Template for tissue engineering material and tissue engineering material

A technology of tissue engineering and templates, applied in medical science, blood vessels, prostheses, etc., can solve the problems of coagulation matrix adhesion, easy sliding, and exposed skeleton fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

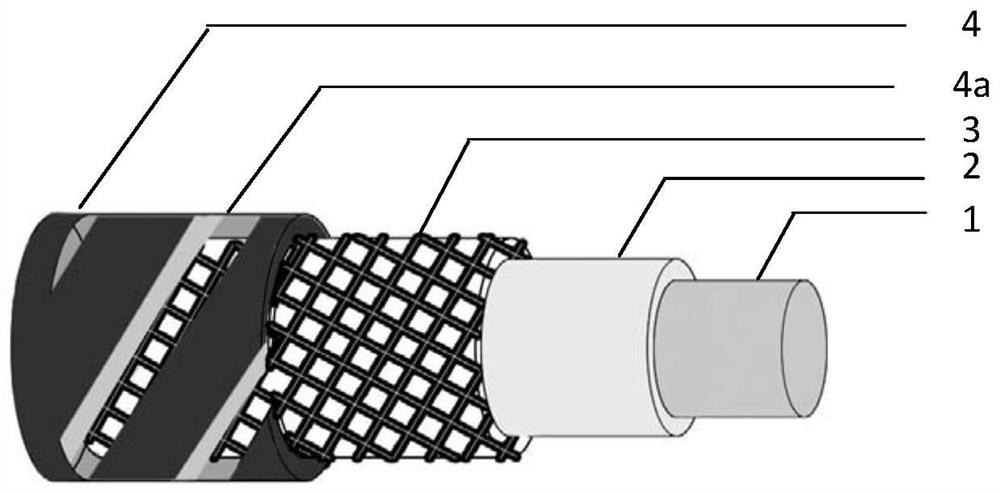

[0051] The tissue engineering material template provided in this embodiment is a tissue engineering blood vessel template, which includes a support body, that is, an inner core, an anti-exposure layer, a reticular fiber skeleton layer, and a protective layer, that is, an overcoat from the inside to the outside; the protective layer is provided with Hollow structure; the protective layer is arranged outside the mesh fiber skeleton layer, and the inner diameter of the protective layer matches the outer diameter of the mesh fiber skeleton layer.

[0052] The template preparation process includes the following steps:

[0053] 1. Select a silicone tube as the support, with an outer diameter of 2 mm and an inner diameter of 1 mm; the outer diameter of the support determines the inner diameter of the prepared tissue engineering blood vessel.

[0054] 2. Using PDS: gelatin = 1:2 (mass ratio) as the raw material, the biodegradable layer was prepared on the surface of the silicone tube ...

Embodiment 2

[0066] The template preparation process includes the following steps:

[0067] 1. A polyurethane tube with an outer diameter of 4 mm and an inner diameter of 2 mm is used as a support body, and the outer diameter of the support body determines the inner diameter of the prepared tissue engineering blood vessel.

[0068] 2. Using PLGA and PEO as raw materials, high-voltage electrospinning technology is used to prepare an anti-exposure layer on the surface of the polyurethane tube. The specific method is: insert a stainless steel rod with a suitable diameter into the above polyurethane tube as a receiving rod, and use chloroform: methanol =5:1 (volume ratio) as a solvent, PLGA:PEO=1:1 (mass ratio) as a solute, prepare an electrospinning solution with a concentration of 0.28g / ml, use a 20G needle, and set a flow rate of 8mL / h. A DC voltage of 16kV is applied to the spinning needle, and a grounded stainless steel plate is used as the conductive receiving plate. The receiving rod is...

Embodiment 3

[0076] 1. A silicone tube with an outer diameter of 5 mm and an inner diameter of 3 mm is used as a support body, and the outer diameter of the support body determines the inner diameter of the prepared tissue engineering blood vessel.

[0077] 2. Using P(3HB-co-4HB) and PEO as raw materials, high-voltage electrospinning technology is used to prepare an anti-exposure layer on the surface of the silicone tube. The specific method is: insert a stainless steel rod with a suitable diameter into the above-mentioned silicone tube as a receiving Rod, with chloroform: methanol = 5:1 (volume ratio) as solvent, P(3HB-co-4HB): PEO = 1:0.5 (mass ratio) as solute, and prepare electrospinning with a concentration of 0.3g / ml Liquid, using a 19G needle, set the flow rate to 8mL / h, apply a DC voltage of 14kV to the needle, use a grounded stainless steel plate as the conductive receiving plate, place the silicone tube between the conductive receiving plate and the needle, and the distance from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com