Cobalt disulfide-tin disulfide composite particle and preparation method and application thereof

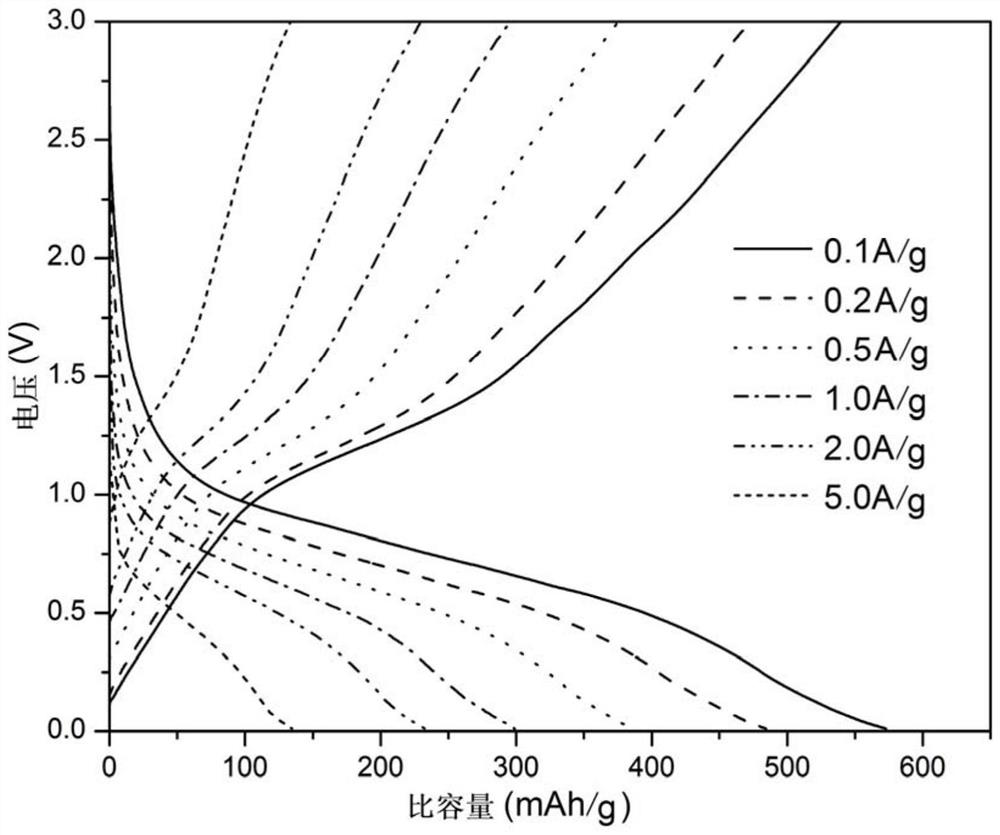

A technology of cobalt disulfide and tin disulfide, used in secondary batteries, electrochemical generators, active material electrodes, etc., can solve problems such as poor conductivity, limited popularization and application, and achieve reduced volume expansion, high mobility, and volume. Small swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of cobalt disulfide-tin disulfide composite particle, its preparation method comprises the following steps:

[0035] 1) 291.0mg of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 328.4mg of 2-methylimidazole (the molar ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1:4) were dispersed in 20mL of methanol, stirred evenly, left standing at room temperature for 24h, centrifuged, and washed with methanol Precipitate the product 3 times, and dry it in vacuum at 60°C for 3 hours to obtain the zeolite imidazolate framework material (ZIF-67);

