Refining method for preparing high-purity non-caking fine-particle citric acid crystals

A refining method, citric acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of affecting the quality of citric acid-containing reagents, reducing the yield of citric acid, and reducing the strength of tablets, etc. , to achieve the effects of increased chloride and sulfate content, stable and feasible process, and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

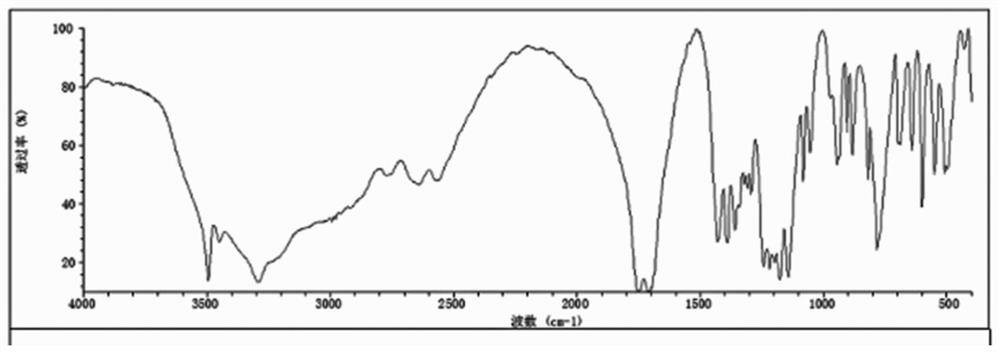

Image

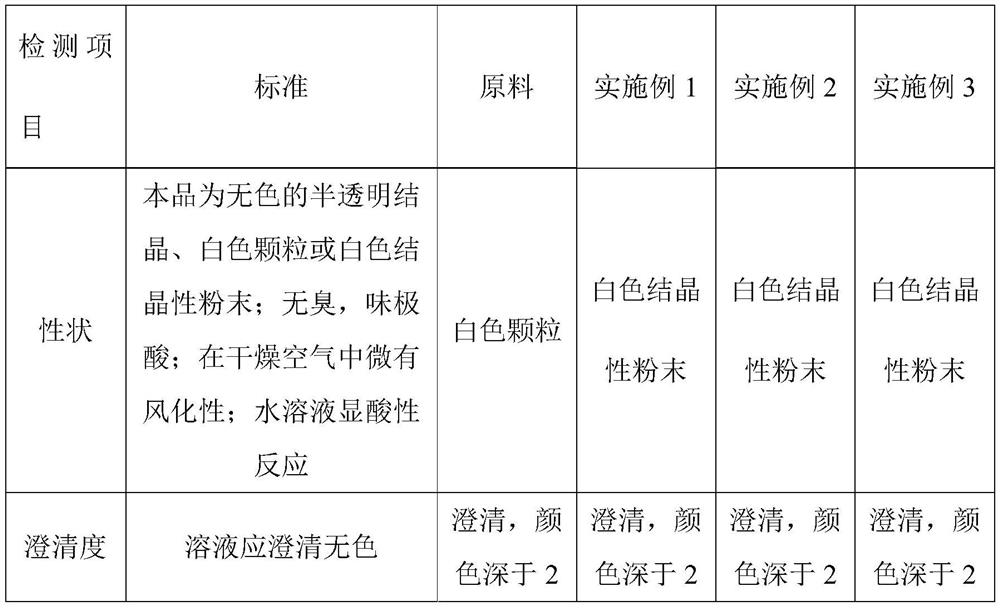

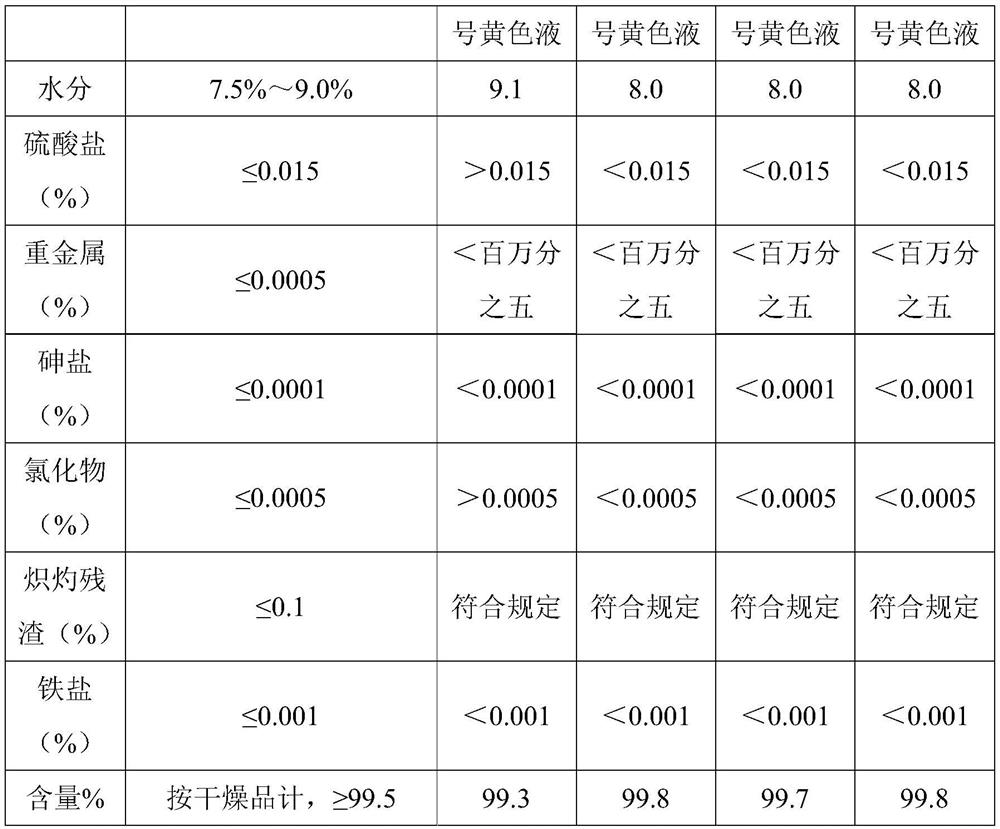

Examples

Embodiment 1

[0025] This embodiment provides a kind of refining method for preparing high-purity, non-caking fine-grained citric acid crystals:

[0026] S1. Dissolution and decolorization: Dissolve 100g of citric acid monohydrate and 35mL of water, add 0.4g of powdered medicinal activated carbon, heat up to 85°C, stir at a speed of 60-65r / min for 10-20min to decolorize.

[0027] S2. Filtration: Reduce the stirring speed to 10-12r / min, open the discharge valve, the liquid enters the 20um titanium rod filter for coarse filtration, and then enters the 0.5um titanium rod filter for fine filtration;

[0028] S3. Concentration and crystallization: Concentrate the substance liquid filtered in step S2 until the specific gravity of the concentrated solution is 1.35-1.45g / mL, the temperature is 60°C, the vacuum degree is -0.07MPa, and the concentration is concentrated to a relative density of 1.35g / mL. Reduce the stirring speed to 5-8r / min, slowly add 1.75g of citric acid seed crystals, continue t...

Embodiment 2

[0031] This embodiment provides a kind of refining method for preparing high-purity, non-caking fine-grained citric acid crystals:

