Quantum energy multifunctional interior wall coating and preparation method thereof

A quantum energy, interior wall paint technology, applied in the field of paint, can solve the problems of poor stain resistance, limited release of negative ions, easy cracking of interior wall latex paint, etc., to achieve the effect of strong adhesion and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

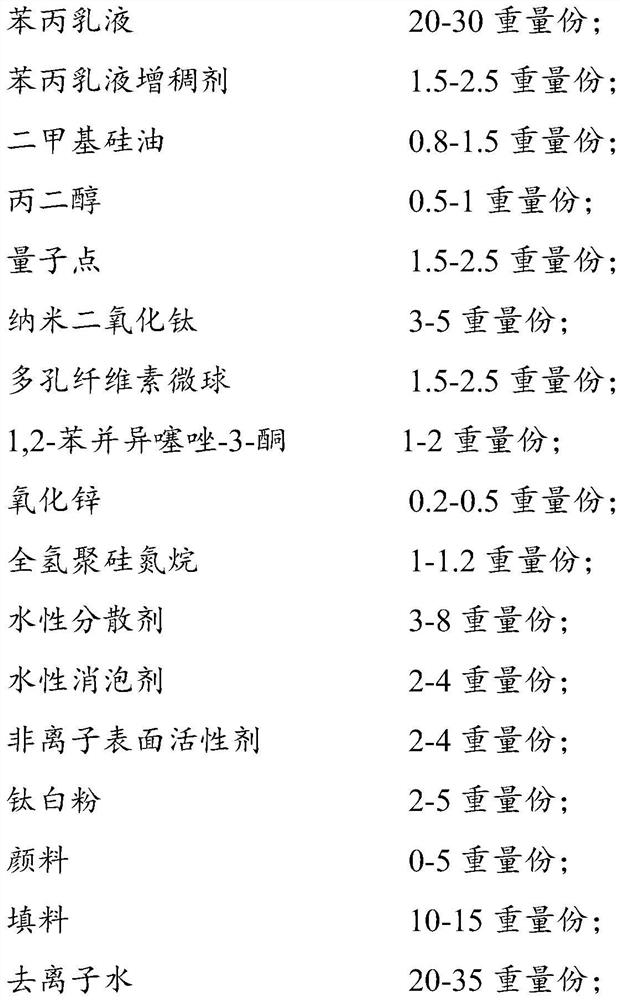

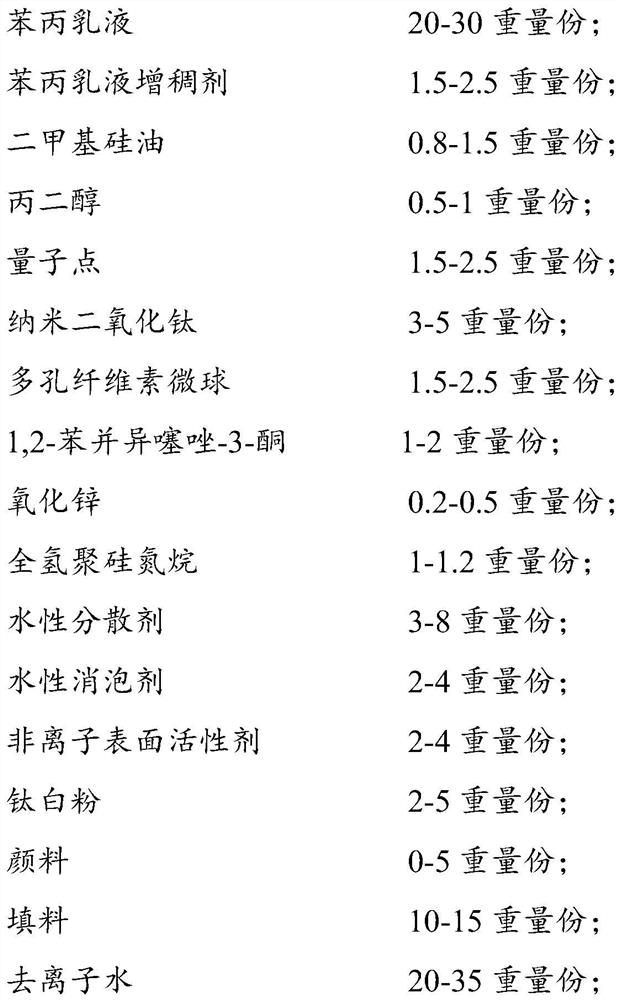

Method used

Image

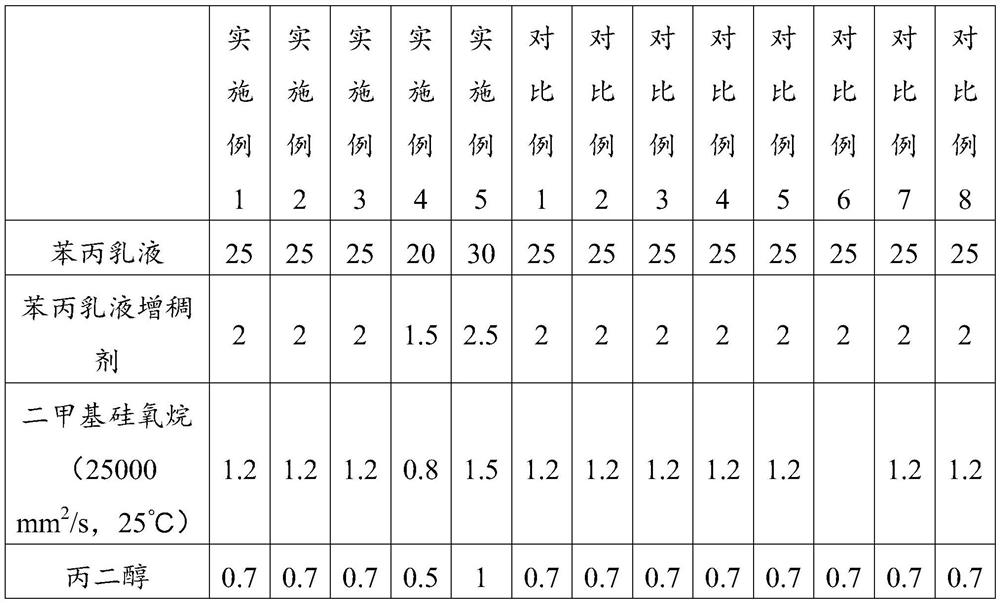

Examples

preparation example Construction

[0046] The preparation method of quantum energy multifunctional interior wall paint of the present invention, the steps are as follows:

[0047] Step 1, weighing each raw material according to composition and parts by weight;

[0048] Step 2. Stir and mix the propylene glycol and dimethylsiloxane evenly;

[0049] Step 3, continue to add deionized water to the reaction kettle, stir and mix evenly;

[0050] Step 4, continue to add 1,2-benzisothiazol-3-one, zinc oxide, perhydropolysilazane, water-based dispersant, nonionic surfactant, titanium dioxide, pigments and fillers to the reactor, and stir well mixed;

[0051] Step 5, continue to add quantum dots to the reaction kettle, stir and mix evenly;

[0052] Step 6, continue to add nano-titanium dioxide and porous cellulose microspheres in the reactor, stir and mix;

[0053] Step 7. Continue to add styrene-acrylic emulsion, styrene-acrylic emulsion thickener and water-based defoamer to the reaction kettle, stir and mix evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com