] Example 3: The OSA / CMC-COP single network hydrogel and OMSA / CMC-COP double network hydrogel prepared in Example 2 were applied to this example.

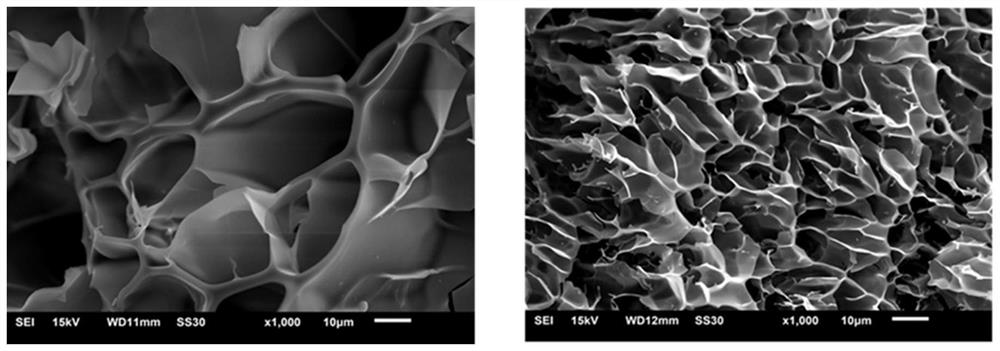

[0040] Put the prepared hydrogel into a freeze dryer, freeze-dry at -56°C for 12h, and then take it out. After spraying a thin layer of gold on the freeze-dried CMC-COP / OSA and CMC-COP / OMSA samples, the internal structure of the freeze-dried hydrogel was photographed by scanning electron microscopy. image 3 The internal microscopic morphology of the hydrogel is characterized by scanning electron microscopy. The hydrogel has a porous structure and is the preferred material for wound dressings. Its pore size is conducive to storing water, keeping the wound moist and breathable, and providing a good environment for cell growth. . image 3 (Left) is the internal microscopic morphology of OSA / CMC-COP single-network hydrogel after freeze-drying, with large pore size and different sizes. image 3 (Right) The right is the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com