[0032] S1. Dissolution and decolorization: Dissolve 100g of citric acid monohydrate and 40mL of water, add 0.3g of powdered medicinal activated carbon, heat up to 90°C, and stir at a speed of 60-65r / min for 10-20min.

[0033] S2. Filtration: Reduce the stirring speed to 10-12r / min, open the discharge valve, and the liquid enters the 20um titanium rod filter for coarse filtration, and then enters the 0.5um titanium rod filter for fine filtration.

[0034] S3. Concentration and crystallization: Concentrate the substance liquid filtered in step S2 until the specific gravity of the concentrated solution is 1.35-1.45g / mL, the temperature is 50°C, the vacuum degree is -0.07MPa, and the concentration is concentrated to a relative density of 1.40g / mL. Reduce the stirring speed to 5-8r / min, slowly add 1.70g of citric acid seed crystals, continue to stir f...

Embodiment 3

[0037] This embodiment provides a kind of refining method for preparing high-purity, non-caking fine-grained citric acid crystals:

[0038] S1. Dissolution and decolorization: Dissolve 100g of citric acid monohydrate and 45mL of water, add 0.5g of activated carbon, heat up to 95°C, stir at a speed of 60-65r / min for 10-20min to decolorize.

[0039] S2. Filtration: Reduce the stirring speed to 10-12r / min, open the discharge valve, the liquid enters the 20um titanium rod filter for coarse filtration, and then enters the 0.5um titanium rod filter for fine filtration;

[0040] S3. Concentration and crystallization: Concentrate the liquid filtered in step S2 until the specific gravity of the concentrated solution is 1.35-1.45g / mL, the temperature is 50°C, the vacuum degree is -0.07MPa, and the relative density is 1.45g / mL. Reduce the stirring speed to 5-8r / min, slowly add 1.82g of citric acid seed crystals, continue to stir for 30min, pass in cooling water to cool to 20°C, crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com