Continuous esterification process based on acyclovir intermediate production mother liquor

A technology of intermediates and mother liquor, applied in the field of continuous esterification process, can solve the problems of inability to realize the recycling of mother liquor, inability to recycle catalysts, and huge production equipment, so as to reduce energy consumption, complete reaction, efficient recycling and comprehensive utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

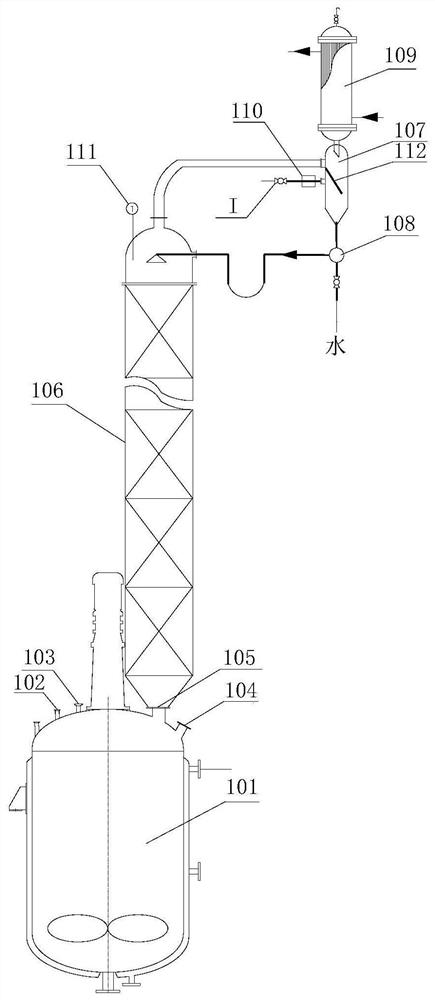

[0048] Such as figure 1 Shown, is the device used in the continuous esterification process based on the production of mother liquor of acyclovir intermediate of the present invention: a continuous production device in which esterification and rectification operations are carried out in combination, separated by reaction unit and rectification Unit composition, the reaction unit is used to realize the esterification reaction, and the rectification separation unit is used to realize the separation of the product ester from other materials. The gas phase material produced by the reaction unit is directly condensed and separated through the rectification unit to realize continuous esterification.

[0049] The reaction unit includes an esterification reactor 101 with a jacket structure and a stirring system. The upper part of the esterification reactor is equipped with a liquid feed port 102 and a liquid feed port 103 , a solid catalyst feed port 104 and a large-diameter gas phase ...

Embodiment 2

[0064] According to the production device set forth in Example 1, the trial production operation of the reclaimed mother liquor of the acyclovir intermediate diacetylguanine is as follows, the quality of the reclaimed mother liquor consists of 48% acetic acid, 51% acetic anhydride, and 1% of other organic matter (mainly guanine, xanthine, etc.), the mass percentage of used recovered ethanol is 94.5%.

[0065] First put 20Kg of sodium bisulfate, 100Kg of recovered mother liquor, and 90Kg of recovered ethanol into a 500L reactor, turn on stirring, jacket steam heating, and the power switch of the oil-water phase discriminator, and adjust the reflux ratio to the full reflux state to control the reactor The temperature is 90-100°C.

[0066] When the temperature at the top of the rectification tower is stable at 70.0 to 75.0°C (in this embodiment, the temperature at the top of the tower is stable at 70 to 71°C), the quantitative feeding system for recovering the mother liquor and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com