Processing method of candied green plums

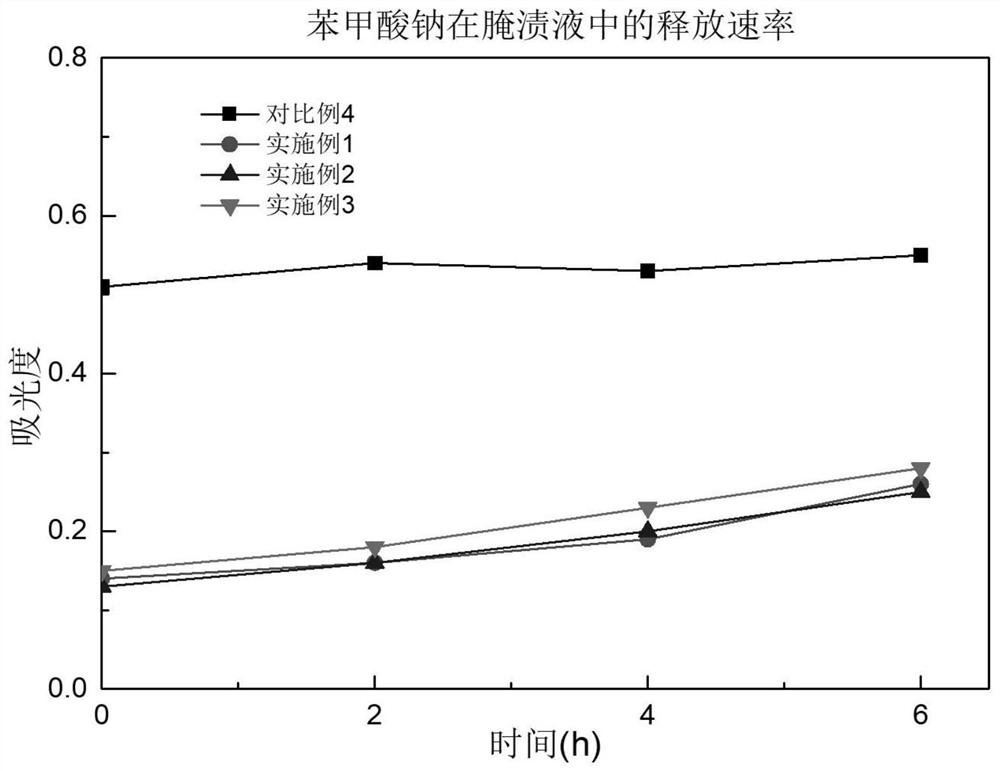

A processing method and technology of candied green plums, which are applied in the confectionary industry, the function of food ingredients, and the preservation of food ingredients as antimicrobials, etc., can solve the problems of poor preservation performance of candied fruit and heavy astringency of the original fruit of candied green plums, and achieve sweetness. The effect of high alcohol content, sweet taste, and reducing the amount of sugar used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

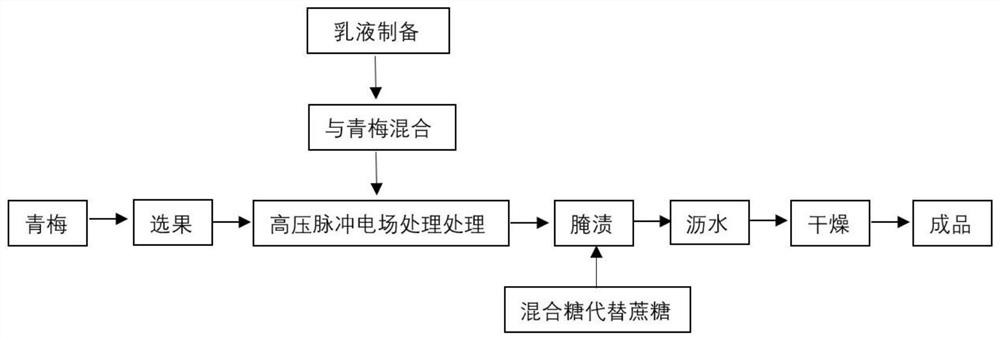

Embodiment 1

[0037] (1) Select fresh greengage fruits with a maturity of 70% and uniform size, remove soft and shriveled inferior fruits with obvious mechanical damage and disease, and wash them with clean water for later use;

[0038] (2) Fructose, xylitol, ammonium glycyrrhizinate, glycine, erythritol, and sucralose are added to water, and prepared to obtain a sugar solution, wherein the mass concentration of each substance is: fructose 20%, xylitol 25%, Ammonium glycyrrhizinate 0.7‰, glycine 0.1‰, erythritol 0.06‰, sucralose 0.015‰;

[0039] (3) Sodium caseinate is dissolved in water, then add sodium benzoate, make the mass percent concentration of sodium caseinate and bacteriostat in the mixed solution be respectively 1wt% and 0.02wt%, after stirring and mixing, carry out shear processing, The shear time is 1min, the shear rate is 20×1000rpm, and then ultrasonic treatment is performed, the ultrasonic time is 10min, the interval is 2s, the power is 120w, and the emulsion is obtained;

...

Embodiment 2

[0046] (1) Select fresh greengage fruits with a maturity of 70% and uniform size, remove soft and shriveled inferior fruits with obvious mechanical damage and disease, and wash them with clean water for later use;

[0047] (2) Add fructose, xylitol, ammonium glycyrrhizinate, glycine, erythritol, and sucralose into water, and prepare a sugar solution, wherein the concentration of each substance is: fructose 30%, xylitol 30%, licorice Ammonium acid 0.6‰, glycine 0.09‰, erythritol 0.07‰, sucralose 0.02‰;

[0048] (3) Dissolve 0.5% sodium caseinate and 0.015% sodium benzoate in water and mix them for shearing treatment, the shearing time is 2min, the shearing rate is 15×1000rpm, and then ultrasonic treatment is performed, the ultrasonication time is 12min, and the interval is 1s , power 100w;

[0049] (4) The emulsion that step (3) is obtained is mixed with green plum, and carries out high-voltage pulse electric field treatment, and electric field intensity is 30kV / cm, and pulse ...

Embodiment 3

[0055] (1) Select fresh greengage fruits with a maturity of 70% and uniform size, remove soft and shriveled inferior fruits with obvious mechanical damage and disease, and wash them with clean water for later use;

[0056] (2) Add fructose, xylitol, ammonium glycyrrhizinate, glycine, erythritol, and sucralose into water, and prepare a sugar solution, wherein the concentration of each substance is: fructose 25%, xylitol 20%, licorice Ammonium acid 0.8‰, glycine 0.08‰, erythritol 0.08‰, sucralose 0.01‰;

[0057] (3) Dissolve 0.8% sodium caseinate and 0.01% sodium benzoate in water and mix them for shearing treatment, the shearing time is 2min, the shearing rate is 10×1000rpm, and then ultrasonic treatment is performed, the ultrasonication time is 15min, and the interval is 1s , power 150w;

[0058] (4) The emulsion that step (3) is obtained is mixed with Ome, carry out high-voltage pulsed electric field treatment, and electric field strength is 40kV / cm, and pulse width is 2 μ s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com