Flame-retardant heat-resistant polyvinyl chloride material and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of flame-retardant and heat-resistant polyvinyl chloride materials and their preparation, can solve problems such as unsatisfactory thermal stability, limited application range, and irrational flame retardancy, and achieve Wide range of use, easy industrial production, and the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

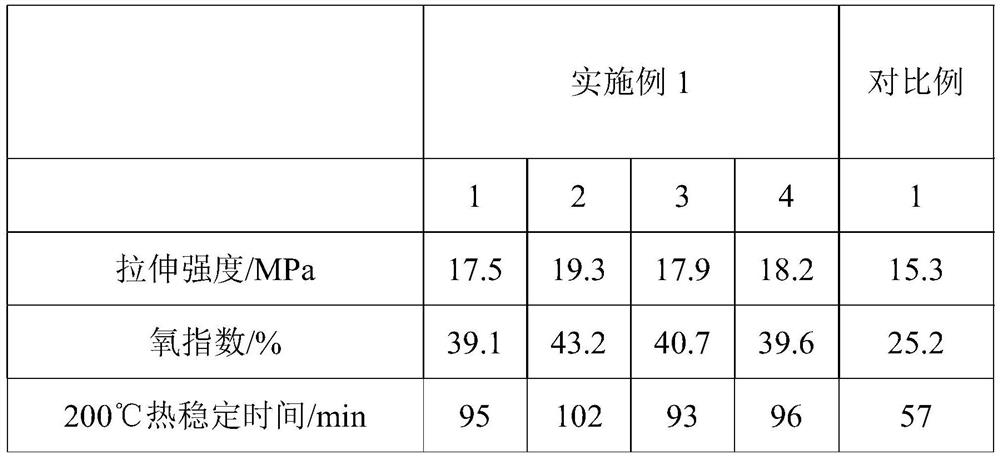

Examples

Embodiment 1

[0020] A flame-retardant and heat-resistant polyvinyl chloride material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 10 parts of butadiene rubber, 10 parts of maltodextrin, sodium diisobutylnaphthalene sulfonate 0.9 part, 0.16 part of two-2-ethylhexyl sodium sulfosuccinate, 0.15 part of zinc borate, 0.1 part of antioxidant, 0.2 part of methyl silicone oil, 0.8 part of vulcanizing agent; the mass ratio of the vulcanizing agent is 100: 20: 0.4 sulfur, fatty alcohol polyoxyethylene ether and dithiodimorpholine were ball milled in a ball mill for 1.5 hours, and the milling temperature was controlled at 50°C; the antioxidant was benzotriazole;

[0021] The preparation method of the flame-retardant heat-resistant polyvinyl chloride material comprises the following steps:

[0022] S1. Prepare raw materials: In parts by weight, weigh 100 parts of polyvinyl chloride resin powder, 10 parts of bu...

Embodiment 2

[0026] A flame-retardant and heat-resistant polyvinyl chloride material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 15 parts of butadiene rubber, 8 parts of maltodextrin, sodium diisobutylnaphthalene sulfonate 0.6 part, 0.13 part of two-2-ethylhexyl sodium sulfosuccinate, 0.25 part of zinc borate, 0.15 part of antioxidant, 0.4 part of methyl silicone oil, 1 part of vulcanizing agent; the mass ratio of the vulcanizing agent is 100: 24: 0.5 sulfur, fatty alcohol polyoxyethylene ether and dithiodimorpholine were ball milled in a ball mill for 1 hour, and the milling temperature was controlled at 60°C; the antioxidant was styrenated phenol;

[0027] The preparation method of the flame-retardant heat-resistant polyvinyl chloride material comprises the following steps:

[0028] S1. Prepare raw materials: In parts by weight, weigh 100 parts of polyvinyl chloride resin powder, 15 parts of but...

Embodiment 3

[0032] A flame-retardant and heat-resistant polyvinyl chloride material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 18 parts of butadiene rubber, 5 parts of maltodextrin, sodium diisobutylnaphthalene sulfonate 0.3 part, 0.1 part of bis-2-ethylhexyl sodium sulfosuccinate, 0.15 part of zinc borate, 0.1 part of antioxidant, 0.5 part of methyl silicone oil, 0.4 part of vulcanizing agent; the mass ratio of the vulcanizing agent is 100:28 0.6 sulfur, fatty alcohol polyoxyethylene ether and dithiodimorpholine are ball milled in a ball mill for 1 hour, and the milling temperature is controlled at 50-60° C.; the antioxidant is benzotriazole;

[0033] The preparation method of the flame-retardant heat-resistant polyvinyl chloride material comprises the following steps:

[0034] S1. Prepare raw materials: in parts by weight, weigh 100 parts of polyvinyl chloride resin powder, 18 parts of butadiene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com