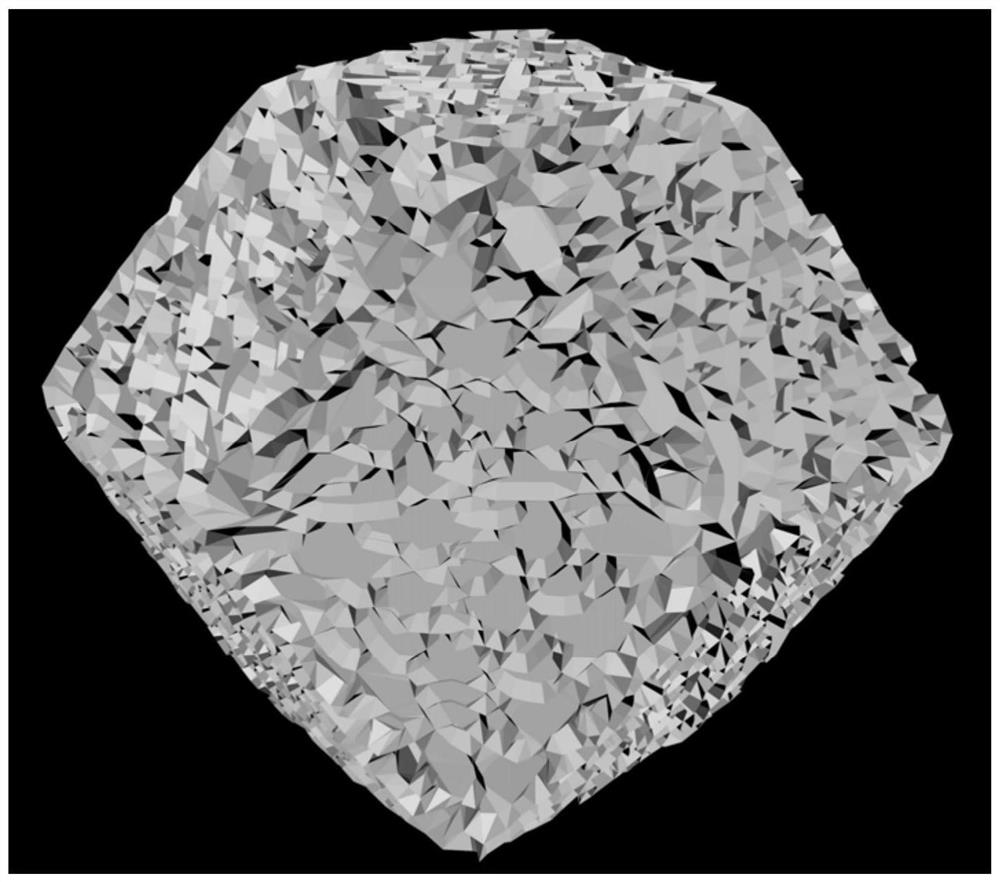

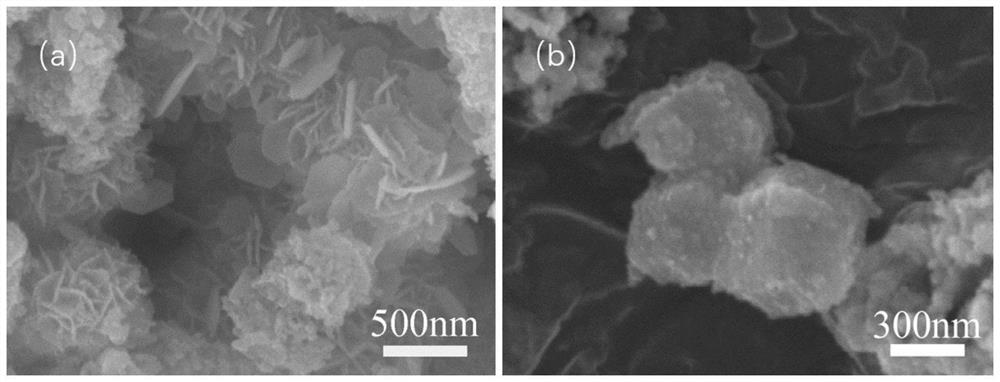

[0036] 2) Mix 150mg of zeolite imidazolate framework material and 300mg of sulfur powder evenly, place in nitrogen atmosphere, raise the temperature to 600°C at a rate of 2°C / min, and vulcanize at constant temperature for 3 hours to obtain cobalt disulfide particles;

[0037] 3) Disperse 40mg of cobalt disulfide particles in 40mL of ethanol, then add 112.7mg of thioacetamide to obtain solution A, and 263.0mg ...

Embodiment 2

[0039] A kind of cobalt disulfide-tin disulfide composite particle, its preparation method comprises the following steps:

[0040] 1) 291.0mg of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 328.4mg of 2-methylimidazole (the molar ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1:4) were dispersed in 20mL of methanol, stirred evenly, left standing at room temperature for 24h, centrifuged, and washed with methanol Precipitate the product 3 times, and dry it in vacuum at 60°C for 3 hours to obtain the zeolite imidazolate framework material (ZIF-67);

[0041] 2) Mix 150mg of zeolite imidazolate framework material and 300mg of sulfur powder evenly, place in nitrogen atmosphere, raise the temperature to 600°C at a rate of 2°C / min, and vulcanize at constant temperature for 3 hours to obtain cobalt disulfide particles;

[0042] 3) Disperse 40 mg of cobalt disulfide particles in 20 mL of ethanol, then add 56.3 mg of thioacetamide to obtain solution A, and 263.0 ...

Embodiment 3

[0044] A kind of cobalt disulfide-tin disulfide composite particle, its preparation method comprises the following steps:

[0045] 1) 291.0mg of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 328.4mg of 2-methylimidazole (the molar ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1:4) were dispersed in 20mL of methanol, stirred evenly, left standing at room temperature for 24h, centrifuged, and washed with methanol Precipitate the product 3 times, and dry it in vacuum at 60°C for 3 hours to obtain the zeolite imidazolate framework material (ZIF-67);

[0046] 2) Mix 150mg of zeolite imidazolate framework material and 300mg of sulfur powder evenly, place in nitrogen atmosphere, raise the temperature to 600°C at a rate of 2°C / min, and vulcanize at constant temperature for 3 hours to obtain cobalt disulfide particles;

[0047]3) Disperse 40mg of cobalt disulfide particles in 60mL of ethanol, then add 169.0mg of thioacetamide to obtain solution A, and 263.0mg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com