Corrosion inhibitor for atmospheric and vacuum distillation unit and preparation method of corrosion inhibitor

A technology of atmospheric and vacuum device and corrosion inhibitor, which is applied in the field of corrosion inhibitor and its preparation, can solve the problems of poor stability, poor versatility, and low effective temperature of the corrosion inhibitor, and achieves high corrosion inhibition rate, good oil solubility, Reduce the effect of complexing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

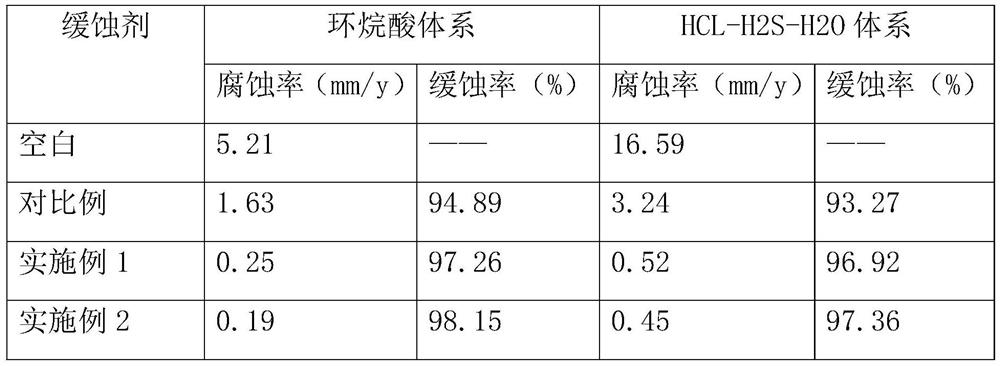

Examples

Embodiment 1

[0016] A corrosion inhibitor for atmospheric and vacuum devices, comprising the following components in parts by weight: 20 parts of monomethylamine, 10 parts of cinnamyl imidazoline, 10 parts of methyl trithion, 5 parts of chromate, 5 parts of a mixture of polyacrylic acid and organic phosphonic acid in a ratio of 1:1.

[0017] A kind of preparation method of the corrosion inhibitor that is used for atmospheric pressure device, with the mixture of monomethylamine, cinnamyl imidazoline, methyl trithion, chromate, polyacrylic acid and organic phosphonic acid in 1:1 ratio, Put it into the reaction kettle according to the weight ratio, stir and mix for 20 minutes under normal pressure, the stirring temperature is 50°C, and the corrosion inhibitor is obtained after mixing evenly.

[0018] Add pure water to the prepared corrosion inhibitor to adjust the pH value, and the pH value is controlled at 6.

Embodiment 2

[0020] A corrosion inhibitor for atmospheric and vacuum devices, comprising the following components in parts by weight: 15 parts of a mixture of monomethylamine, diethylamine, and tripropylamine in any proportion, cinnamyl imidazoline, and naphthenic acid imidazoline 15 parts of mixture in any proportion, 15 parts of mixture of methyl trisulfide, dimethyl disulfide, thiobenzoic acid in any proportion, 7 parts of silicate, mixture of polyacrylic acid and organic phosphonic acid in a ratio of 1:1 7 servings.

[0021] A method for preparing a corrosion inhibitor for atmospheric and vacuum devices, comprising a mixture of monomethylamine, diethylamine, tripropylamine in any proportion, cinnamyl imidazoline, naphthenic acid imidazoline in any proportion, methyltri The mixture of sulfur phosphorus, dimethyl disulfide, thiobenzoic acid in any proportion, silicate, polyacrylic acid and organic phosphonic acid in a ratio of 1:1 is put into a reaction kettle in proportion by weight and...

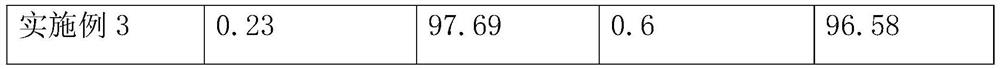

Embodiment 3

[0024] A corrosion inhibitor for atmospheric and vacuum devices, comprising the following components in parts by weight: 30 parts of a mixture of triethylenediamine and morpholine in any proportion, dodecylethylimidazoline and oleylamine 20 parts of a mixture of ethyl imidazoline in any proportion, 20 parts of a mixture of thiobenzoic acid and sulfurized isobutylene in any proportion, 10 parts of phosphate, and 10 parts of a mixture of polyacrylic acid and organic phosphonic acid in a ratio of 1:1.

[0025] A method for preparing a corrosion inhibitor for atmospheric and vacuum devices, comprising a mixture of triethylenediamine and morpholine in any proportion, a mixture of dodecyl ethyl imidazoline and oleylamine ethyl imidazoline in any proportion , a mixture of thiobenzoic acid and sulfurized isobutylene in any proportion, a mixture of phosphate, polyacrylic acid and organic phosphonic acid in a ratio of 1:1, is put into a reactor in proportion by weight and stirred and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com